High-performance liquid detection method of alcohol amine cement grinding aid

A cement grinding aid and high-performance liquid phase technology, which is applied to the field of chromatographic detection of substances, can solve the problems of long detection time, can not meet the needs of rapid detection, etc., and achieves good linear relationship and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

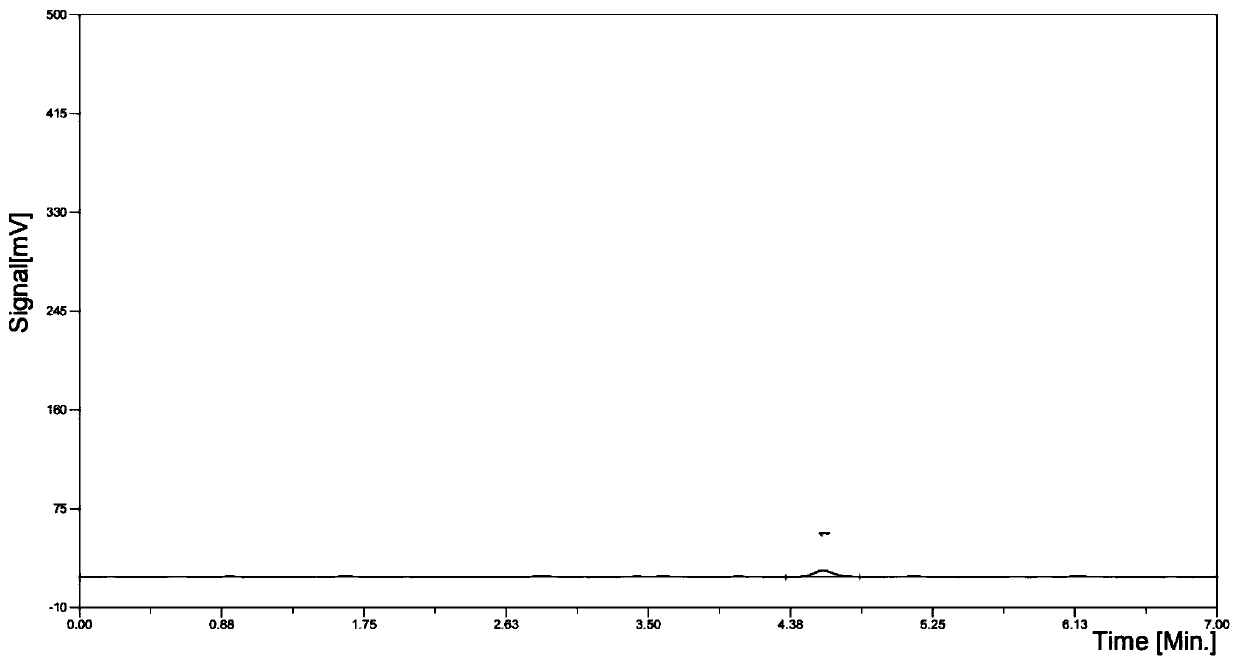

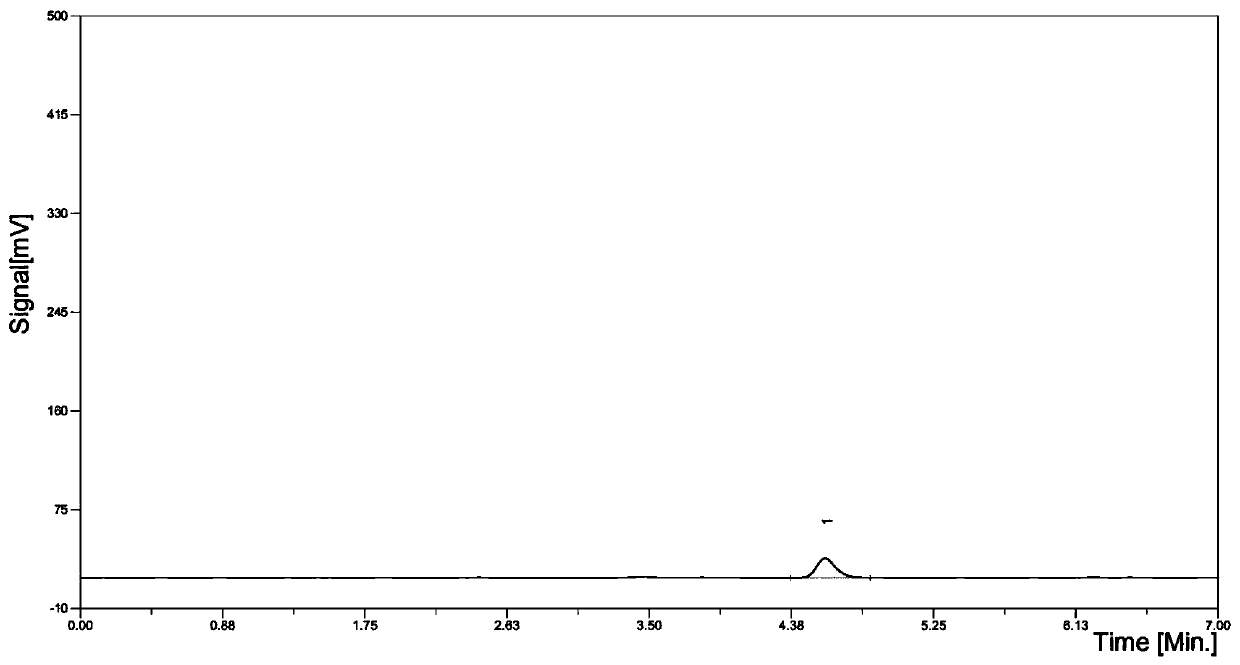

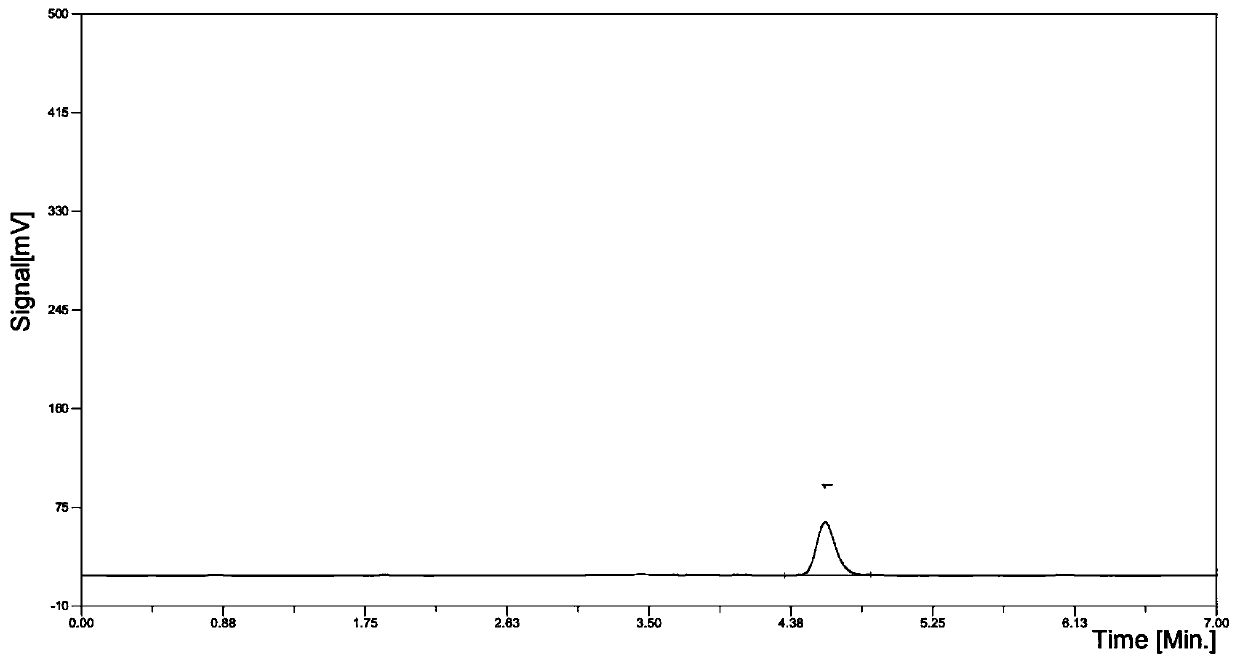

Image

Examples

Embodiment 1

[0034] This embodiment provides a high-efficiency liquid phase detection method for cement grinding aid diethanol monoisopropanolamine, comprising the following steps:

[0035] (1) Preparation of the reference substance solution and the test solution: Accurately weigh an appropriate amount of diethanol monoisopropanolamine reference substance, dissolve it with mobile phase and constant volume to obtain a stock solution of 10.0 mg / mL, and dilute it sequentially with mobile phase to determine Obtain the reference substance solution of 10.0, 20.0, 40.0, 60.0, 80.0 μ g / mL; Accurately weigh 100.0 mg of diethanol monoisopropanolamine test sample, place 10 mL volumetric flask, use mobile phase (methanol and 0.1% acetic acid The volume ratio of the aqueous solution is 80:20) to dissolve and constant volume to obtain the test solution, if the solution is turbid, filter it with a 0.22 μm filter membrane to obtain the test solution; and use the mobile phase as a blank solution;

[0036] ...

Embodiment 2

[0048] This embodiment detects the degree of separation of cement grinding aids diethanol monoisopropanolamine and triethanolamine under the detection method of the present invention, including the following steps:

[0049](1) Preparation of a mixed solution of diethanol monoisopropanolamine and triethanolamine: accurately weigh an appropriate amount of diethanol monoisopropanolamine reference substance and triethanolamine reference substance, dissolve and settle to volume with mobile phase to obtain diethanol monoisopropanolamine Alcohol amine and triethanolamine mixed solution stock solution, the concentration of diethanol monoisopropanolamine and triethanolamine in this mixed solution is 10.0mg / mL, and is diluted with mobile phase to obtain diethanol monoisopropanolamine and triethanolamine The concentration is 80.0μg / mL solution;

[0050] (2) Chromatographic conditions (high performance liquid chromatography (Shimadzu LC-20AT)):

[0051] Chromatographic column: Waters XBr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com