Ultrasound-assisted batched creep ageing forming device for wallboard, and application method of ultrasound-assisted batched creep ageing forming device

A creep aging forming, ultrasonic-assisted technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems that the precipitation rate of the strengthening phase has not been substantially improved, the precipitation efficiency of the strengthening phase is low, and the forming energy consumption is high. The effect of improving the efficiency of press forming, promoting dislocation migration, and improving the uniformity of properties

Active Publication Date: 2020-02-18

SUZHOU UNIV OF SCI & TECH

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Due to the low precipitation efficiency of the strengthening phase, in order to fully disperse and precipitate the strengthening phase, the creep aging forming process needs to be kept in a high temperature environment for a long time, resulting in a very low efficiency of the process

In addition, for mass-produced panels, the continuous heating and cooling process wastes a lot of heat energy, so the creep age forming of panels consumes a lot of energy

The National Patent Office has published a method of rapid creep aging forming with application number CN201710124448.8, a creep aging forming process with application number CN201410829364.0 and an aluminum alloy with application number CN201710353340.6 Alloy plate creep aging forming methods, although these methods can improve the creep aging forming efficiency of the wall plate to a certain extent, but each high temperature thermal cycle can only manufacture one piece of wall plate, there are still problems of low efficiency and high energy consumption question

The precipitation rate of the strengthening phase has not been substantially improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0051] The wall plate material is 2A12 aluminum alloy, the length of the wall plate blank is 1200 mm, the width is 800 mm, and the thickness is 8 mm. It is bent along the long direction of the wall plate, and the bending radius is 800 mm. Using the device and method of the present invention, a batch of creep Age forming 5 pieces.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

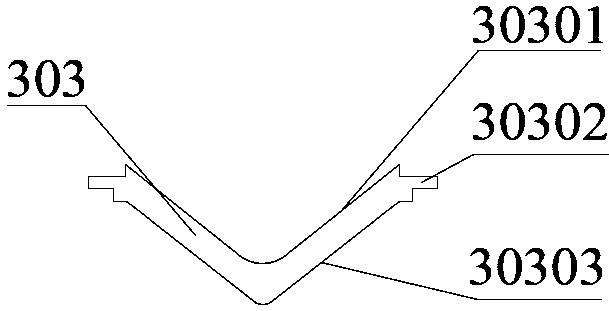

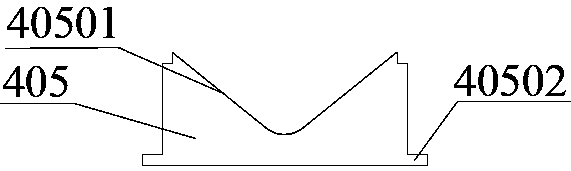

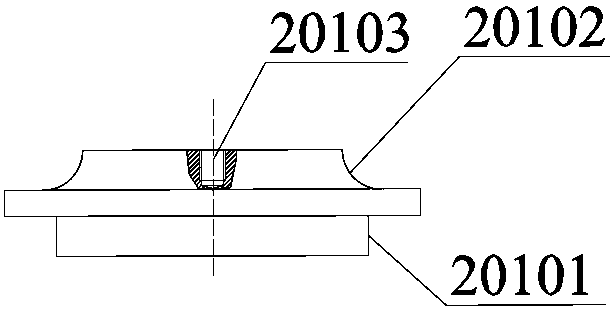

The invention discloses an ultrasound-assisted batched creep ageing forming device for a wallboard, and an application method of the ultrasound-assisted batched creep ageing forming device in order tosolve the problems about low production efficiency, large energy consumption and poor performance generated when the wallboard is subjected to creep ageing formation by adopting the existing device and method. The forming device comprises a pressing component, 1-10 circulating components, one supporting component, 4-40 locking bolts and upper and lower ultrasonic vibration systems. The forming device is used based on a thermal formation machine tool; when the forming device is in use, firstly a wallboard blank is placed on the supporting component; the upper ultrasonic vibration system is started; the thermal formation machine tool is used for providing pressure so that the circulating components are used one by one for pressing the wallboard blank to realize formation; afterwards the upper and lower ultrasonic vibration systems are simultaneously started; and the thermal formation machine tool provides a specific high-temperature environment to implement batched creep ageing formation. The device and the method disclosed by the invention can improve the separation efficiency of a strengthening phase, reduce the heating and cooling frequency, effectively improves the creep ageingformation efficiency of the wallboard and reduces energy consumption.

Description

technical field [0001] The invention belongs to the field of advanced manufacturing technology, and in particular relates to an ultrasonic-assisted batch creep aging forming device for wall panels and a method for using it. Background technique [0002] Creep aging forming technology is a process that combines aging strengthening and creep forming, and uses the high temperature creep characteristics of metals for forming. This process has the characteristics of simple operation, good repeatability, and high performance of formed parts. It is used in aerospace The field of siding production has broad application prospects. [0003] Due to the low precipitation efficiency of the strengthening phase, in order to fully disperse and precipitate the strengthening phase, the creep aging forming process needs to be kept in a high temperature environment for a long time, resulting in a very low efficiency of the process. In addition, for mass-produced panels, the continuous heating ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D31/00B30B7/02C21D9/00C22F1/04C22F3/00

CPCB21D31/00B30B7/02C21D9/0081C22F1/04C22F3/00

Inventor 马振武曹自洋殷振

Owner SUZHOU UNIV OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com