Spray free crucible for low impurity cast polycrystal and ingot monocrystal and preparation method thereof

A low-impurity, crucible technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of limited strength of the coating at room temperature, it is not suitable to introduce a large amount, and it is difficult to improve the hardness of the coating, so as to reduce the number of silicon ingots The effect of sticking pot phenomenon, less foundation material, and good coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

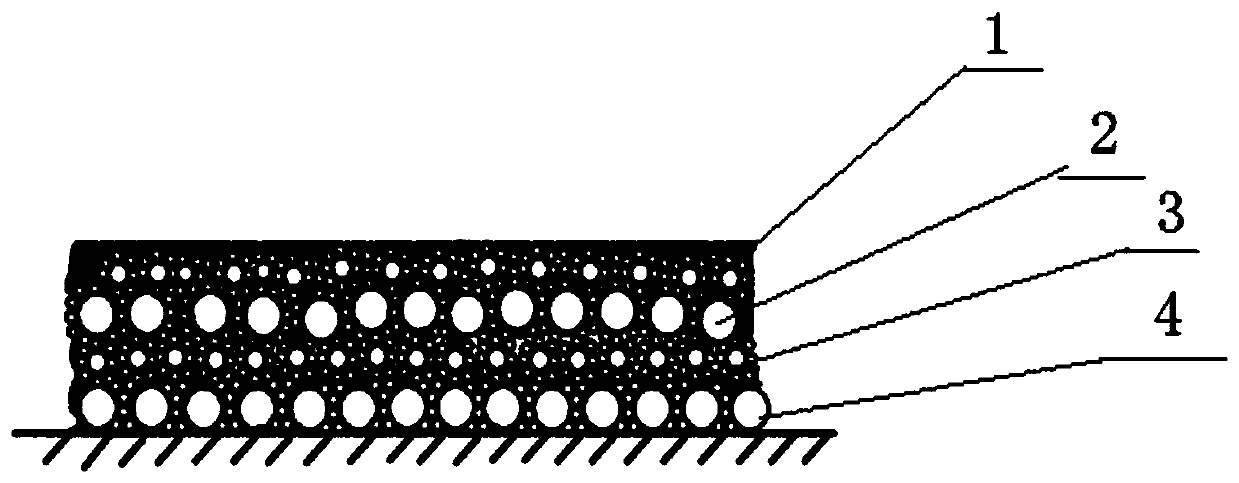

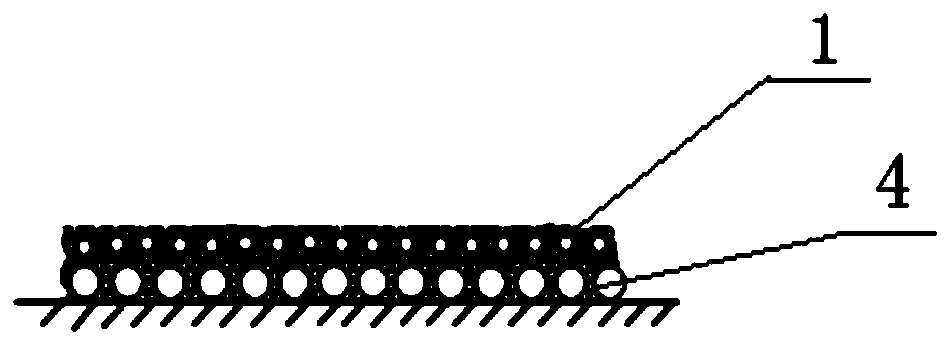

[0047] A spray-free crucible for cast polycrystalline and ingot single crystal with low impurities, comprising a crucible substrate or a high-purity substrate, the inner surface of the substrate is coated with a silicon nitride coating I above the liquid line region, and the inner surface of the substrate is Corresponding to the area below the silicon liquid line and the bottom of the crucible, silicon nitride coating II is coated with a two-layer structure including a base hard layer 4 and a surface protective layer 1; the silicon nitride coating Layer I sequentially includes a four-layer structure of base hard layer 4 , middle buffer layer 3 , middle hard layer 2 and surface protection layer 1 .

[0048] The preparation method of the spray-free crucible for cast polycrysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com