High-efficiency degreasing agent and production method

A degreaser and high-efficiency technology, applied in the field of high-efficiency degreaser, can solve the problems affecting the degreasing efficiency of steel parts, high foam volume, polluted workshop, etc., and achieve the effect of good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

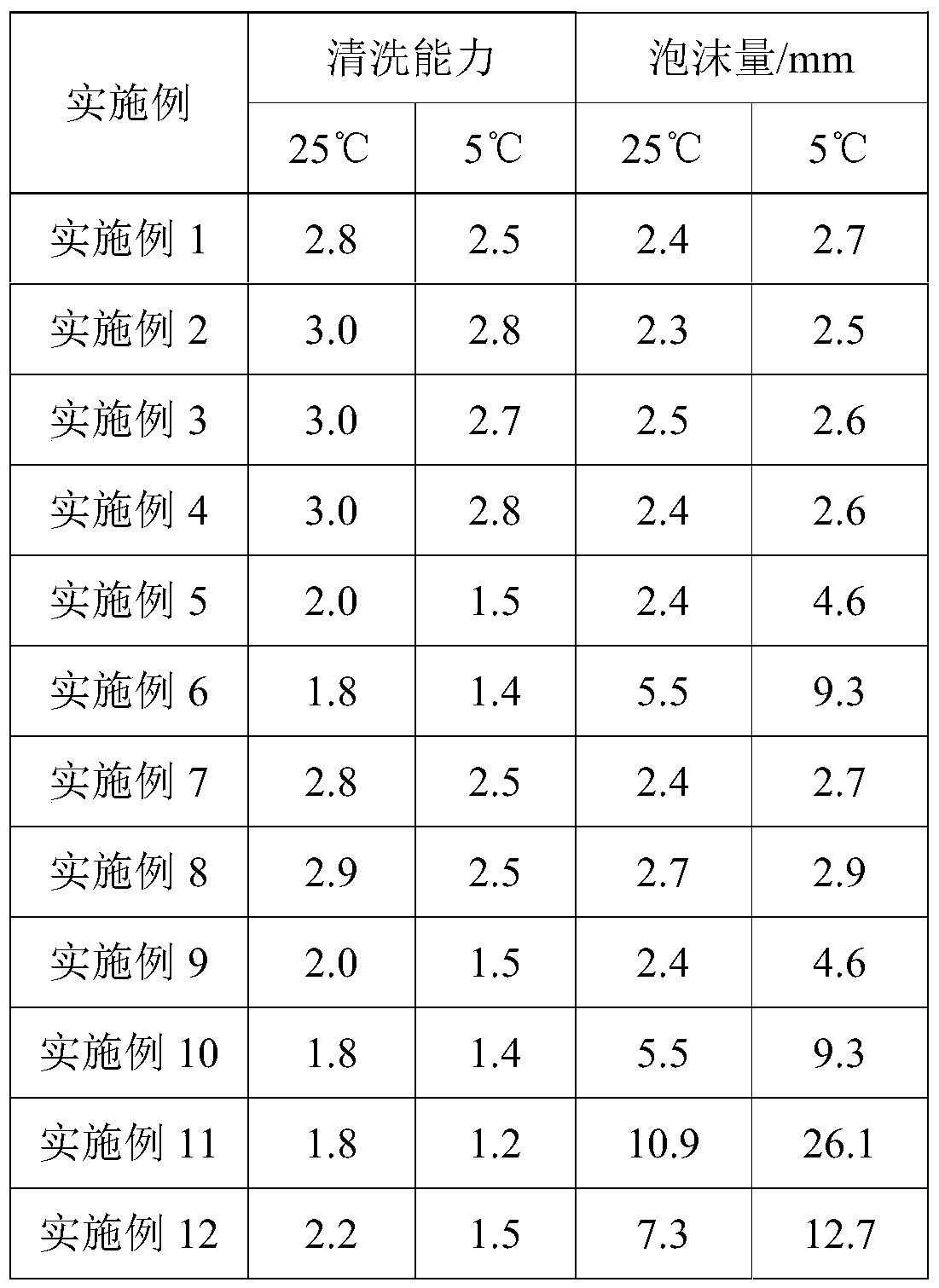

Examples

Embodiment 1

[0085] Embodiment 1 provides a kind of efficient degreasing agent, by weight, comprises 3 parts of hydroxides, 12 parts of carbonates, 4 parts of phosphates, 10 parts of silicates, 1.2 parts of emulsifiers, 4 parts of penetrants, 3 parts of dispersant, 2.5 parts of complexing agent.

[0086] The hydroxide is caustic soda; the carbonate is sodium carbonate; the phosphate is trisodium phosphate; the silicate is sodium metasilicate; and the sodium metasilicate is sodium metasilicate pentahydrate.

[0087] The emulsifier is sodium pyrophosphate; the dispersant is sodium dodecylsulfonate; the penetrating agent is polyoxyethylene octylphenol ether-10, polyoxyethylene octylphenol ether-5 and fatty alcohol poly A mixture of oxyethylene ethers; the weight ratio of polyoxyethylene octylphenol ether-10, polyoxyethylene octylphenol ether-5 and fatty alcohol polyoxyethylene ether in the penetrant is 1:0.75:0.6; the complex The mixture is a mixture of sodium gluconate and disodium edetate;...

Embodiment 2

[0094] Embodiment 2 provides a kind of efficient degreasing agent, by weight, comprises 3 parts of hydroxides, 12 parts of carbonates, 4 parts of phosphates, 10 parts of silicates, 1.2 parts of emulsifiers, 4 parts of penetrants, 3 parts of dispersant, 2.5 parts of complexing agent.

[0095] The hydroxide is caustic soda; the carbonate is sodium carbonate; the phosphate is trisodium phosphate; the silicate is sodium metasilicate; and the sodium metasilicate is sodium metasilicate pentahydrate.

[0096] The emulsifier is sodium pyrophosphate; the dispersant is a mixture of sodium lauroyl-N-methylglycine and cocamidopropyl sulfobetaine; in the dispersant, lauroyl-N-methyl The weight ratio of sodium glycine and cocamidopropyl hydroxysultaine is 1:0.75; the penetrating agent is polyoxyethylene octylphenol ether-10, polyoxyethylene octylphenol ether-5 and fatty alcohol poly A mixture of oxyethylene ethers; the weight ratio of polyoxyethylene octylphenol ether-10, polyoxyethylene o...

Embodiment 3

[0099] Embodiment 3 provides a kind of efficient degreasing agent, by weight, comprises 2 parts of hydroxides, 11 parts of carbonates, 3 parts of phosphates, 9 parts of silicates, 1 part of emulsifier, 3 parts of penetrating agent, 2 parts of dispersant, 2 parts of complexing agent.

[0100] The hydroxide is caustic soda; the carbonate is sodium carbonate; the phosphate is trisodium phosphate; the silicate is sodium metasilicate; and the sodium metasilicate is sodium metasilicate pentahydrate.

[0101]The emulsifier is sodium pyrophosphate; the dispersant is a mixture of sodium lauroyl-N-methylglycine and cocamidopropyl sulfobetaine; in the dispersant, lauroyl-N-methyl The weight ratio of sodium glycine and cocamidopropyl hydroxysultaine is 1:0.75; the penetrating agent is polyoxyethylene octylphenol ether-10, polyoxyethylene octylphenol ether-5 and fatty alcohol poly A mixture of oxyethylene ethers; the weight ratio of polyoxyethylene octylphenol ether-10, polyoxyethylene oc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com