Steel lining mounting machine for repairing top and side structures of subway tunnel

A technology for lining and tunneling, which is applied in the field of repairing the top and side structures of tunnels in the shield tunneling subway construction, achieving the effects of low labor intensity, high construction efficiency, and high construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

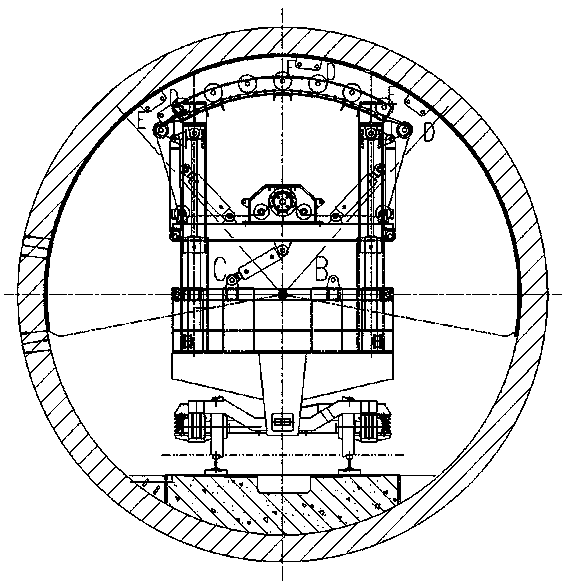

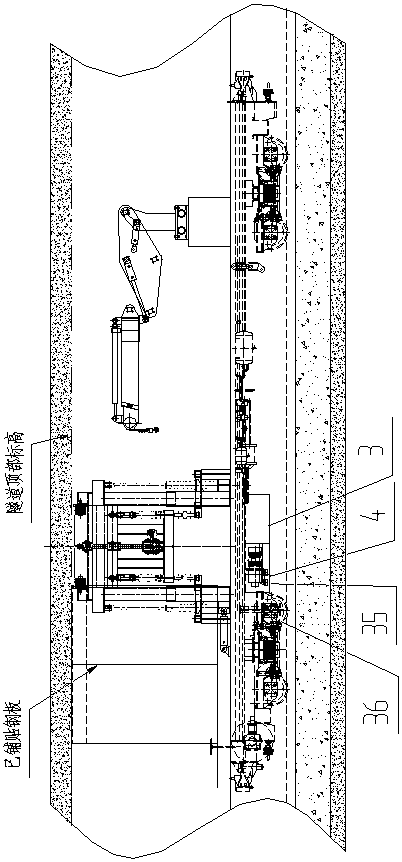

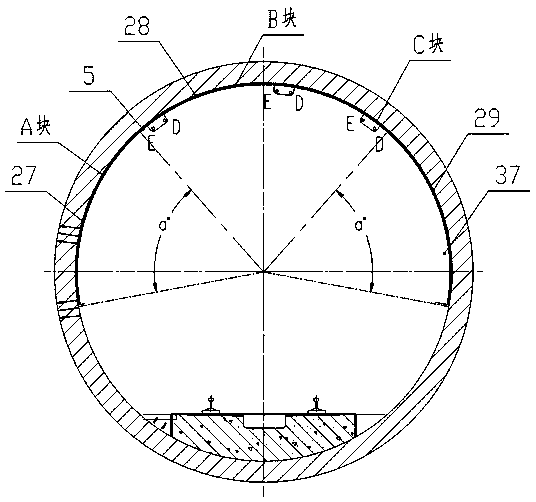

[0046] The technical scheme of the present invention is described in detail in conjunction with the accompanying drawings. According to the design requirements, the annular steel lining used for the repair of the side and top structures of the subway tunnel is divided into A block, C block and B block, and the prepared annular steel lining is divided into blocks. Blocks A, C and B are respectively placed on the flatbed truck, and the flatbed truck is dragged to the installation position of the steel lining by the rail traction locomotive, and then the preset lifting points D and E on the steel lining are respectively preset on the flatbed truck. The lifting arm end is connected, and the lifting device lifts the steel lining and places it on the steel lining installation machine. The steel lining is divided into blocks by the steel lining installation machine in the order of block A, block C, and block B, respectively. Ensure that the steel lining and the surface of the tunnel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com