Treatment process of phenolic waste ga

A technology for treating process and waste gas, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of increasing operating costs, increasing workload, and high operating costs, and reducing later operating costs, operating costs, and technology. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

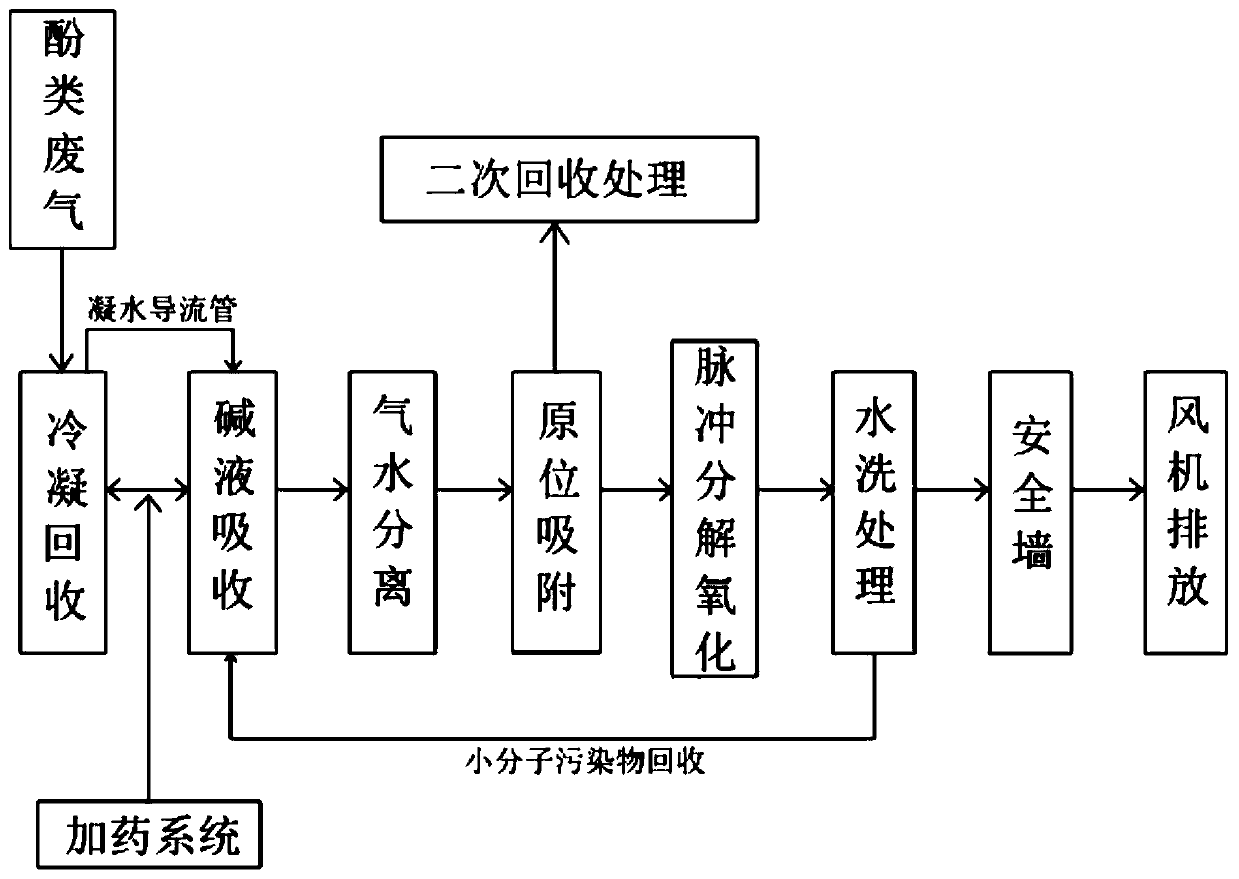

[0025] A treatment process for phenolic waste gas, such as figure 1 As shown, the specific operation steps are as follows:

[0026] Step 1. Condensation recovery: the collected phenolic waste gas is passed into the condensation recovery system for separation and recovery; phenolic gas is extremely volatile, so the first-level treatment chooses condensation recovery treatment, first of all, the phenol that needs to be treated intensively Condensation of phenolic waste gas for centralized recovery of phenolic waste gas. The recovered liquid phenolic waste gas can be used for the regeneration of phenolic substances.

[0027] At the same time, the air collecting pipe in the condensation recovery system is connected with a condensed water guide pipe, which is connected with the dynamic wave absorption tower. During the condensation treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com