Method for preparing ZIF-67 adsorbent by steam-assisted method and application of ZIF-67 adsorbent in cyclohexane adsorption

A ZIF-67, adsorbent technology, applied in the field of gas separation, can solve the problems of large solvent consumption, large waste liquid, low synthesis yield, etc., to save time and solvent, improve synthesis yield, and achieve selective adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

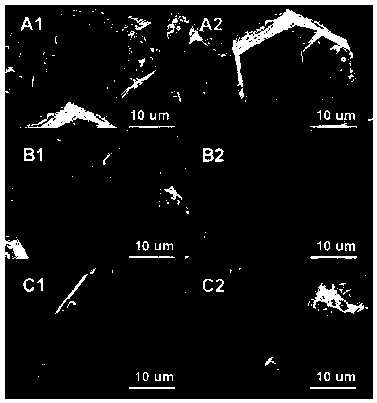

Image

Examples

Embodiment 1

[0023] (1) Co(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are mixed evenly at a molar ratio of 1:x (4≤x≤6), then suspended and placed on the top of the crucible in a polytetrafluoroethylene-lined reactor, and a certain amount of The methanol (MeOH) solvent makes the methanol liquid level lower than the top of the crucible, and the mixture is located above the solution to ensure that the solid and liquid phases are at different heights without contacting each other. The solid mixture and solution are the precursors of ZIF-67;

[0024] (2) Cover and seal the stainless steel reaction kettle where the precursor is located in step (1), transfer the reaction kettle to a dry box and react at 130-150°C for 24-48 hours; when transferring the reaction kettle to the dry box, handle it gently Handle with care to ensure that the solid mixture at the top of the crucible in the kettle will not spill into the solution;

[0025] Centrifuge and wash the product obtained in step (2) after cooling ...

Embodiment 2

[0028] (1) Co(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are mixed evenly at a molar ratio of 1:x (4≤x≤6), then suspended and placed on the top of the crucible in a polytetrafluoroethylene-lined reactor, and a certain amount of Acetone solvent (Ace), so that the acetone liquid level is lower than the top of the crucible, and the mixture is located above the solution to ensure that the solid and liquid phases are at different heights without contacting each other. The solid mixture and solution are the precursors of ZIF-67;

[0029] (2) Cover and seal the stainless steel reaction kettle where the precursor is located in step (1), transfer the reaction kettle to a dry box and react at 130-150°C for 24-48 hours; when transferring the reaction kettle to the dry box, handle it gently Handle with care to ensure that the solid mixture at the top of the crucible in the kettle will not spill into the solution;

[0030] (3) Centrifuge and wash the product obtained in step (2) after cooli...

Embodiment 3

[0033] (1) Co(NO3 ) 2 ·6H 2 O and 2-methylimidazole are mixed evenly at a molar ratio of 1:x (4≤x≤6), then suspended and placed on the top of the crucible in a polytetrafluoroethylene-lined reactor, and a certain amount of N,N-Dimethylformamide solvent (DMF), so that the DMF liquid level is lower than the top of the crucible, and the mixture is above the solution, ensuring that the solid and liquid phases are at different heights without contacting each other. The solid mixture and solution are ZIF-67 the precursor of

[0034] (2) Cover and seal the stainless steel reaction kettle where the precursor is located in step (1), transfer the reaction kettle to a dry box and react at 130-150°C for 24-48 hours; when transferring the reaction kettle to the dry box, handle it gently Handle with care to ensure that the solid mixture at the top of the crucible in the kettle will not spill into the solution;

[0035] (3) Centrifuge and wash the product obtained in step (2) after coolin...

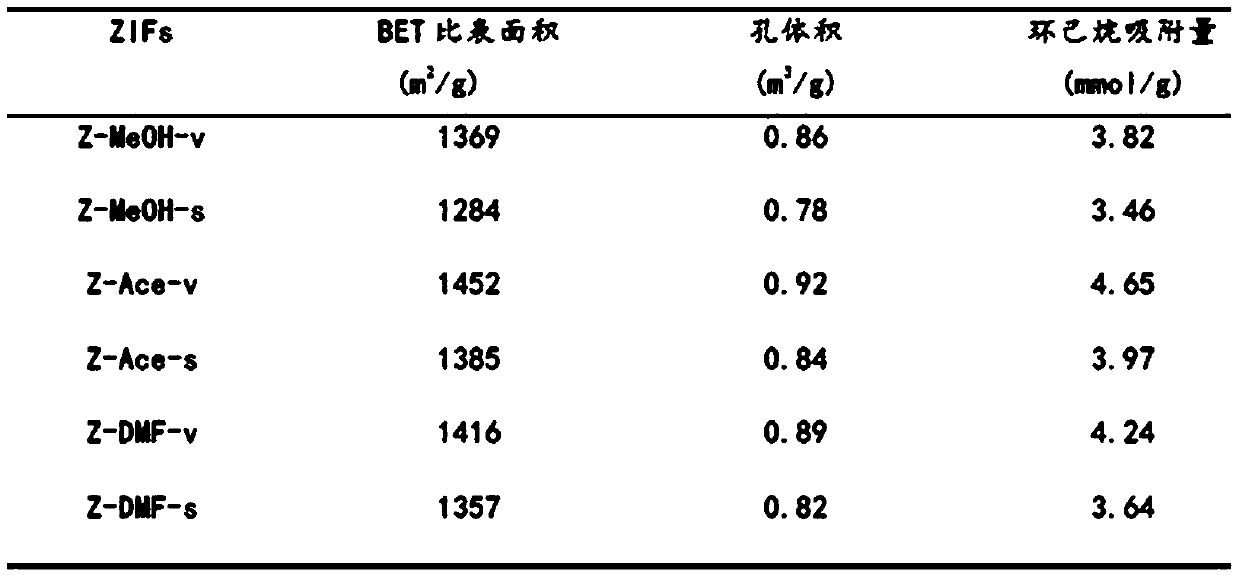

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com