Bioactive carbon source for sewage treatment and preparation method thereof

A biologically activated carbon and sewage treatment technology, applied in water/sludge/sewage treatment, special compound water treatment, anaerobic digestion treatment, etc., can solve problems such as high operating costs, hidden safety hazards, and large dosage, and achieve The effect of reducing operating costs, less dosage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

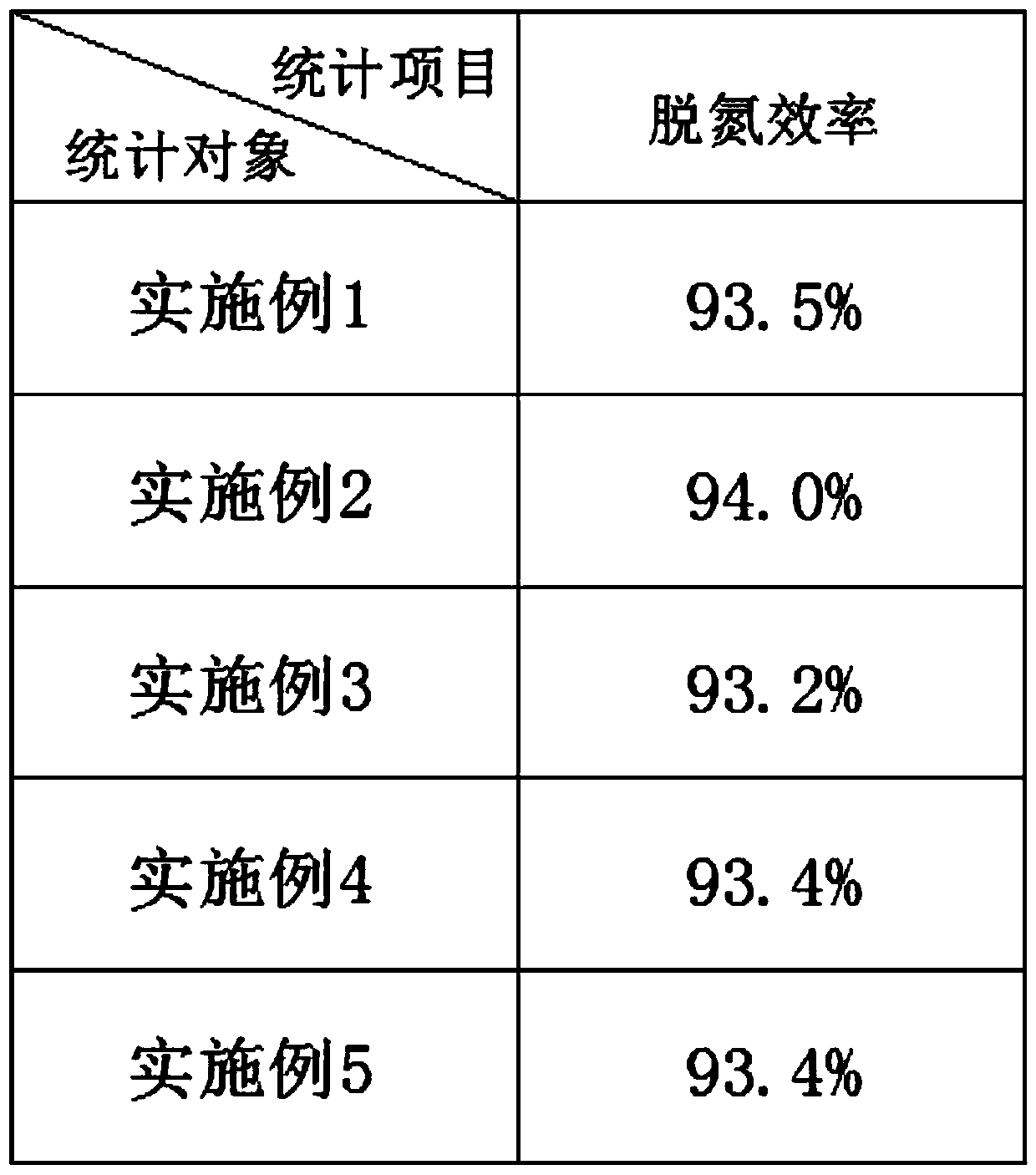

Examples

Embodiment 1

[0025] The raw materials include by weight: 31 parts of polyols, 20 parts of chitin, 1 part of vitamins, 6 parts of glucose, 20 parts of crude glycerin, 2 parts of bacterial strains and 20 parts of deionized water.

[0026] The invention also discloses a method for preparing biologically active carbon sources for sewage treatment, which specifically includes the following steps:

[0027] S1. Mixing of raw materials: firstly weigh according to the ratio of raw materials, then pour polyol and deionized water into the mixing container for mixing, after mixing fully, add chitin and vitamins in turn, and stir with a stirring rod;

[0028] S2, water bath heating: heat the mixing container in S1 in a water bath, control the heating device at a temperature of 40°C to heat evenly, and continue to add glucose, crude glycerin, and strain raw materials, and then continue to heat and stir with a stirring rod, and the duration for 2h;

[0029] S3. Cooling and sealing: Take out the mixing c...

Embodiment 2

[0031] The raw materials include by weight: 32 parts of polyols, 15 parts of chitin, 1.5 parts of vitamins, 5 parts of glucose, 21 parts of crude glycerin, 3 parts of strains and 22.5 parts of deionized water.

[0032] The invention also discloses a method for preparing biologically active carbon sources for sewage treatment, which specifically includes the following steps:

[0033] S1. Mixing of raw materials: firstly weigh according to the ratio of raw materials, then pour polyol and deionized water into the mixing container for mixing, after mixing fully, add chitin and vitamins in turn, and stir with a stirring rod;

[0034] S2, water bath heating: heat the mixing container in S1 in a water bath, control the heating device at a temperature of 40°C to heat evenly, and continue to add glucose, crude glycerin, and strain raw materials, and then continue to heat and stir with a stirring rod, and the duration for 2h;

[0035] S3. Cooling and sealing: Take out the mixing contai...

Embodiment 3

[0037] The raw materials include by weight: 33 parts of polyols, 12 parts of chitin, 0.5 parts of vitamins, 4 parts of glucose, 22 parts of crude glycerin, 5 parts of strains and 23.5 parts of deionized water.

[0038] The invention also discloses a method for preparing biologically active carbon sources for sewage treatment, which specifically includes the following steps:

[0039] S1. Mixing of raw materials: firstly weigh according to the ratio of raw materials, then pour polyol and deionized water into the mixing container for mixing, after mixing fully, add chitin and vitamins in turn, and stir with a stirring rod;

[0040] S2, water bath heating: heat the mixing container in S1 in a water bath, control the heating device at a temperature of 40°C to heat evenly, and continue to add glucose, crude glycerin, and strain raw materials, and then continue to heat and stir with a stirring rod, and the duration for 2h;

[0041] S3. Cooling and sealing: Take out the mixing contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com