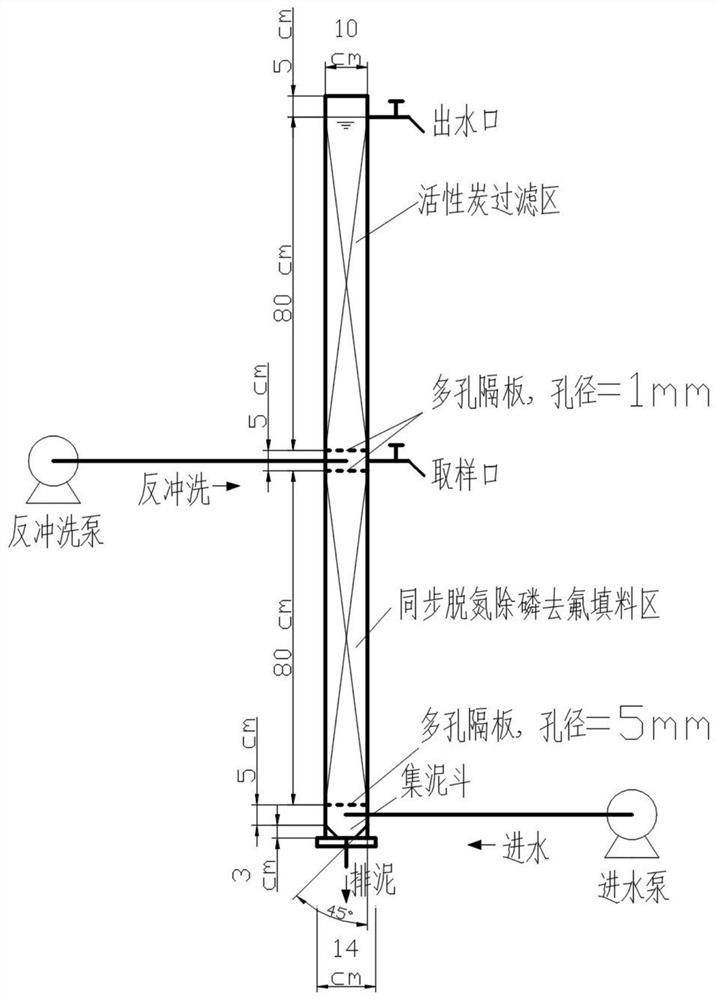

Catalytic particle carrier capable of synchronously removing nitrogen, phosphorus and fluorine and preparation method of catalytic particle carrier

A simultaneous denitrification and dephosphorization, particle technology, applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of low fluorine removal efficiency, complicated treatment process, increased treatment cost, etc. Fluorine efficiency, improved denitrification efficiency, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The raw materials of the simultaneous denitrification, dephosphorization and defluorination catalytic particle carrier are powdered activated carbon, zero-valent iron powder, an additive composed of palygorskite, activated alumina and polyaluminium chloride, and composed of zero-valent copper, zero-valent titanium and zero-valent The catalyst is composed of cobalt valence, and the binder is composed of water glass and phenolic resin.

[0047] One of the ingredients of the simultaneous denitrification, dephosphorization and defluorination catalyst particle carrier is powdered activated carbon: zero-valent iron powder: additive: catalyst: binder = 45%: 35%: 12.5%: 2.5%: 5%. Its preparation specific method comprises:

[0048] Step 1, preparation additive (with palygorskite: polyaluminum chloride: activated alumina=90%: 2%: 8%), catalyst (zero-valent copper: zero-valent titanium: zero-valent cobalt=85%: 2.5%: 12.5%) and binder (water glass: phenolic resin=85%: 15%).

[00...

Embodiment 2

[0062] The raw materials of the simultaneous denitrification, dephosphorization and defluorination catalytic particle carrier are powdered activated carbon, zero-valent iron powder, an additive composed of palygorskite, activated alumina and polyaluminium chloride, and composed of zero-valent copper, zero-valent titanium and zero-valent The catalyst is composed of cobalt valence, and the binder is composed of water glass and phenolic resin.

[0063] One of the ingredients of the simultaneous denitrification, phosphorus and defluorination catalytic particle carrier is powdered activated carbon: zero-valent iron powder: additive: catalyst: binder = 45%: 37.5%: 10%: 2.5%: 5%. Its preparation specific method comprises:

[0064] Step 1, preparation additive (with palygorskite: polyaluminum chloride: activated alumina=90%: 2%: 8%), catalyst (zero-valent copper: zero-valent titanium: zero-valent cobalt=85%: 2.5%: 12.5%) and binder (water glass: phenolic resin=85%: 15%).

[0065] St...

Embodiment 3

[0077] The raw materials of the simultaneous denitrification, dephosphorization and defluorination catalytic particle carrier are powdered activated carbon, zero-valent iron powder, an additive composed of palygorskite, activated alumina and polyaluminium chloride, and composed of zero-valent copper, zero-valent titanium and zero-valent The catalyst is composed of cobalt valence, and the binder is composed of water glass and phenolic resin.

[0078] One of the ingredients of the simultaneous denitrification, dephosphorization and defluorination catalytic particle carrier is powdered activated carbon: zero-valent iron powder: additive: catalyst: binder = 45%: 30%: 15%: 5%: 5%. Its preparation specific method comprises:

[0079] Step 1, preparation additive (with palygorskite: polyaluminum chloride: activated alumina=90%: 2%: 8%), catalyst (zero-valent copper: zero-valent titanium: zero-valent cobalt=85%: 2.5%: 12.5%) and binder (water glass: phenolic resin=85%: 15%).

[0080]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com