Process for treating aquaculture wastewater with high ammonia nitrogen and low carbon nitrogen ratio

A low-carbon nitrogen ratio, aquaculture wastewater technology, applied in animal husbandry wastewater treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

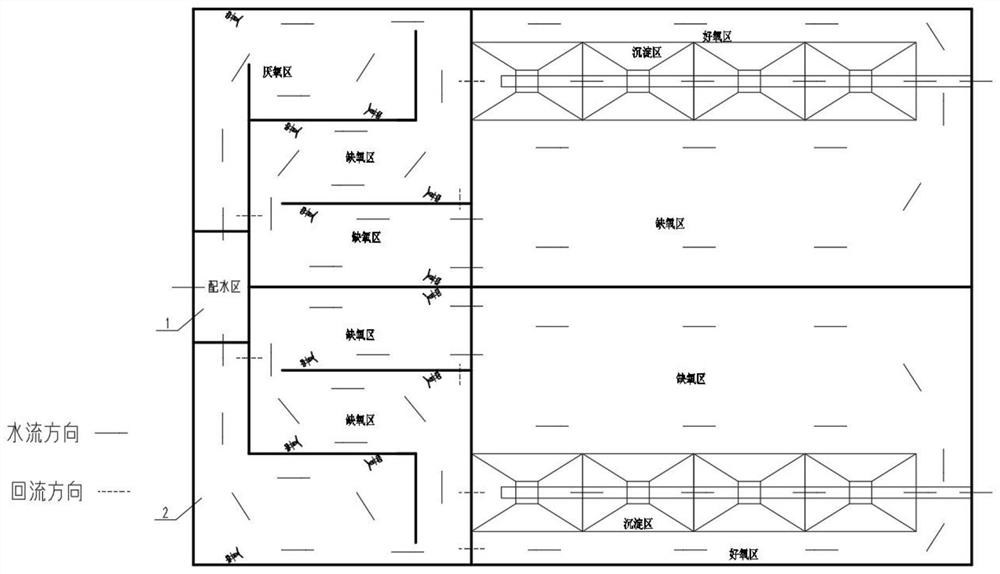

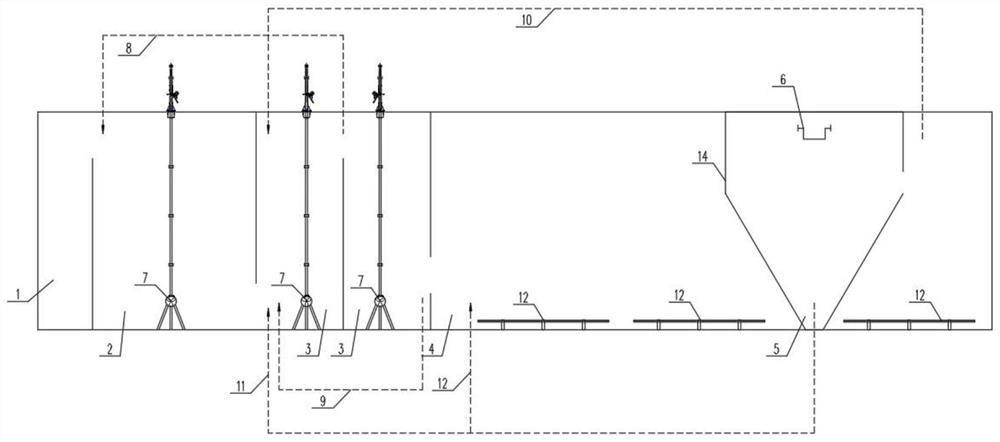

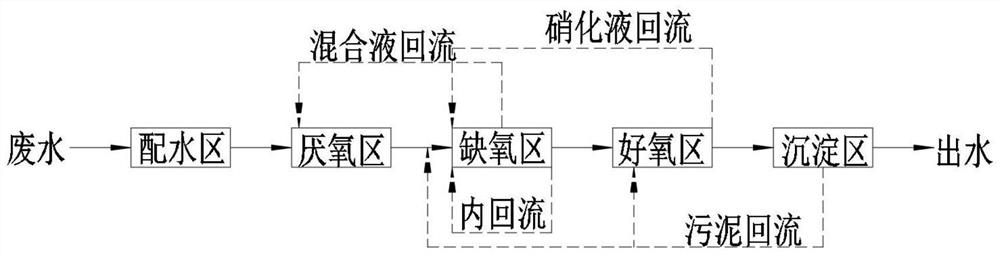

[0032] Embodiment one, such as Figure 1-3 As shown, a process for treating aquaculture wastewater with high ammonia nitrogen and low carbon-to-nitrogen ratio, the treatment system module of the process includes a water distribution area 1, and the water distribution area 1 is fixedly connected with two treatment systems, and the treatment system includes a fixed connection with the water distribution area 2 Anaerobic zone 2, anaerobic zone 2 is fixedly connected with anoxic zone 3, anoxic zone 3 is fixedly connected with aerobic zone 4, aerobic zone 4 is fixed with multiple sedimentation zones 5 inside, and sedimentation zone 5 is connected with the water outlet system 6 is fixedly connected, the sedimentation zone 5 also includes a combined sedimentation system 13, the combined sedimentation system 13 is used for mud-water separation, and the separated water is discharged to the subsequent advanced treatment through the water outlet system 6, the anaerobic zone 2 and the anox...

Embodiment 2

[0033] Embodiment 2, a treatment process also includes a multi-stage reflux system, the reflux system includes a mixed liquid reflux system 8, a reflux system 9 in the anoxic zone, a nitrifying liquid reflux system 10, a first sludge reflux system 11, and a second sludge reflux system System 12, the mixed liquid return system 8 is arranged between the anoxic zone 3 and the anaerobic zone 2, the mixed liquid return system 8 is used for the anoxic zone 3 to return the mixed liquid to the anaerobic zone 2, adopts the form of stripping, and can be used according to the water quality Adjust the return flow according to the situation, and the return flow system 9 in the anoxic zone is set between the two anoxic zones 3, and is used to obtain the internal return return liquid between the two anoxic zones 3. It adopts the stripping form, and the return flow can be adjusted according to the water quality. Flow rate, the nitrifying liquid return system 10 is set between the aerobic zone ...

Embodiment 3

[0034] Embodiment three, a kind of process of processing the culture waste water of high ammonia nitrogen low carbon nitrogen ratio, its process step is:

[0035] S101: Wastewater enters the water distribution area for water distribution treatment. One stream of waste water is divided into two streams to the subsequent treatment stage. When the water volume is only 50%-60% of the designed water volume, water can be distributed to one side only to reduce operating costs;

[0036] S102: The two streams of wastewater enter the two anaerobic zones respectively. The wastewater uses the action of anaerobic bacteria in this zone to decompose macromolecular organic matter into small molecular organic matter, which is usually called the hydrolysis and acidification stage. The mixed solution returned by the reflux system, the phosphobacteria will release phosphorus at this stage;

[0037] S103: Form a facultative and anoxic environment through the dissolved oxygen carried in the reflux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com