A kind of lactitol production process

A production process and lactitol technology, applied in the production process field of functional sugar alcohol, can solve problems such as complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

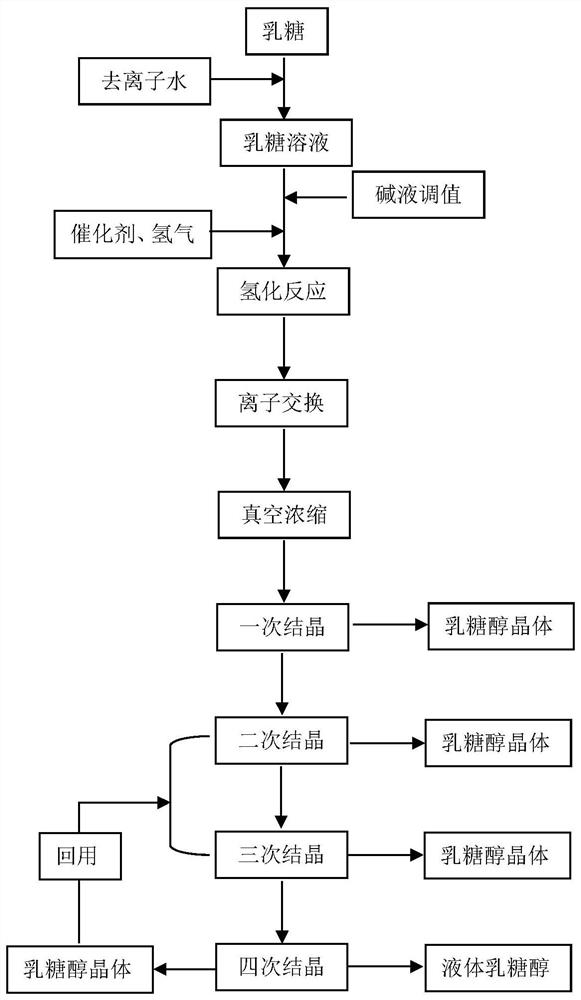

Image

Examples

Embodiment 1

[0035] Add 12000.0 grams of lactose into deionized water to form a lactose solution with a concentration of 25.0% by mass, with a purity of 99.0%, adjust the pH to 8.0, add a ruthenium carbon catalyst with 2% lactose mass, set the hydrogenation temperature to 110°C, and the hydrogen pressure to 8.0 MPa, reacted for 3.0 hours to obtain a lactose hydrogenation solution, filtered to remove the catalyst to obtain a lactitol solution, collected the catalyst and reused it, the index of the lactitol solution was: mass percentage concentration 26.5%, lactitol purity 92.9%, lactose residual 4.8% , Conductivity 186.0μs / cm, transmittance 95.0%.

[0036] Ion-exchange the lactitol solution through a mixed bed at a speed of 2BV to obtain a lactitol purification solution, the indicators are: mass percentage concentration 23.0%, lactitol purity 93.5%, electrical conductivity 10.5μs / cm, and light transmission 99.9%.

[0037] Primary crystallization: the lactitol solution is concentrated to a m...

Embodiment 2

[0043] Add 12000.0 grams of lactose into deionized water to make a lactose solution with a mass percentage concentration of 45.0%, adjust the pH to 8.5, add a ruthenium carbon catalyst with 8% lactose mass, set the hydrogenation temperature to 120°C, hydrogen pressure to 10.0MPa, and react at 2.0 h, to obtain a lactose hydrogenation solution, filter and remove the catalyst to obtain a lactitol solution, collect the catalyst and reuse it, the index of the lactitol solution is: mass percentage concentration 48.0%, lactitol purity 98.7%, lactose residual 0.1%, electrical conductivity 123.0 μs / cm, transmittance 99.0%.

[0044] The lactitol solution was ion-exchanged through the mixed bed at a speed of 4BV to obtain a lactitol purification solution. The indicators were: mass percentage concentration 41.0%, lactitol purity 99.1%, electrical conductivity 4.68 μs / cm, and light transmission 100%.

[0045] Primary crystallization: the lactitol solution is concentrated to a mass percenta...

Embodiment 3

[0050] Add 12000.0 grams of lactose into deionized water to form a lactose solution with a concentration of 40.0% by mass, adjust the pH to 9.5, add a Raney nickel catalyst with 6% lactose mass, set the hydrogenation temperature to 115°C, and the hydrogen pressure to 9.0MPa. After 1.5 hours, the lactose hydrogenation solution was obtained, and the catalyst was removed by filtration after sedimentation to obtain a lactitol solution. The catalyst was collected and reused. The indicators of the lactitol solution were: mass percentage concentration 43.0%, lactitol purity 98.5%, electrical conductivity 126.0μs / cm, light transmittance 98.9%.

[0051] The lactitol solution was ion-exchanged through the mixed bed at a speed of 3BV to obtain a lactitol purification solution. The indicators were: mass percentage concentration of 38.0%, lactitol purity of 99.1%, electrical conductivity of 5.3μs / cm, and light transmission of 100%.

[0052] Primary crystallization: the lactitol solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com