Polyphenyl ether/high impact polystyrene composition and preparation method thereof

A technology of polystyrene and polystyrene resin, applied in the field of materials, can solve the problems of difficulty in obtaining processability and mechanical properties of PPO/HIPS composition, high glass transition temperature of pure PPO resin, and limited application range, etc. Color stability and melt stability, low equipment requirements, and the effect of improving dyeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

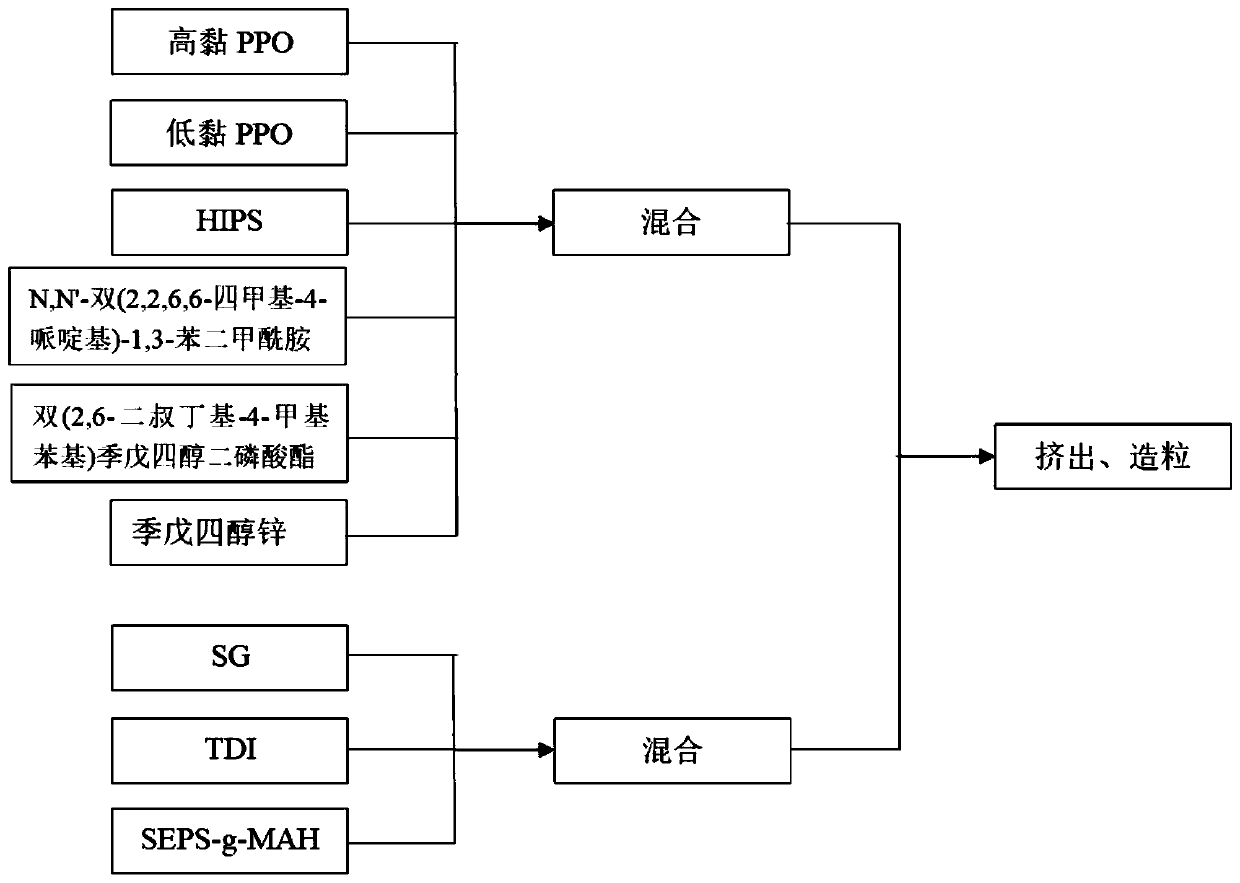

Method used

Image

Examples

Embodiment 1

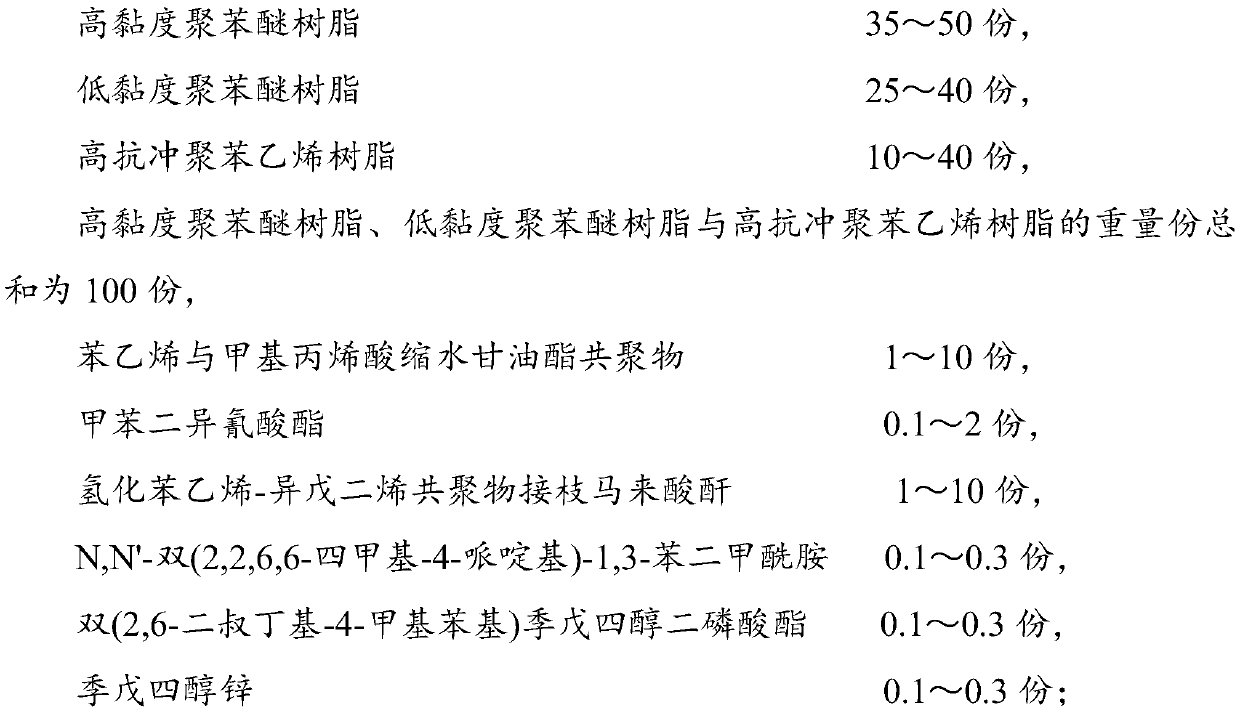

[0069] In this embodiment, a polyphenylene ether / high-impact polystyrene composition is prepared from the following raw materials in parts by weight:

[0070] High viscosity polyphenylene ether resin (intrinsic viscosity 0.48dL / g) 35 parts,

[0071] Low viscosity polyphenylene ether resin (intrinsic viscosity 0.35dL / g) 25 parts,

[0072] High impact polystyrene resin (number average molecular weight is 23000) 40 parts,

[0073] The sum of parts by weight of high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin and high-impact polystyrene resin is 100 parts,

[0074]

[0075] The preparation method of the above-mentioned polyphenylene ether / high-impact polystyrene composition comprises the following steps:

[0076] (1) Dry the high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin and high-impact polystyrene resin at a temperature of 80°C for 8 hours, then cool, and the cooled high-viscosity polyphenylene ether resin,...

Embodiment 2

[0081] In this embodiment, a polyphenylene ether / high-impact polystyrene composition is prepared from the following raw materials in parts by weight:

[0082] High viscosity polyphenylene ether resin (intrinsic viscosity 0.48dL / g) 50 parts,

[0083] 40 parts of low viscosity polyphenylene ether resin (intrinsic viscosity 0.35dL / g),

[0084] 10 parts of high-impact polystyrene resin (number average molecular weight is 23000),

[0085] The sum of parts by weight of high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin and high-impact polystyrene resin is 100 parts,

[0086]

[0087] The preparation method of the above-mentioned polyphenylene ether / high-impact polystyrene composition comprises the following steps:

[0088](1) Dry the high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin and high-impact polystyrene resin at a temperature of 110°C for 4 hours, then cool, and the cooled high-viscosity polyphenylene ether ...

Embodiment 3

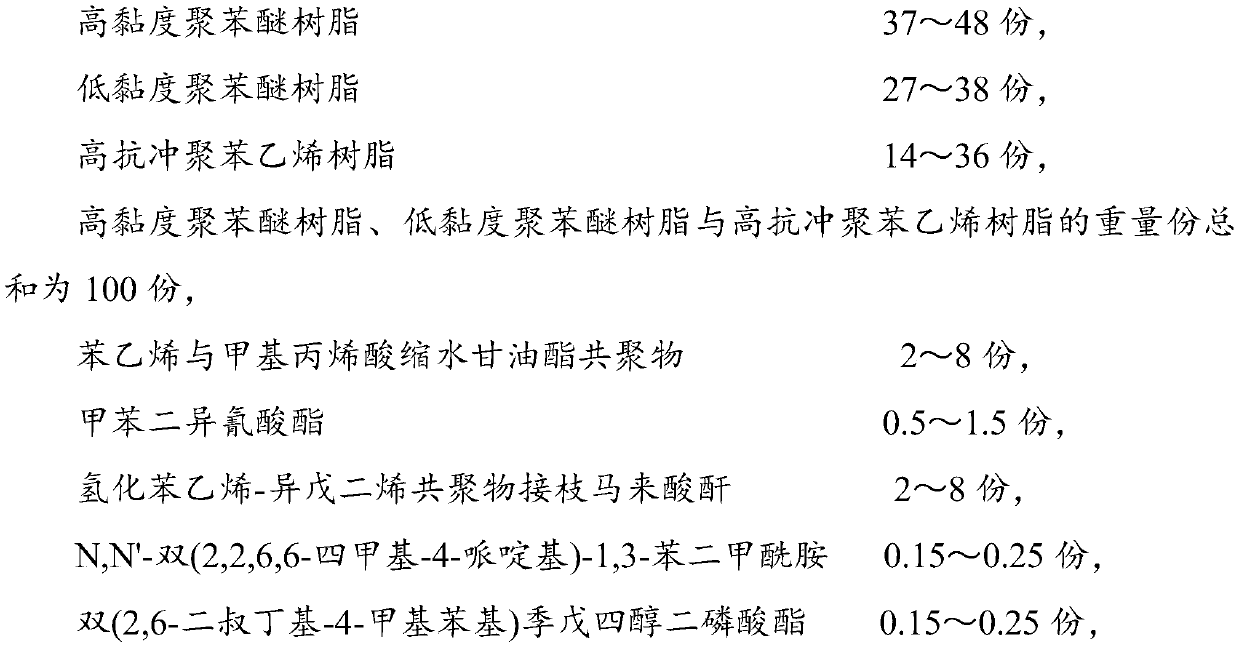

[0093] In this embodiment, a polyphenylene ether / high-impact polystyrene composition is prepared from the following raw materials in parts by weight:

[0094] High viscosity polyphenylene ether resin (intrinsic viscosity 0.48dL / g) 37 parts,

[0095] Low-viscosity polyphenylene ether resin (intrinsic viscosity 0.35dL / g) 27 parts,

[0096] 36 parts of high-impact polystyrene resin (number average molecular weight is 23000),

[0097] The sum of parts by weight of high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin and high-impact polystyrene resin is 100 parts,

[0098]

[0099]

[0100] The preparation method of the above-mentioned polyphenylene ether / high-impact polystyrene composition comprises the following steps:

[0101] (1) After drying the high-viscosity polyphenylene ether resin, low-viscosity polyphenylene ether resin and high-impact polystyrene resin at a temperature of 90°C for 6 hours, cooling, the cooled high-viscosity polypheny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com