Porous carbon-based shaped composite phase-change material, preparation and application

A composite phase change material and phase change material technology, which is applied in the field of preparation of porous carbon-based shaped composite phase change materials, can solve problems such as leakage, flow, and liquid state, and achieve simple raw materials, easy access to raw materials, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 1.5g of sucrose and 1.0g of sodium bicarbonate into a ball mill jar, and mill at a speed of 300r / min for 30min. The mixed product was ignited with 1.5mL ethanol, and the porous carbon precursor was obtained by burning; 2 Under the atmosphere, the temperature was raised to 800° C., and the temperature was kept constant for 3 hours to obtain porous carbon.

[0027] (2) Add an appropriate amount of paraffin to the product in (1), put it in a vacuum oven, set the temperature at 80°C, and soak for 2 hours.

[0028] (3) Put the product obtained in (2) into an oven to remove unimpregnated paraffin, and finally obtain a porous carbon-based shaped composite phase change material.

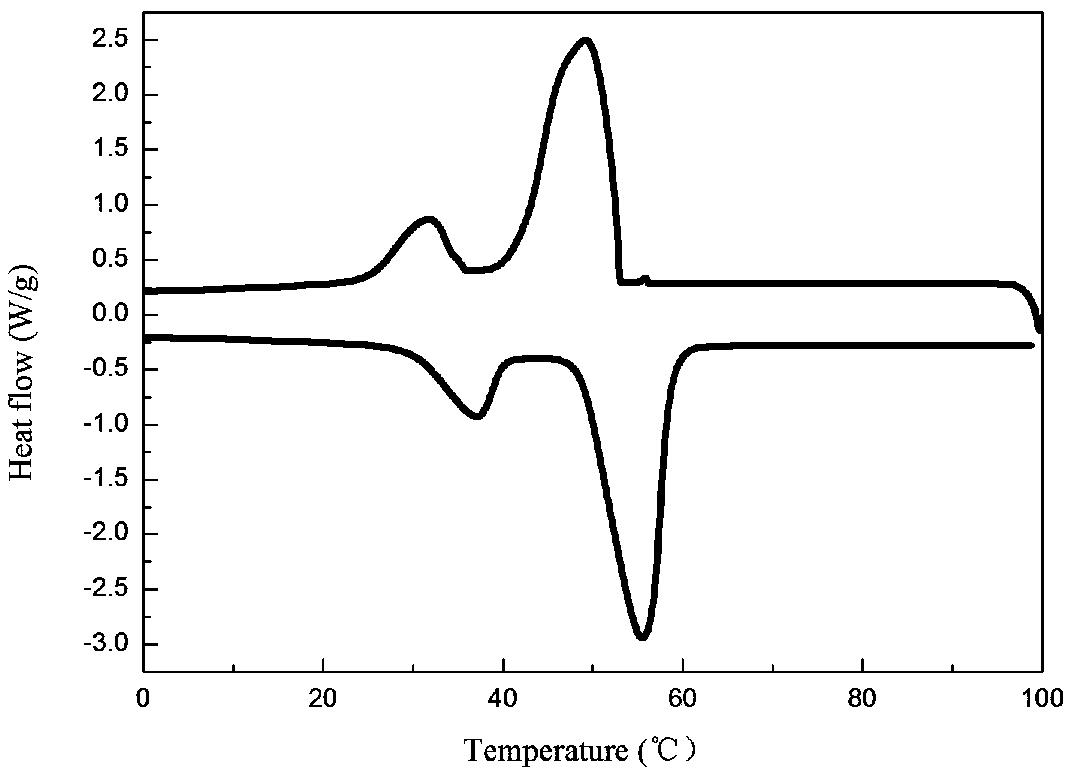

[0029] The porous carbon-based shaped composite phase change material of the present invention is a black lump, wherein the mass percentage of paraffin wax accounts for about 75%, and its differential scanning calorimetry curve is as follows: figure 1 shown. In the process of preparing the...

Embodiment 2

[0031] (1) Take 1.5g of sucrose and 1.5g of sodium bicarbonate into a ball mill jar, and mill at a speed of 300r / min for 30min. The mixed product was ignited with 2mL ethanol, and the porous carbon precursor was obtained by burning; 2 Under the atmosphere, the temperature was raised to 800° C., and the temperature was kept constant for 3 hours to obtain porous carbon.

[0032] (2) Add an appropriate amount of paraffin to the product in (1), put it in a vacuum oven, set the temperature at 80°C, and soak for 2 hours.

[0033] (3) Put the product obtained in (2) into an oven to remove unimpregnated paraffin, and finally obtain a porous carbon-based shaped composite phase change material.

[0034] The porous carbon-based shaped composite phase-change material of the present invention is a black lump, wherein the paraffin wax accounts for about 70% by mass. In the process of preparing the composite phase change material, the complicated process of preparing porous carbon template...

Embodiment 3

[0036] (1) Take 1.5g of sucrose and 1.0g of sodium bicarbonate into a ball mill jar, and mill at a speed of 300r / min for 30min. The mixed product was ignited with 1.5mL ethanol, and the porous carbon precursor was obtained by burning; 2 Under the atmosphere, the temperature was raised to 700° C., and the temperature was kept constant for 2 hours to obtain porous carbon.

[0037] (2) Add an appropriate amount of paraffin to the product in (1), put it in a vacuum oven, set the temperature at 80°C, and soak for 2 hours.

[0038] (3) Put the product obtained in (2) into an oven to remove unimpregnated paraffin, and finally obtain a porous carbon-based shaped composite phase change material.

[0039]The porous carbon-based shaped composite phase-change material of the present invention is a black lump, wherein the paraffin wax accounts for about 65% by mass. In the process of preparing the composite phase change material, the complicated process of preparing porous carbon templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com