Novel combustion device with nozzle slagging prevention function

A combustion device and nozzle technology, which is applied in the direction of burning with various fuels, burners, and burning with block fuels and liquid fuels, etc. It can solve the problems of large coal consumption, difficulty in ignition, high boiler shutdown rate, etc., and achieve reduction The frequency of downtime for maintenance, reducing the coking of the water wall of the furnace, and overcoming the serious effect of slagging at the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

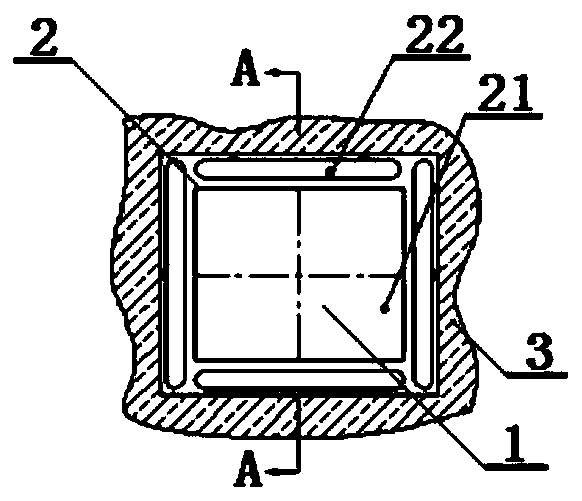

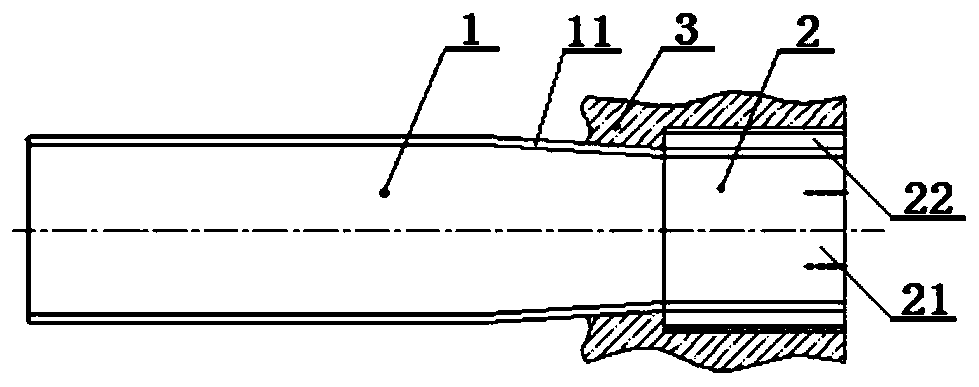

[0019] exist figure 1 and figure 2 Among them, a new type of combustion device with the function of preventing slagging at the spout according to the present invention mainly includes an air powder passage 1, an air powder nozzle 2 and a limit adhesive tape 3, and is characterized in that:

[0020] The air powder nozzle 2 has the functions of preventing slagging at the nozzle and ensuring smooth air injection, and includes the middle nozzle 21 and the peripheral high-speed wind nozzle 22 arranged on the periphery of the middle nozzle 21;

[0021] The position-limiting adhesive tape 3 has the functions of preventing adhesion and accumulation of ash on the surface of the adhesive tape, ensuring that the airflow ejected from the spout diffuses unhindered in the furnace cavity, and is arranged between the air powder spout 2 and the furnace wall by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com