High-sensitivity SPR refractive index sensor based on plastic optical fiber periodic narrow-groove structure

A technology of refractive index sensor and plastic optical fiber, which is applied in the direction of cladding optical fiber, microstructured optical fiber, instrument, etc., can solve the problems of high production cost, cumbersome and complicated process, and the inability of optical fiber SPR refractive index sensor to realize precise refractive index detection, etc., to achieve Low cost, increase the contact area, and ensure the effect of processing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

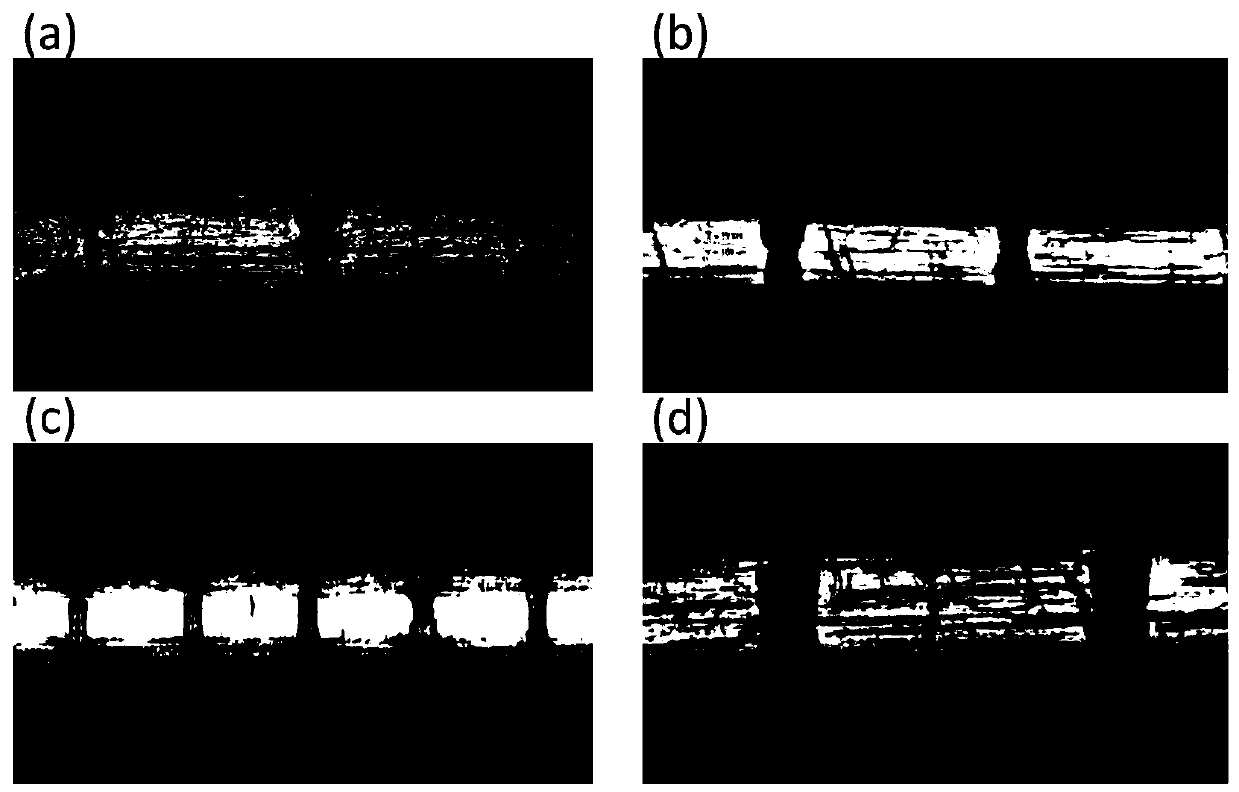

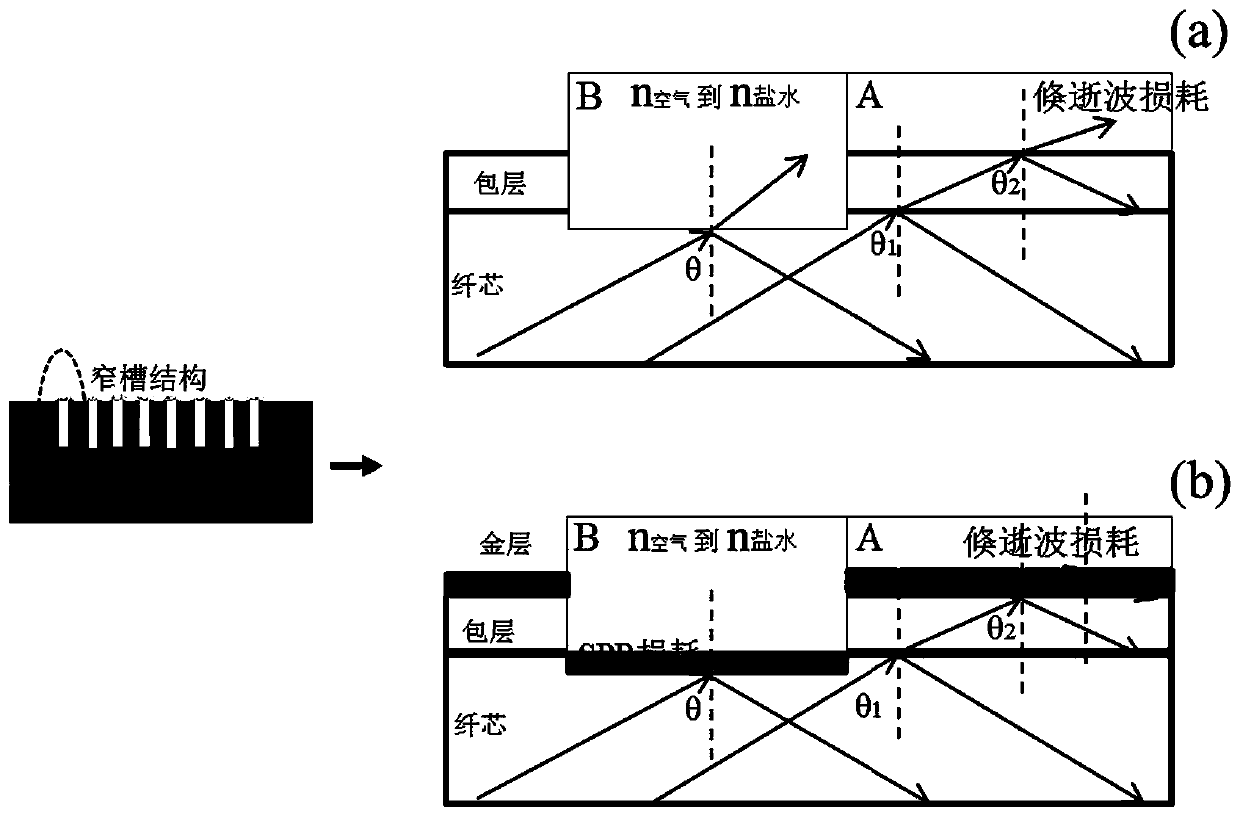

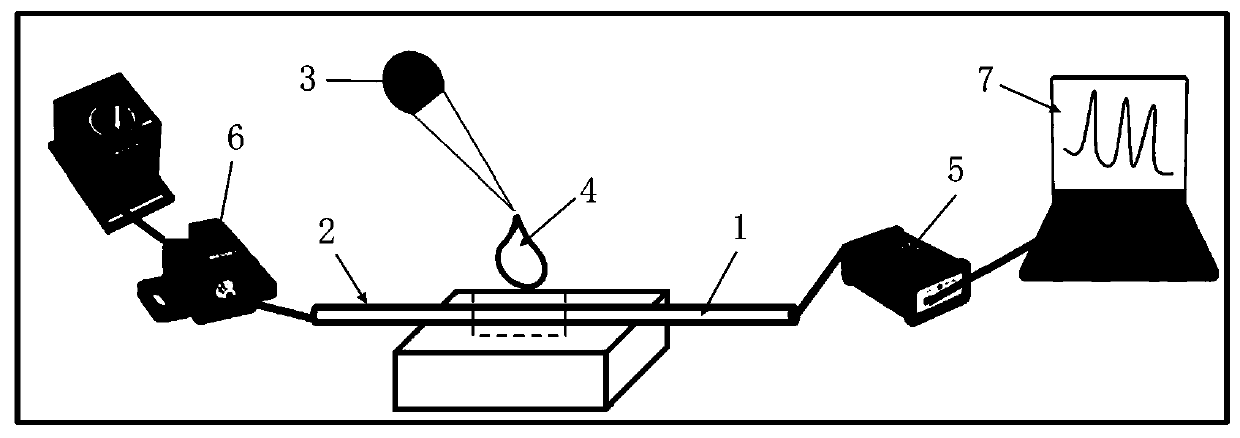

[0025] A high-sensitivity SPR refractive index sensor based on a plastic optical fiber periodic narrow groove structure, comprising a plastic optical fiber, a section of a certain length of the plastic optical fiber is provided with a row of periodic narrow groove structures along the axial direction, the The periodic narrow groove structure is an equidistant radial semicircular groove structure, the groove width of the radial semicircular groove structure is 5~20um, the groove depth is 20~100um, and the distance between adjacent radial semicircular groove structures is 400~900um, the surface of the plastic optical fiber is all coated with a layer of gold film. The length of a section of the plastic optical fiber with a periodic narrow groove structure is 0.5-1 cm.

[0026] The above-mentioned processing method of the high-sensitivity SPR refractive index sensor based on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com