Self-adjusting fuzzy Smith-PID temperature control system and method

A temperature control system and temperature control technology, applied in the direction of temperature control, general control system, control/regulation system, etc., can solve the problems of boiler heating surface corrosion, slag agglomeration, furnace blockage, combustion instability, etc., and achieve satisfactory control effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

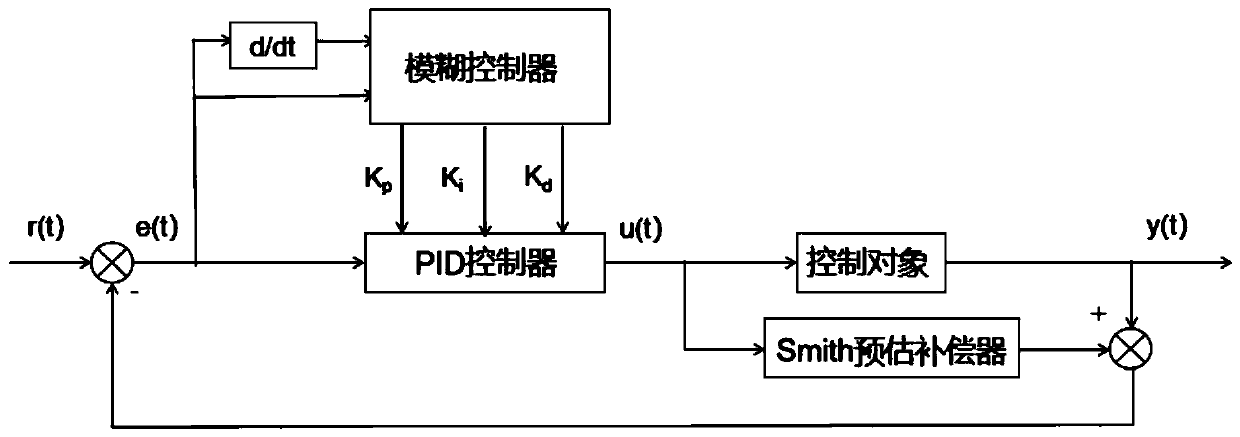

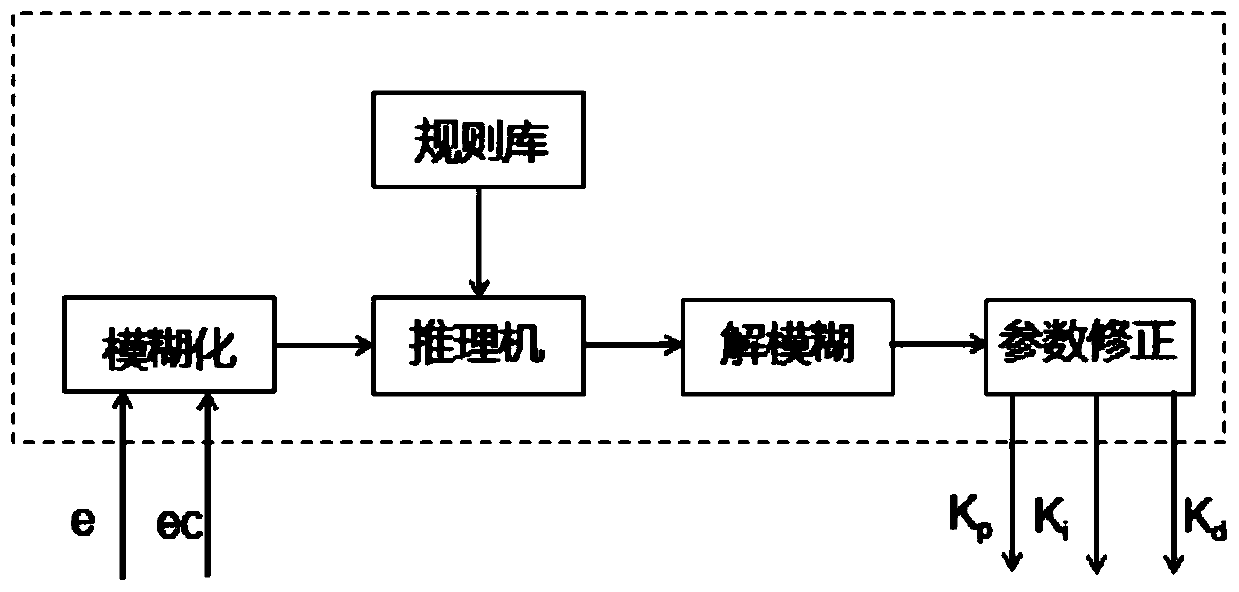

[0040] Such as figure 1 A kind of self-adjusting fuzzy Smith-PID temperature control system shown, comprises self-adjusting fuzzy Smith-PID controller, programmable logic controller (PLC), temperature control executive device and temperature sensor; Described self-adjusting fuzzy Smith-PID control The device is to introduce fuzzy controller and Simth predictive compensator in PID controller; Temperature sensor is connected with described self-adjusting fuzzy Smith-PID controller; Self-adjusting fuzzy Smith-PID controller is connected with programmable controller, programmable The PLC control unit of the controller controls the temperature control actuator.

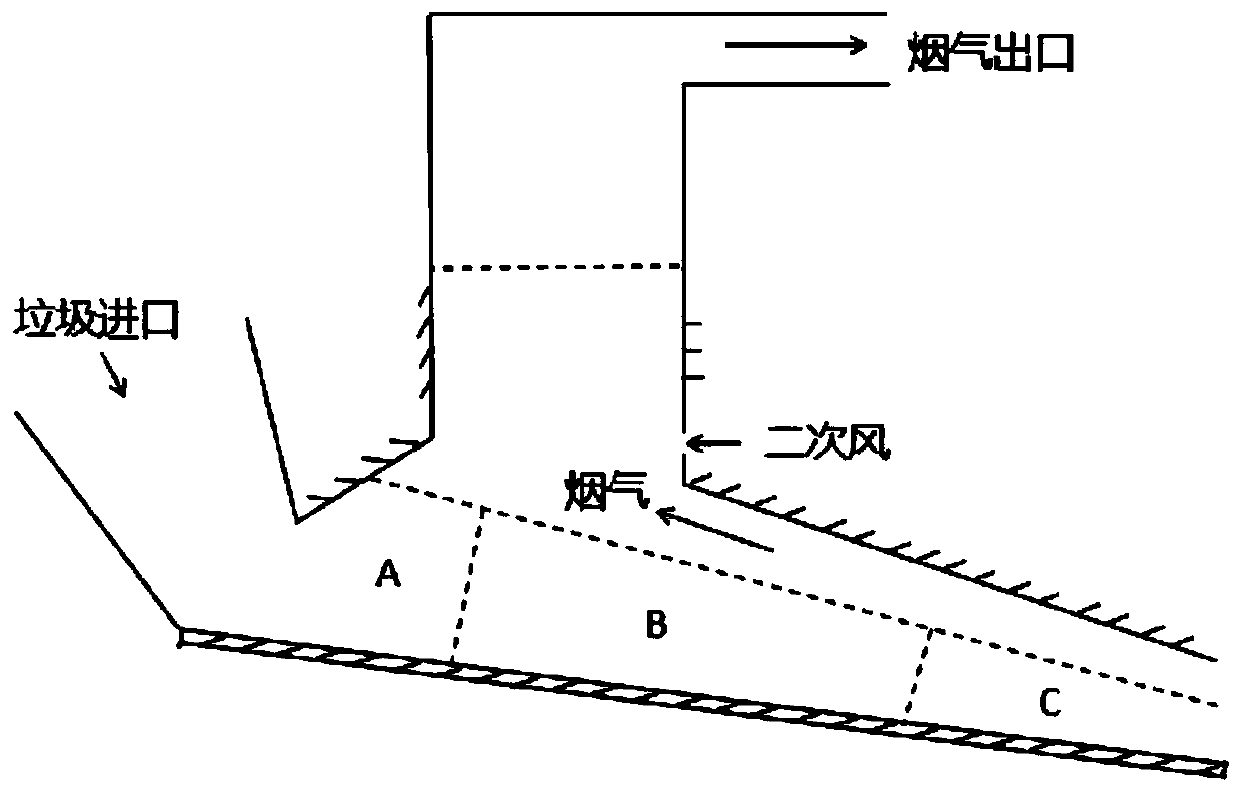

[0041] The system uses temperature sensors to measure the actual temperature of different areas in the waste inci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com