High-frequency micro-electric protection mutual inductor

A transformer and micro-electric technology, applied in the direction of inductors, transformer/inductor cores, transformer/inductor coils/windings/connections, etc., can solve transformer and circuit system damage, transformer electromagnetic noise and jitter, etc. problems, to achieve the effect of strong anti-electromagnetic interference, prevent electromagnetic noise and jitter, and shield interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

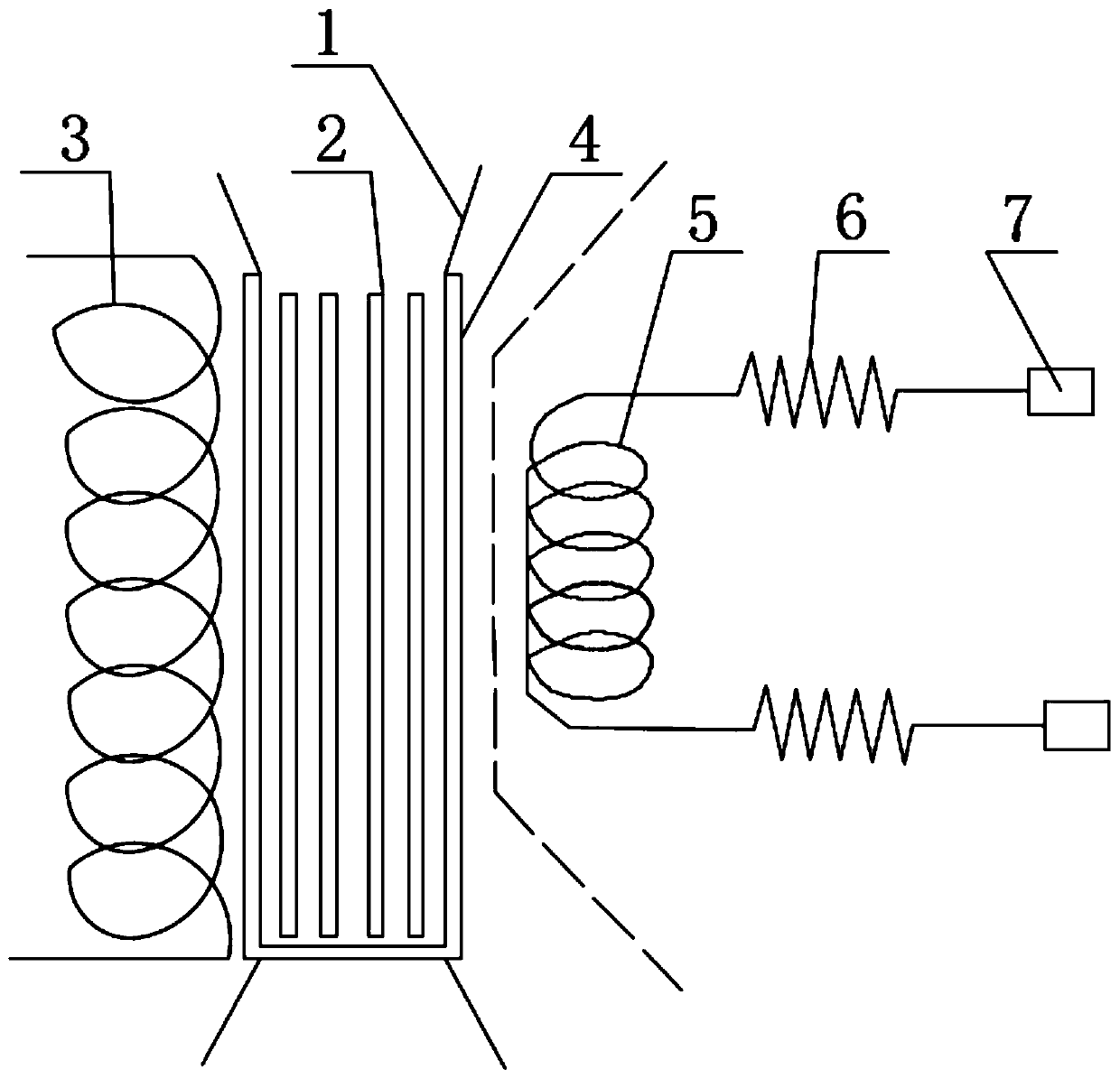

[0025] Such as figure 1 As shown, a high-frequency micro-current protection transformer of this embodiment includes a closed iron core 2 composed of two high-frequency ferrite soft magnetic cores, and the two cores are respectively provided with primary coils 5 and the secondary coil 3, each of the two leading ends of the primary coil 5 is connected in series with a high resistance resistor 6.

[0026] Both the primary coil 5 and the secondary coil 3 are wound with enamelled copper wires in multiple layers, and the number of winding turns is more than 4000 turns.

[0027] The enamelled copper wires used for the primary coil 5 and the secondary coil 3 are of the same specification, and the diameter is less than 0.1 mm. When leading the wires, the last turn is a three-strand wire lead.

[0028] The high resistance resistor 6 has a resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com