Preparation method of multi-transition metal nitride zinc-air battery cathode material

A technology of zinc nitride and cathode material is applied in battery electrodes, fuel cell type half cells and secondary battery type half cells, circuits, etc. Strong charge-discharge long-term cycle stability, rich pore structure, and anti-aggregation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) After dissolving 0.45g of guanidine carbonate in 30mL of deionized water, add 0.15g of Co(CH 3 COO) 2 ·6H 2 O, stirred at room temperature for 10min; subsequently, added 0.80g Zn(NO 3 ) 2 ·6H 2 O, and after stirring at room temperature for 30min, a transition metal salt solution was formed;

[0038] (2) Add 0.3 g of locust bean gum to the transition metal solution, and stir at room temperature for 3 hours to obtain a viscous liquid;

[0039](3) freeze-drying the viscous liquid obtained in step (2) at -85°C to obtain a spongy solid;

[0040] (4) Put the spongy solid in step (3) into a covered porcelain crucible and then put it into a tube furnace, then raise the temperature to 900°C at a heating rate of 5°C / min under an argon (Ar) atmosphere Argon (Ar), and kept at this temperature for 1.5h; to be naturally cooled to room temperature to obtain a black powder. Named Zn / CoN-NC.

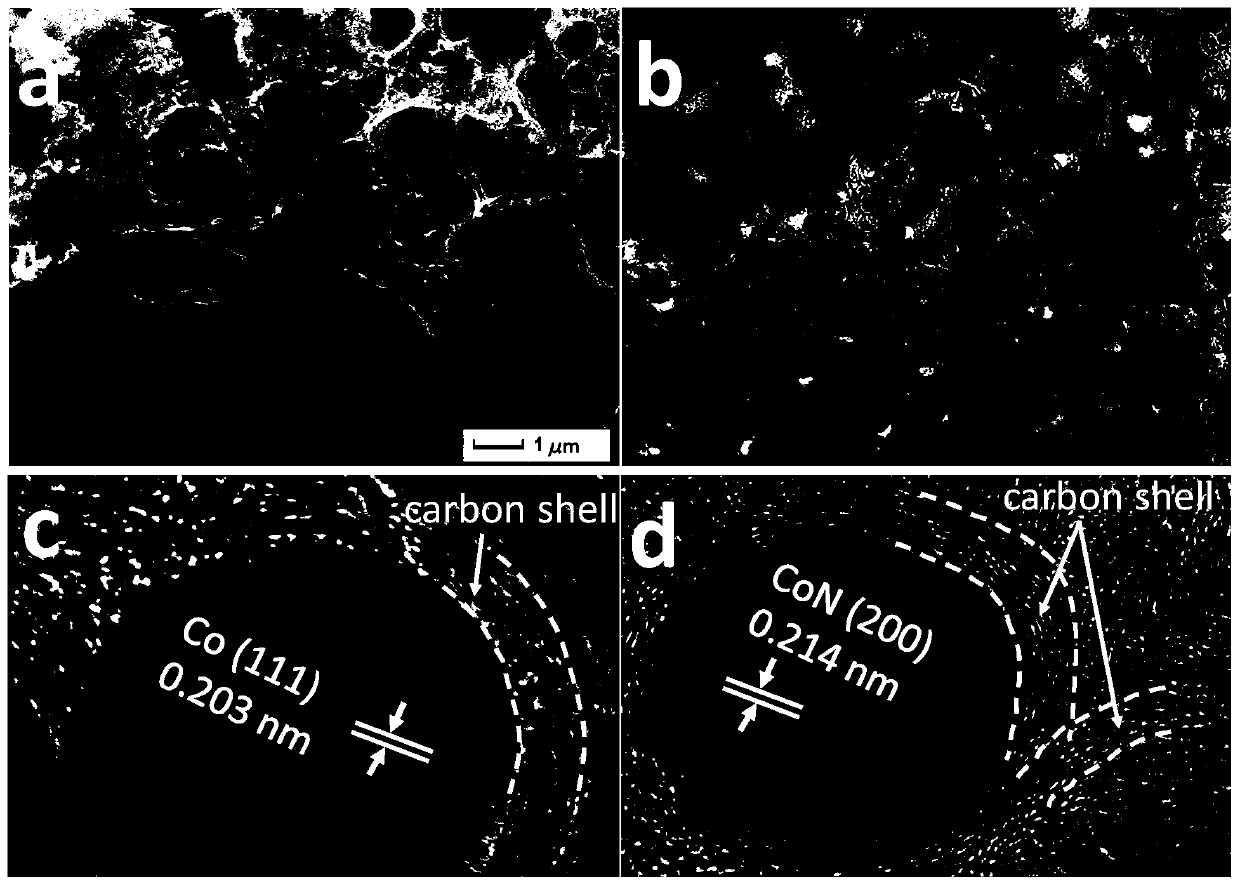

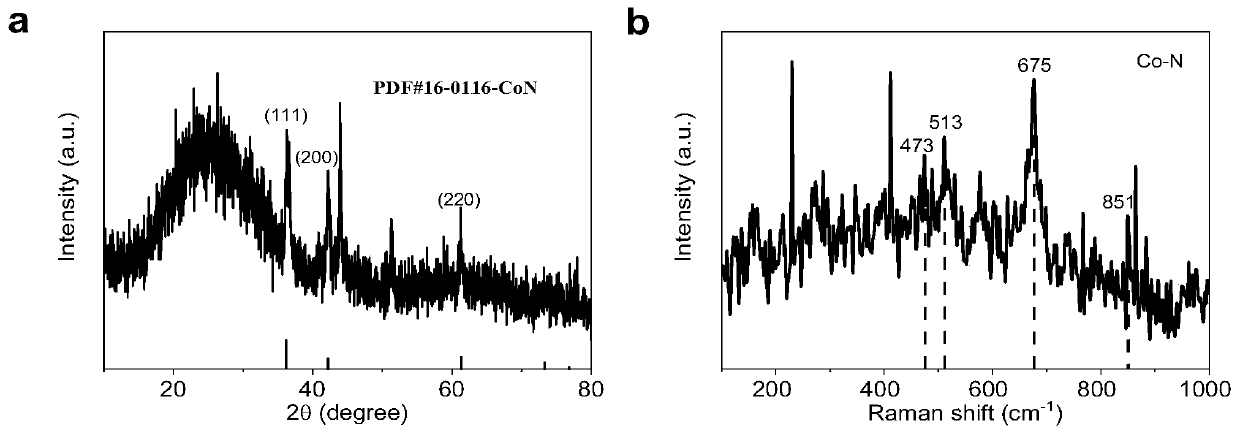

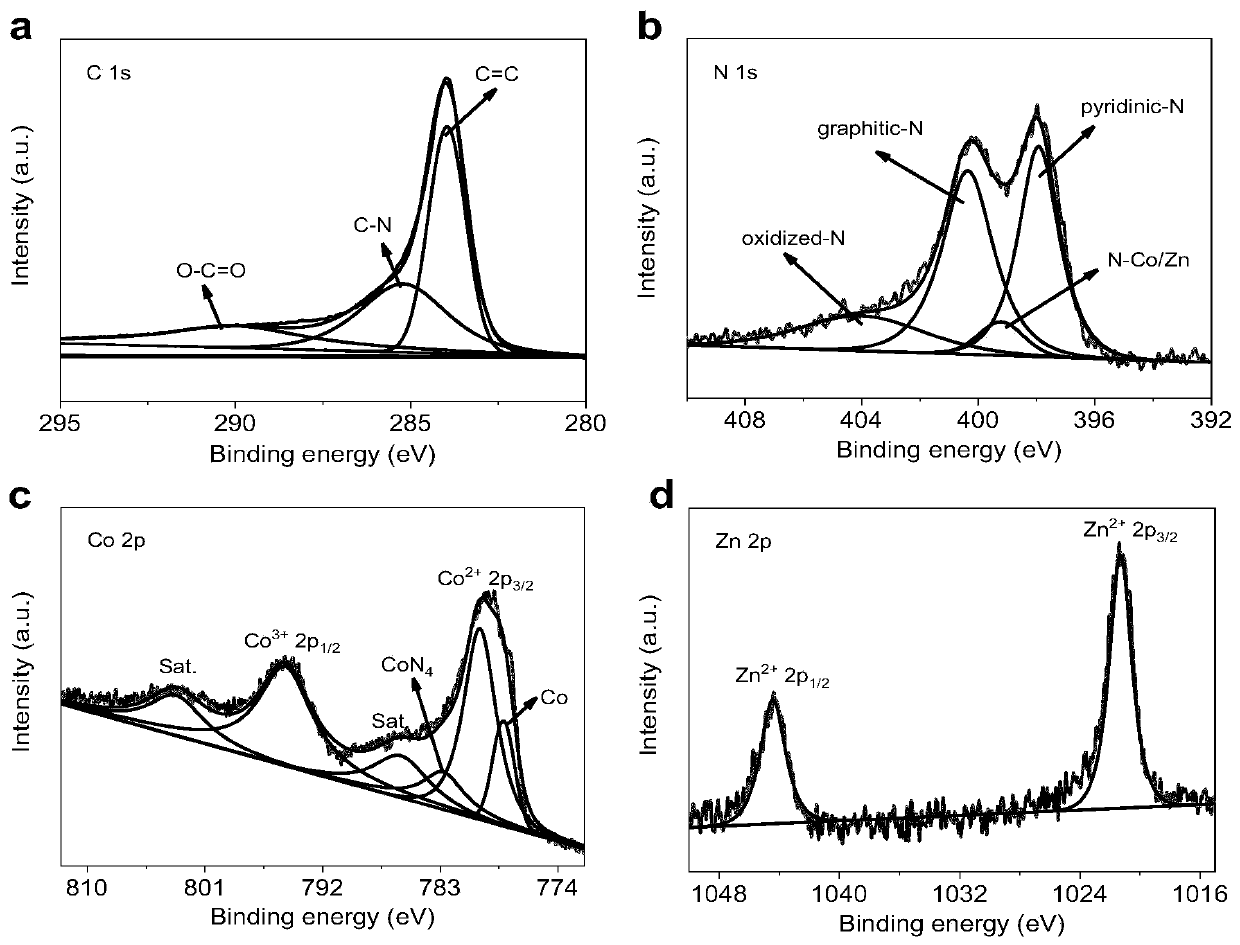

[0041] The final electrocatalysts obtained above were characterized by X-ray diffr...

Embodiment 2

[0043] (1) After dissolving 0.45g of guanidine carbonate in 30mL of deionized water, add 0.12g of MnCl 2 4H 2 O, stirred at room temperature for 10min; subsequently, added 0.80g Zn(NO 3 ) 2 ·6H 2 O, and after stirring at room temperature for 30min, a transition metal salt solution was formed;

[0044] (2) Add 0.3 g of locust bean gum to the transition metal solution, and stir at room temperature for 3 hours to obtain a viscous liquid;

[0045] (3) freeze-drying the viscous liquid obtained in step (2) at -85°C to obtain a spongy solid;

[0046] (4) Put the spongy solid in step (3) into a covered porcelain crucible and then put it into a tube furnace, then raise the temperature to 900°C at a heating rate of 5°C / min under an argon (Ar) atmosphere Argon (Ar), and kept at this temperature for 1.5h; to be naturally cooled to room temperature to obtain a black powder. Named Zn / MnNC.

[0047] The final electrocatalysts obtained above were characterized by X-ray diffraction (XRD...

Embodiment 3

[0049] (1) After dissolving 0.45g of guanidine carbonate in 30mL of deionized water, add 0.80g of Zn(NO 3 ) 2 ·6H 2 O, and stirred at room temperature for 10 min; subsequently, 0.034 g of CuCl was added to the above aqueous solution 2 2H 2 O forms a transition metal salt solution;

[0050] (2) Add 0.3 g of locust bean gum to the transition metal solution, and stir at room temperature for 3 hours to obtain a viscous liquid;

[0051] (3) freeze-drying the viscous liquid obtained in step (2) at -85°C to obtain a spongy solid;

[0052] (4) Put the spongy solid in step (3) into a covered porcelain crucible and then put it into a tube furnace, then raise the temperature to 900°C at a heating rate of 5°C / min under an argon (Ar) atmosphere Argon (Ar), and kept at this temperature for 1.5h; to be naturally cooled to room temperature to obtain a black powder. Named Zn / CuNC.

[0053] The final electrocatalysts obtained above were characterized by X-ray diffraction (XRD), scanning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com