A method for improving the mineral phase structure of sintered ore

A technology of sinter and mineral phase, which can be applied to improve the mineral phase structure of sinter and the field of sintering, and can solve the problems of reducing the strength and quality of sinter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

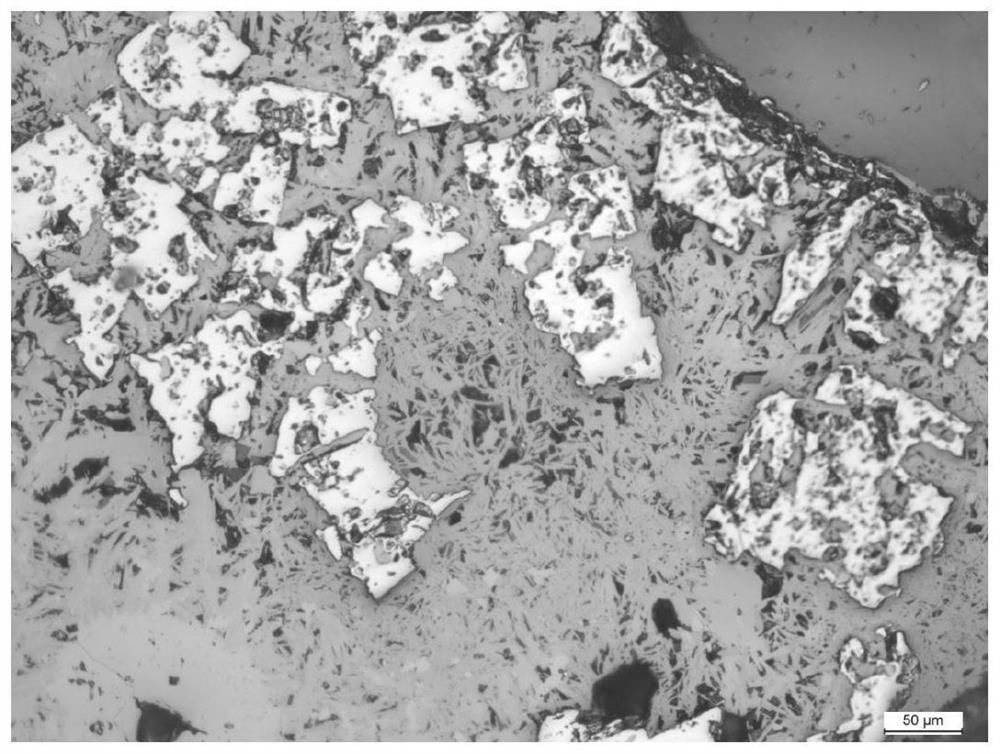

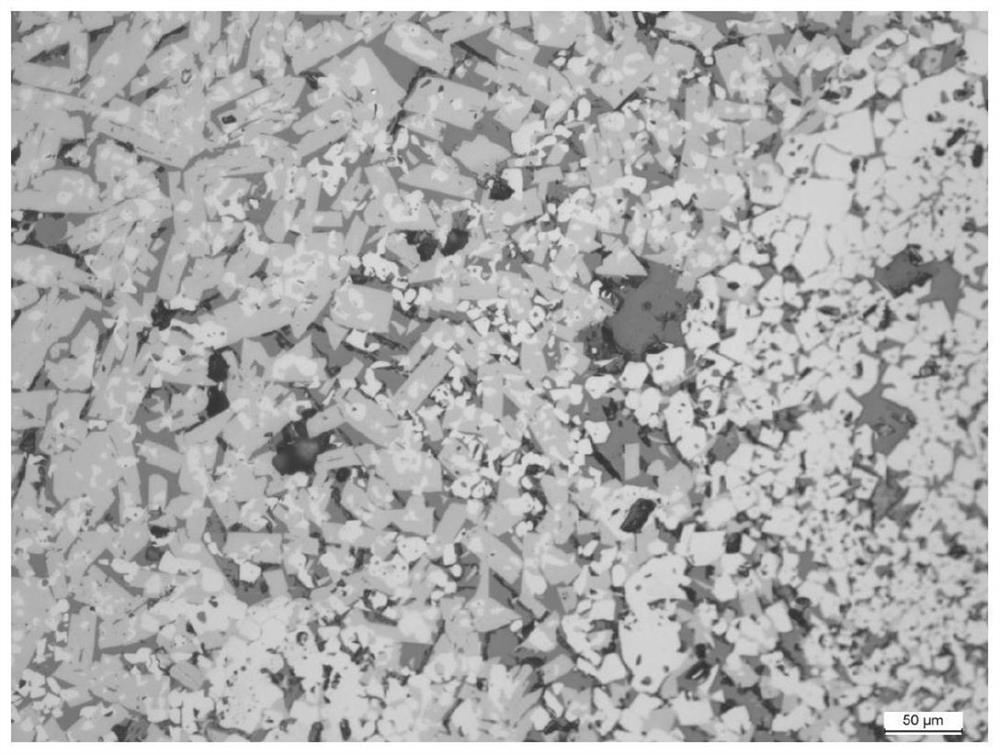

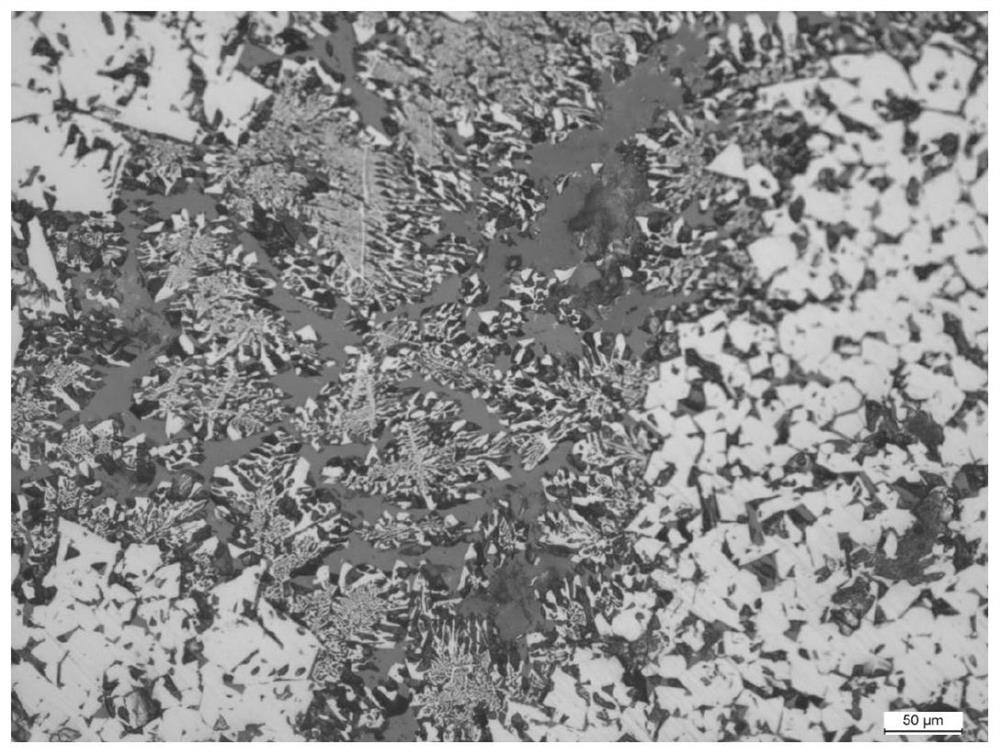

Embodiment 1

[0022] Embodiment 1: prepare additive according to following mass parts: H 3 BO 3 15 parts, CaCl 2 72 parts, NaCl 10 parts, KMnO 4 2 parts; take 0.02kg of additives and dissolve them in 2kg of water to make an additive solution; sintering cup test: use a 50kg sintering cup and 40kg of sintering mixture, add the prepared additive solution and mix well during the first mixing, and use a roller for the second mixing ball For the pelletizing machine, the pelletizing time is 8 minutes, and the moisture content of the sintering mixture is controlled at about 7.5%. In order to prevent the liquid phase generated during the sintering process from adhering to the grate bars, 1 kg of sintered ore with a particle size of 10-16 mm is placed on the grate bars of the sintering cup as the bottom material, and the amount of sintering mixture is controlled at about 40 kg. Layer thickness control is 650mm. Liquefied petroleum gas is used for sintering ignition, the sintering ignition tempe...

Embodiment 2

[0023] Embodiment 2: prepare additive according to following mass parts: H 3 BO 3 10 parts, CaCl 2 85 parts, NaCl 5 parts, KMnO 4 3 parts; Dissolve 0.02kg of additives in 2kg of water to make an additive solution; sintering cup test: use a 50kg sintering cup and 40kg of sintering mixture, add the prepared additive solution and mix well during the first mixing, and use a roller for the second mixing ball For the pelletizing machine, the pelletizing time is 8 minutes, and the moisture content of the sintering mixture is controlled at about 7.5%. In order to prevent the liquid phase generated during the sintering process from adhering to the grate bars, 1 kg of sintered ore with a particle size of 10-16 mm is placed on the grate bars of the sintering cup as the bottom material, and the amount of sintering mixture is controlled at about 40 kg. Layer thickness control is 650mm. Liquefied petroleum gas is used for sintering ignition, the sintering ignition temperature is contr...

Embodiment 3

[0024] Embodiment 3: prepare additive according to following mass parts: H 3 BO 3 20 parts, CaCl 2 67 parts, NaCl 7 parts, KMnO 4 1 part; Dissolve 0.02kg of additives in 2kg of water to make an additive solution; sintering cup test: use a 50kg sintering cup, sintering mixture 40kg, add the prepared additive solution and mix well during the first mixing, and use a roller for the second mixing ball For the pelletizing machine, the pelletizing time is 8 minutes, and the moisture content of the sintering mixture is controlled at about 7.5%. In order to prevent the liquid phase generated during the sintering process from adhering to the grate bars, 1 kg of sintered ore with a particle size of 10-16 mm is placed on the grate bars of the sintering cup as the bottom material, and the amount of sintering mixture is controlled at about 40 kg. Layer thickness control is 650mm. Liquefied petroleum gas is used for sintering ignition, the sintering ignition temperature is controlled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com