Fluid-driven tunneling device

A fluid-driven and fluid-dynamic technology, applied in mining equipment, earth-moving, tunneling, etc., can solve the problems of difficulty in meeting endurance, cumbersome maintenance and use, complicated motor structure, etc., and achieves good driving effect, simple structure and large torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

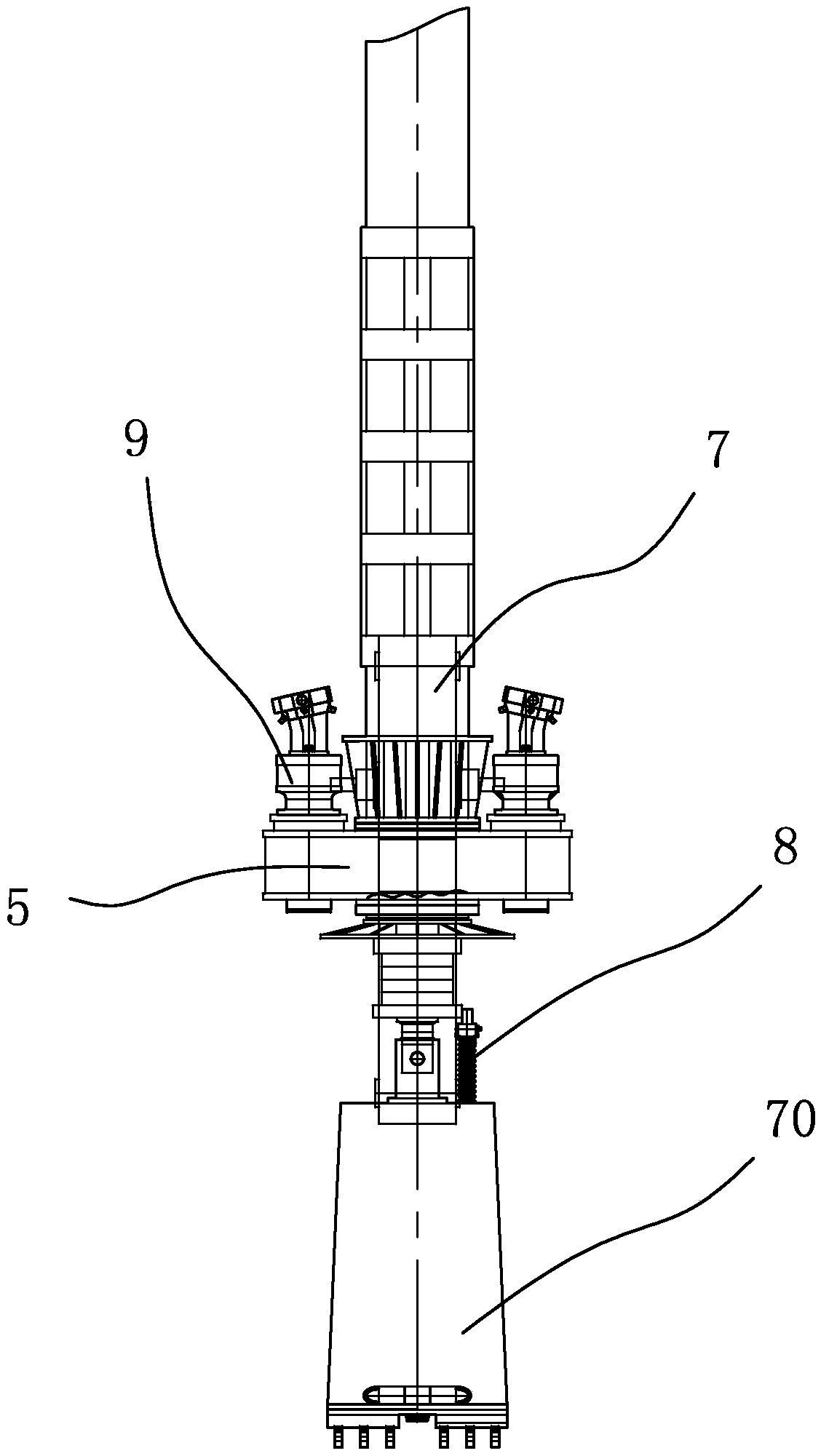

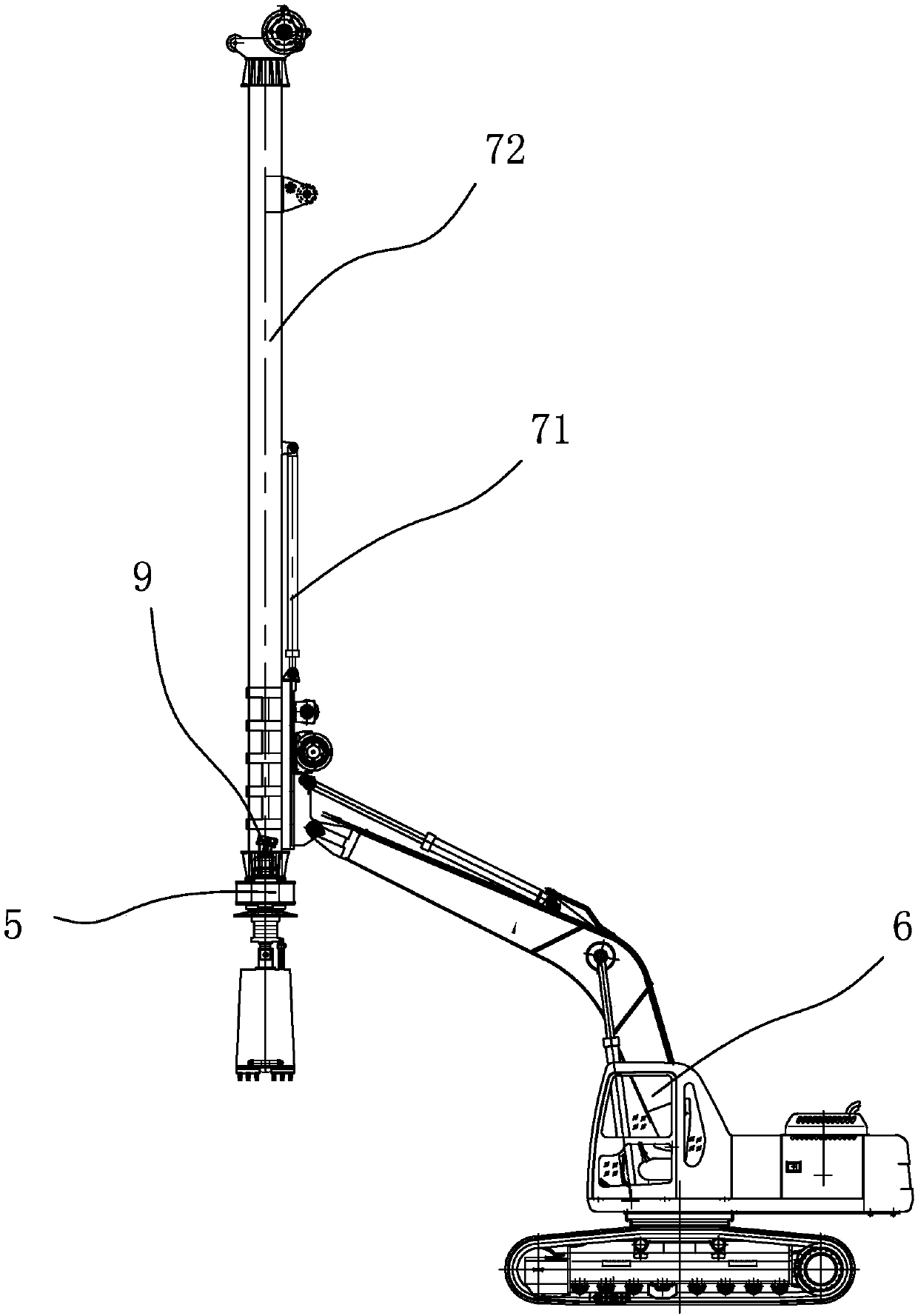

[0051] combine figure 1 with figure 2 As shown, this embodiment provides a fluid-driven tunneling device, which includes a mounting base 5, which has a through hole, and a rotating device 7 is rotatably arranged in the through hole, and two fluid The power device 9 is arranged on the installation base 5 and is respectively connected to the rotation device 7 by transmission.

[0052] The front end of the rotating device is provided with an operating device 8. In this embodiment, the operating device 8 is a drill bit for drilling and excavating the ore rock. The installation base 5 is arranged on the lifting arm of a crawler-type mobile device 6, and the inclination angle can be adjusted. The lifting arm also has a pull-down oil cylinder 71, and the pull-down oil cylinder 71 acts on the upper end 72 of the rotating device 7. , to be used for pressing down the operating device 8.

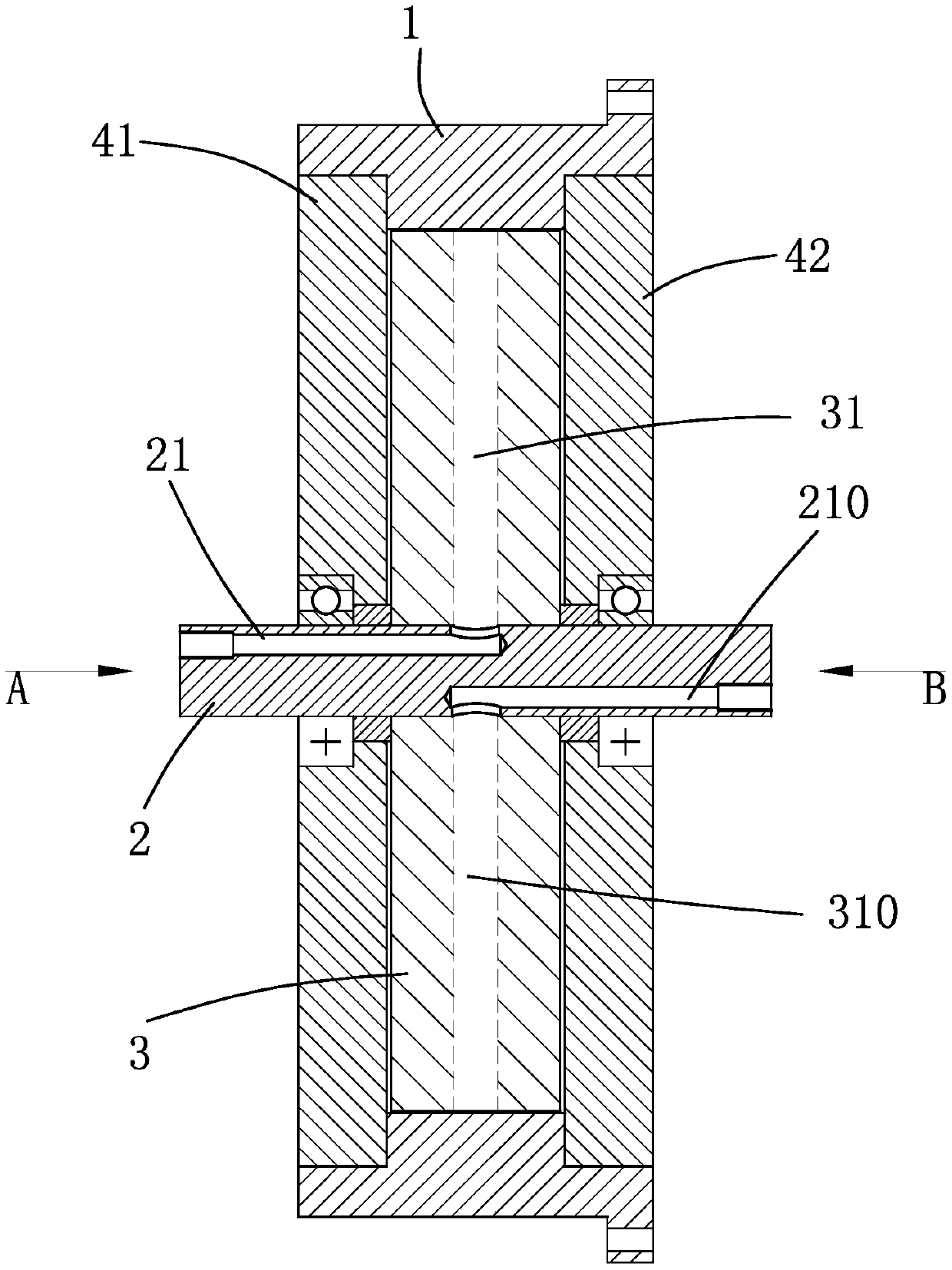

[0053] see Figure 3 to Figure 6, the fluid power device of this embodiment, it comprises an o...

Embodiment 2

[0073] The fluid-driven tunneling device of this embodiment is basically the same as Embodiment 1, and its main difference is:

[0074] see Figure 8 to Figure 11 , the fluid power device includes 2 independent work units to form a secondary drive structure, that is, the core body 3 is provided with 2 fluid passages along the circumferential direction, and each fluid passage includes an inlet flow passage 31 and a secondary flushing flow passage 300 of more than one stage and The drainage channel is arranged along the circumferential direction of the core body 3 . The fluid power device includes an outer ring 1, a plurality of driving recesses 11 are arranged on the inner ring surface of the outer ring; a core body 3 is coaxially arranged in the outer ring 1 and can rotate relative to the outer ring, and the outer ring surface of the core body is provided with 2 groups of spouts, discharge ports, and at least one flushing channel between each group of spouts and discharge por...

Embodiment 3

[0077] This embodiment is basically the same as Embodiment 1, and the main difference is that the fluid power device of the present invention includes 4 or more independent working units to form a multi-stage drive structure, and 3 or more fluid lines are arranged on the core along the circumferential direction. Channels, each fluid channel includes an inlet channel and a secondary flushing channel of more than one stage, and is arranged along the circumference of the core body and a drainage channel, and the inlet channel and the drainage channel are arranged on the mating surfaces of the left and right cores. The shaft is provided with the number of inlet shafts and outlet shafts corresponding to the number of fluid channels. The compressed fluid enters from the inlet shaft of the shaft, and is ejected through the core body inlet channel to act on the driving recess of the outer ring to drive the outer ring to rotate. Do work to realize the continuous output of power, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com