Compressor blade size accurate measurement device

A technology for accurate measurement of compressor blades, applied to mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve problems such as low work efficiency, increased production costs, and low automation level, and achieve fast efficiency, high precision, and avoid measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

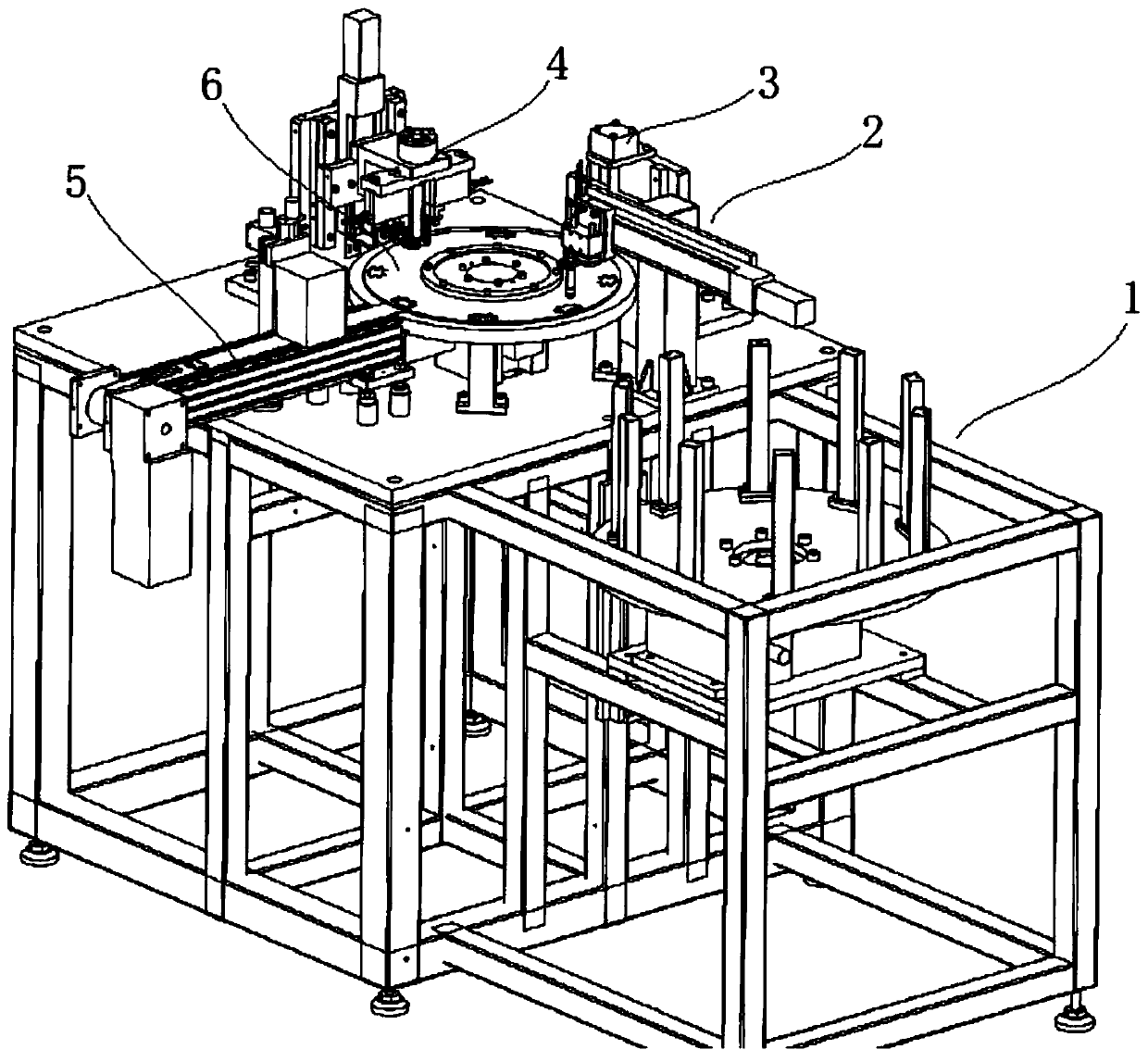

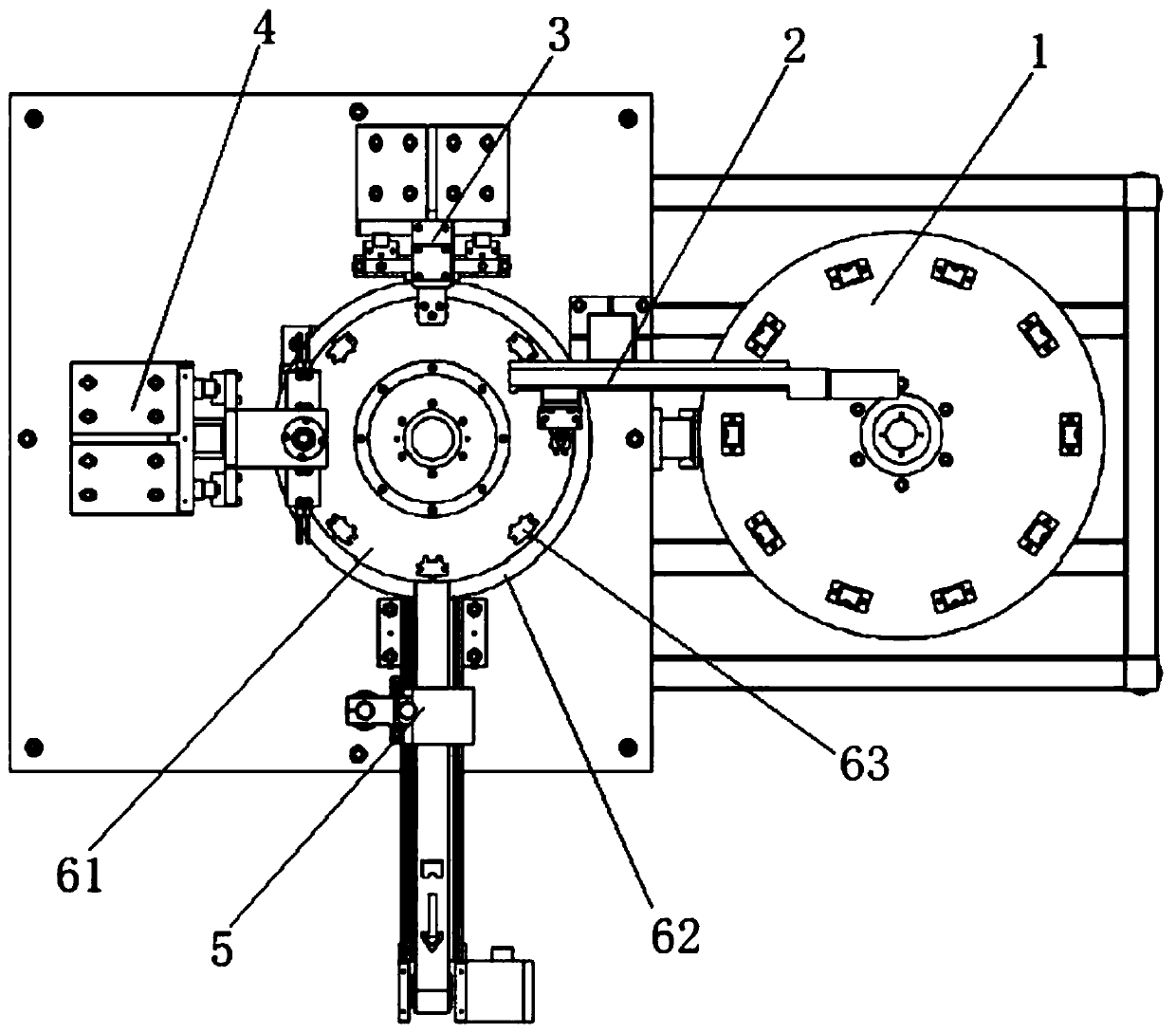

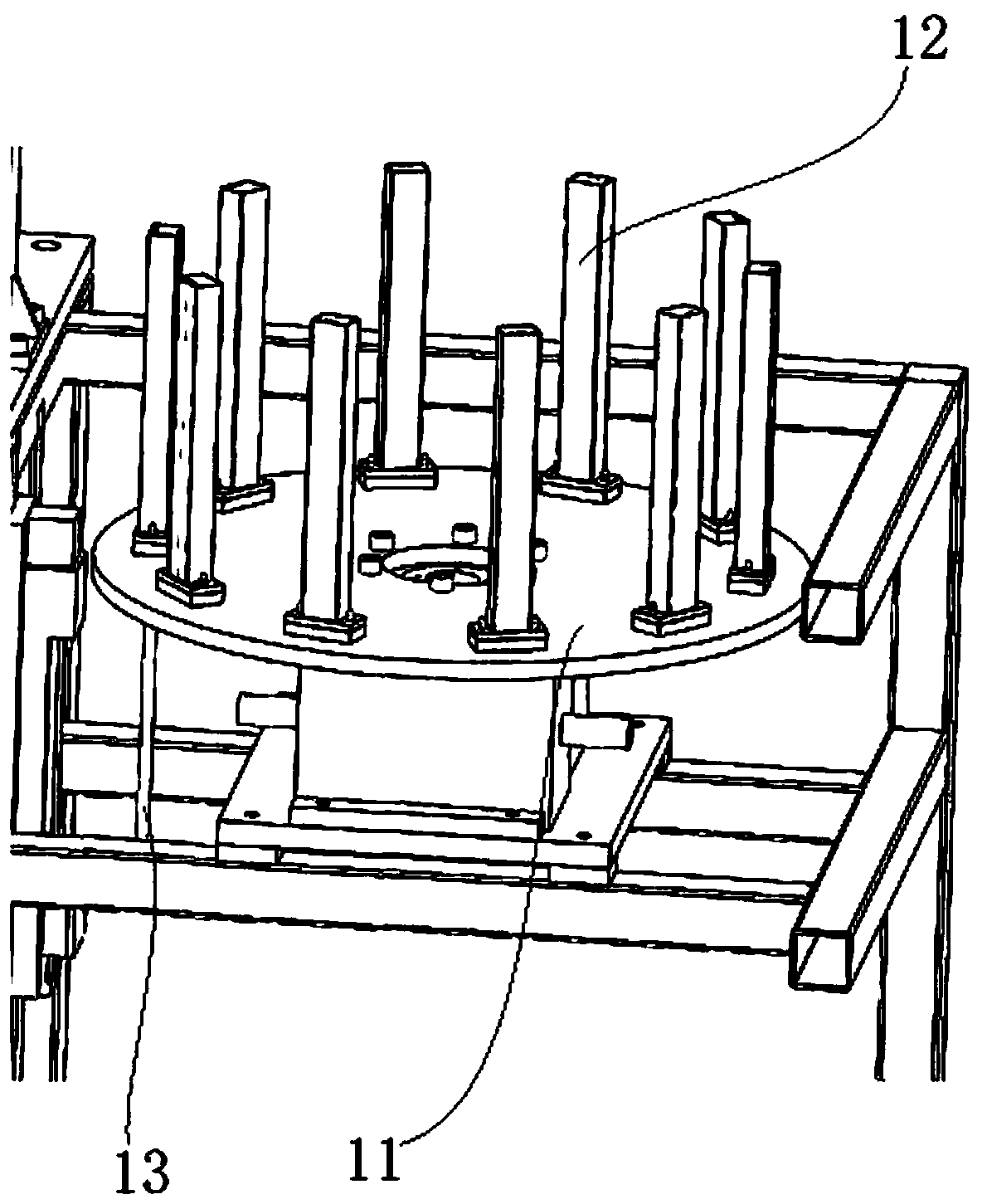

[0033] like figure 1 , 2 As shown, the precise measuring device for compressor blade size includes an assembly line test platform 6 capable of driving the compressor blades to move and position along the assembly line. The assembly line test platform 6 is provided with a compressor blade feeding device 1 and a compressor blade unloading device 5 And the first measuring device 3 for measuring the thickness and flatness of the compressor blade and the width measuring device 4 for measuring the width of the compressor blade located between the compressor blade loading device 1 and the compressor blade unloading device 5 .

[0034] The assembly line test platform 6 includes a second turntable 61 driven by a servo motor to move intermittently. There are a plurality of blade positioning openings 63 recessed on the outside of the second turntable 61 toward the center, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com