Scanning interference photoetching system

A lithography system and scanning interference technology, applied in the field of optical instruments and meters, can solve the difficulties of phase solution, subdivision and direction judgment, poor anti-interference ability, difficult to achieve high-precision measurement, and difficult to realize high-precision variable-period grating manufacturing, etc. problem, to achieve the effect of high laser utilization rate and high locking precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means and effects of the present invention for solving technical problems, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the provided accompanying drawings are schematic and mutually exclusive They are not drawn to scale or scale, and therefore the drawings and specific examples are not intended to limit the scope of protection claimed by the invention.

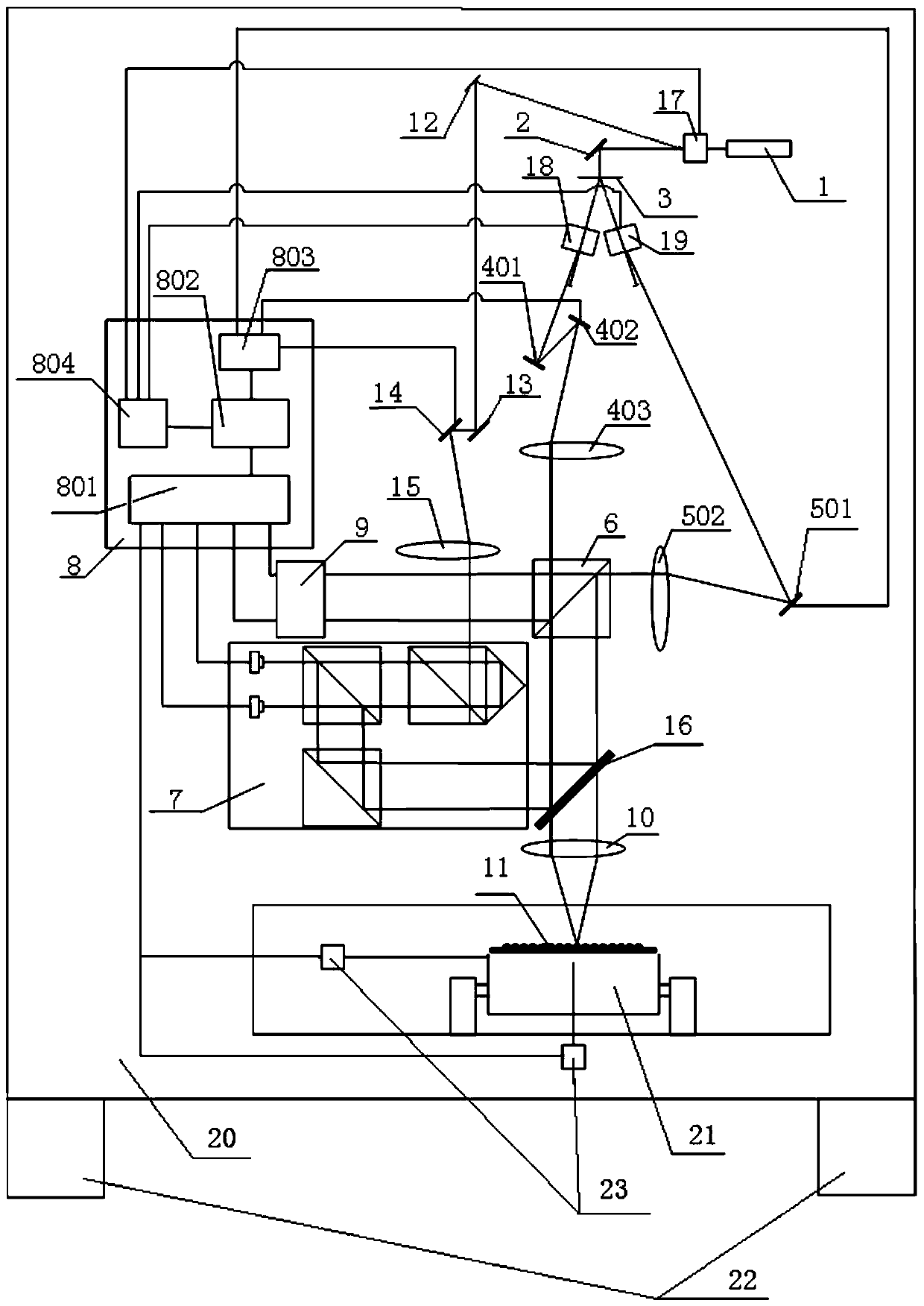

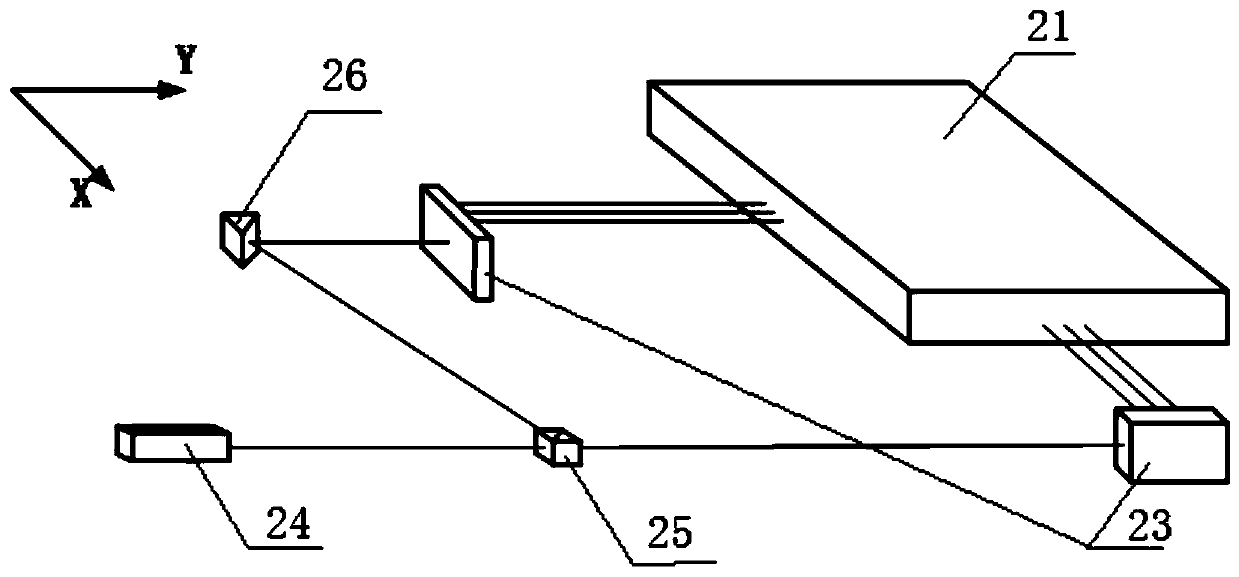

[0036] Such as figure 1 An optional embodiment of the scanning interference lithography system shown, the system includes:

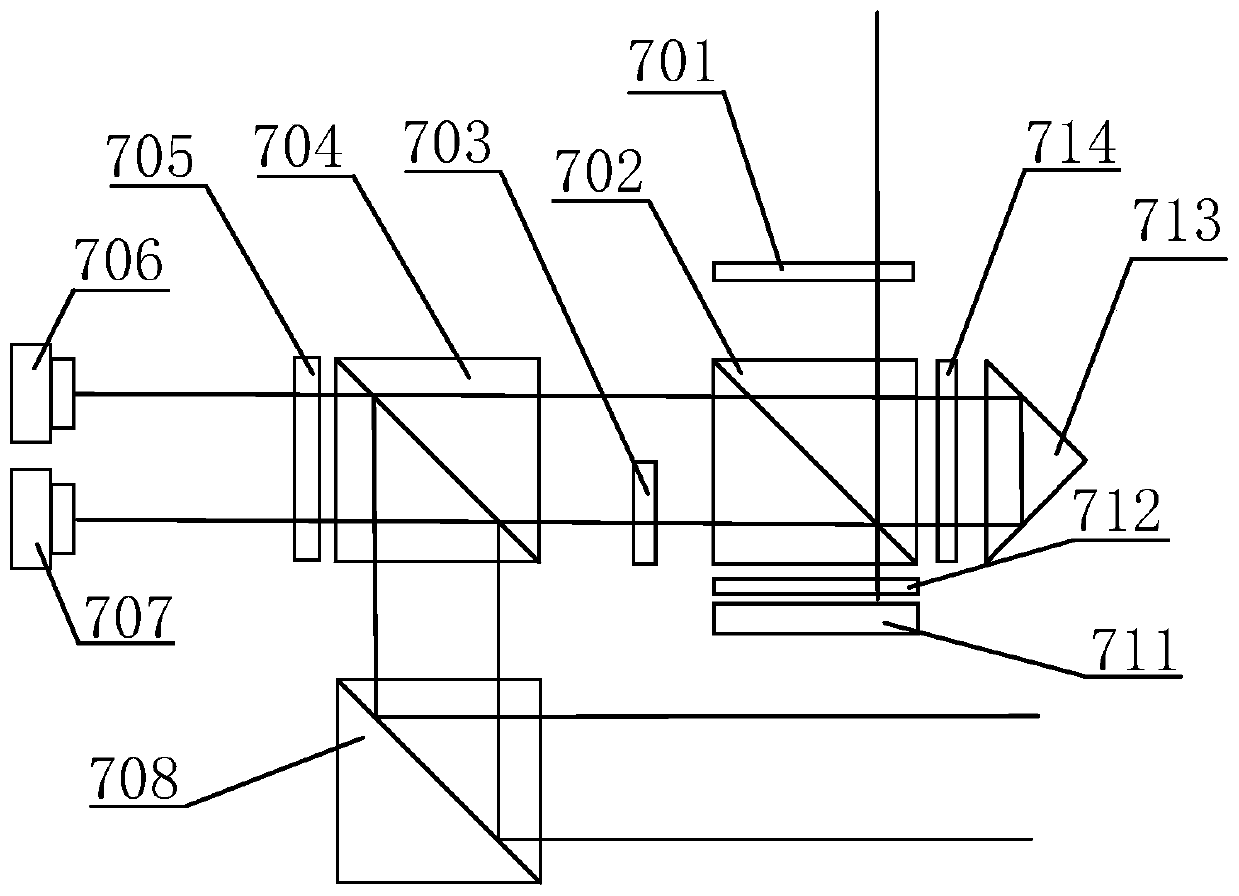

[0037] Heterodyne optical path: the laser light emitted by the laser 1 passes through the first phase modulator 17 to separate the zero-order diffracted light and the first-order diffracted light, wherein the first-order diffracted light passes through the third reflector 12, the fourth reflector 13 and the third reflector in turn. After b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com