Array fiber laser

A technology of arrayed optical fibers and lasers, applied in the direction of laser devices, etc., can solve the problems of large system volume, low integration, stress damage, etc., and achieve the effects of reducing volume and weight, increasing integration, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and embodiments.

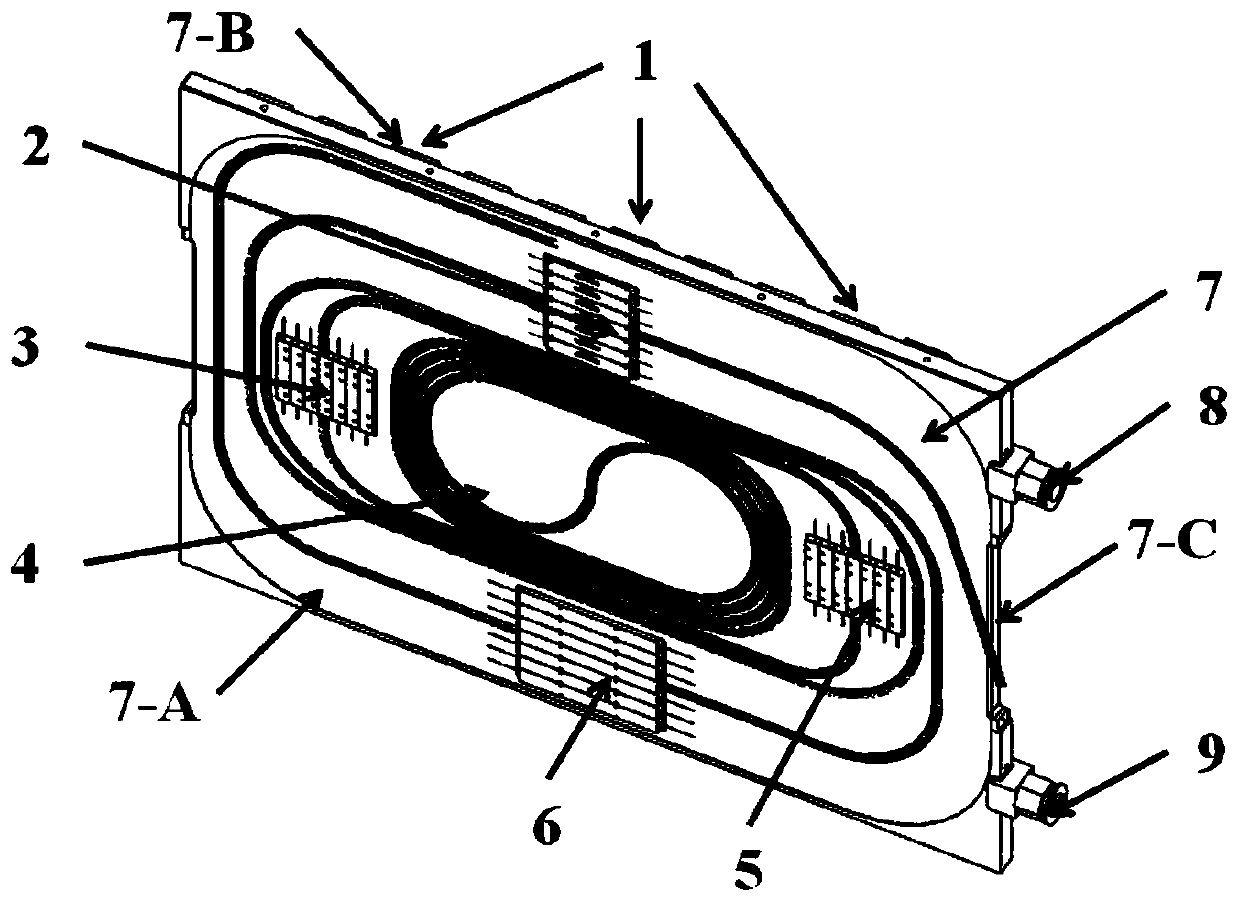

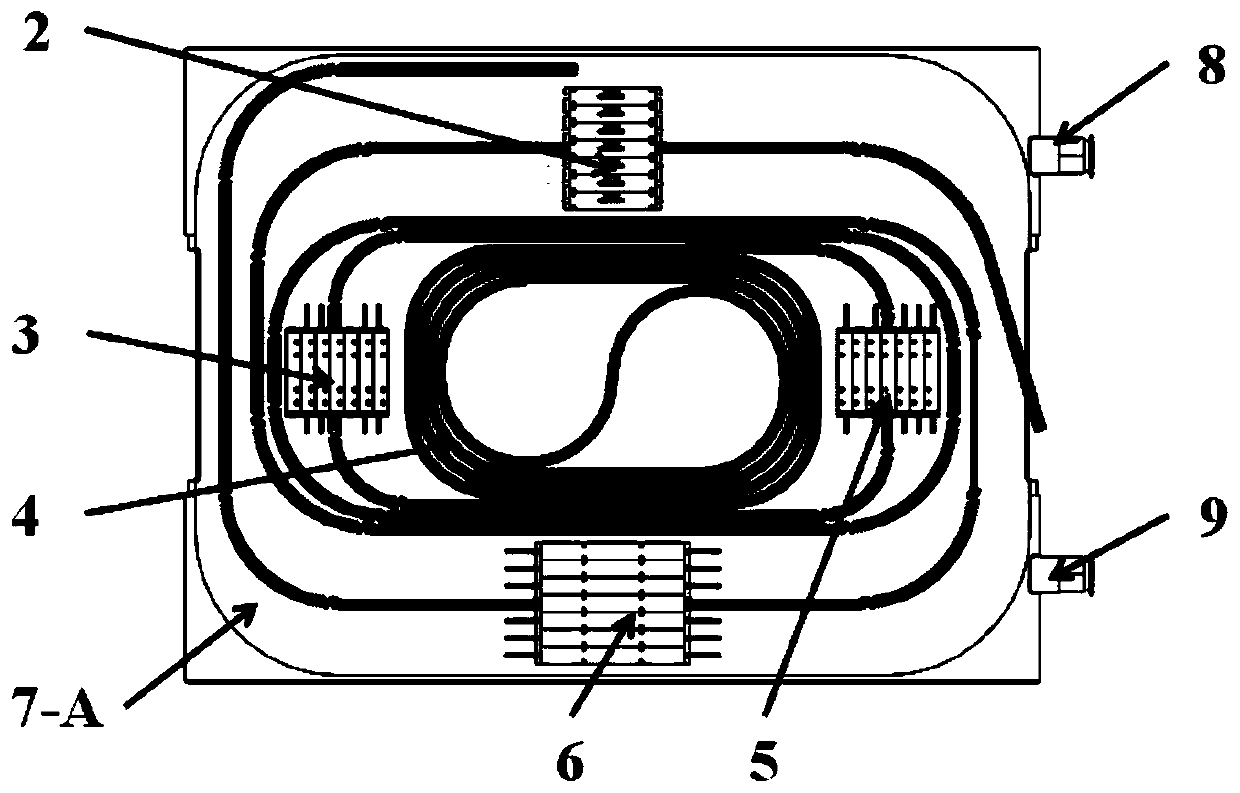

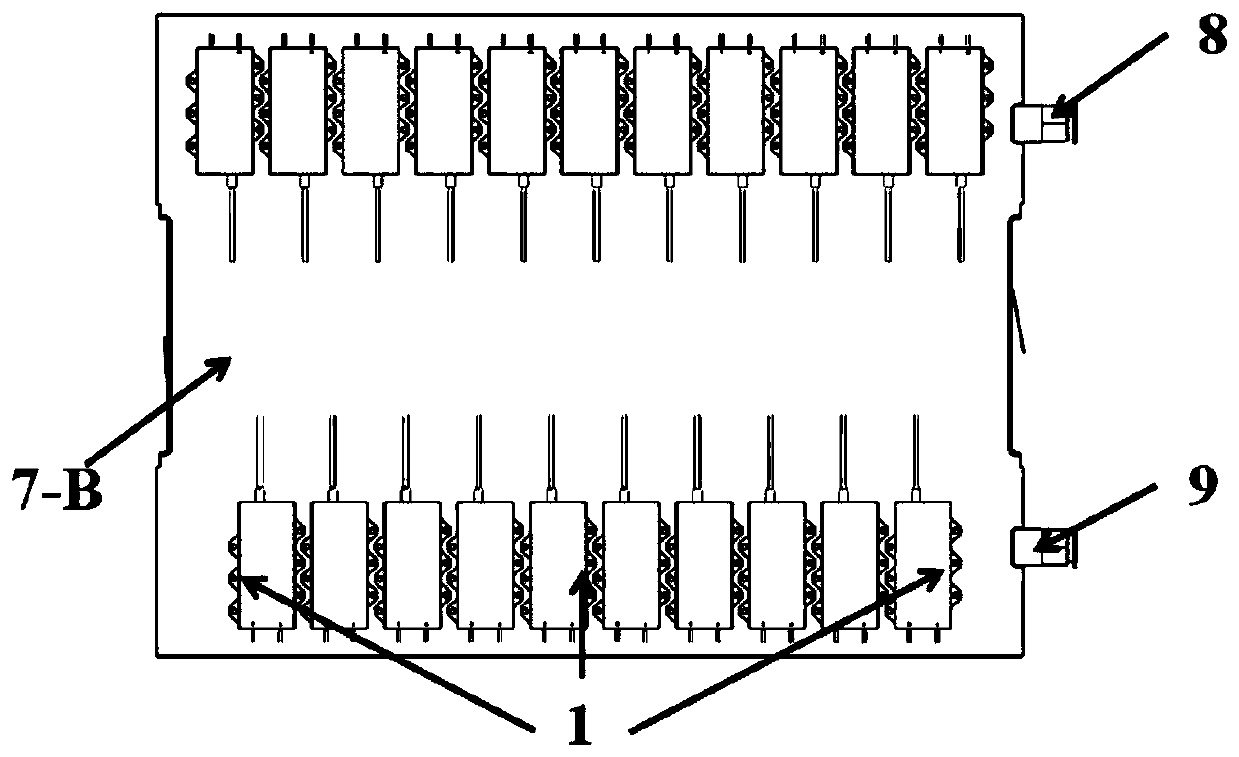

[0032] This embodiment provides an array fiber laser, whose structure refers to figure 1 , 2 And 3, the array fiber laser includes an array fiber laser including a fiber-coupled semiconductor laser array 1, a pump beam combiner array 2, a high-reflection fiber grating array 3, and a gain fiber array 4 that are fixed on the fiber optic device panel 7 and connected in sequence. A low-reflection fiber grating array 5 and a cladding optical filter array 6 . The pump beam combiner array 2, the high reflection fiber grating array 3, the gain fiber array 4, the low reflection fiber Bragg grating array 5 and the cladding optical filter array 6 of the present embodiment correspond to the respective pump beam combiners, high reflection The number of fiber gratings, gain fibers, low-reflection fiber gratings and cladding light filters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com