A deodorizing fragrance composition

A technology of composition and fragrance, which is applied in the direction of disinfection and deodorization, etc., can solve the problems of household materials such as strong smell, long duration, and human health hazards, and achieve effective sterilization and long-term removal of formaldehyde, good air optimization effect, The effect of the long-lasting air-optimizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A deodorizing fragrance composition, using clinoptilolite as a raw material to prepare modified zeolite, clinoptilolite is baked at 500°C for 2 hours, cooled naturally to obtain zeolite particles, and the zeolite particles are ground to obtain zeolite powder. Add 2 parts of zeolite powder to tetramethylammonium hydroxide, add 1 part of nano-silver particles and 1 part of nano-titanium dioxide particles at the same time, and ultrasonically shake and stir at 118 ° C for 0.5 hours. The resulting mixture is rinsed with deionized water and then dried. A modified zeolite is obtained. Formula by weight percentage is: 60% modified zeolite; 15% tourmaline; 10% zinc ricinoleate; 9% jasmine essential oil; 5% propylene glycol; Jasmine essential oil and propylene glycol are stirred and mixed, then tourmaline and deionized water are added, and stirred to obtain a finished product.

Embodiment 2

[0029] A deodorizing fragrance composition, using clinoptilolite as a raw material to prepare modified zeolite, clinoptilolite is baked at 700°C for 0.5 hours, and then cooled naturally to obtain zeolite particles, which are ground to obtain zeolite powder, which is taken Add 2 parts of zeolite powder into tetramethylammonium hydroxide, add 1 part of nano-silver particles and 1 part of nano-titanium dioxide particles at the same time, and ultrasonically shake and stir at 90 ° C for 1.5 hours. The resulting mixture is rinsed with deionized water and then dried. A modified zeolite is obtained. The formula by weight percentage is: 70% modified zeolite; 10% tourmaline; 12% zinc ricinoleate; 5% chamomile essential oil; 2% polyethylene glycol; 1% deionized water, adding castor oil to the modified zeolite Zinc acid, chamomile essential oil and polyethylene glycol are stirred and mixed, and then tourmaline and deionized water are added and stirred to obtain a finished product.

Embodiment 3

[0031] A deodorizing fragrance composition, using clinoptilolite as a raw material to prepare modified zeolite, clinoptilolite is baked at 600°C for 1.5 hours, and then naturally cooled to obtain zeolite particles, which are ground to obtain zeolite powder, which is taken Add 2 parts of zeolite powder to tetramethylammonium hydroxide, add 1 part of nano-silver particles and 1 part of nano-titanium dioxide particles at the same time, and ultrasonically vibrate and stir at 110 ° C for 1 hour. The resulting mixture is rinsed with deionized water and then dried. A modified zeolite is obtained. Formula by weight percentage is: 65% modified zeolite; 13% tourmaline; 8% zinc ricinoleate; 8% orchid essential oil; 4% propylene glycol; Orchid essential oil and propylene glycol are stirred and mixed, then tourmaline and deionized water are added, and the finished product is obtained by stirring.

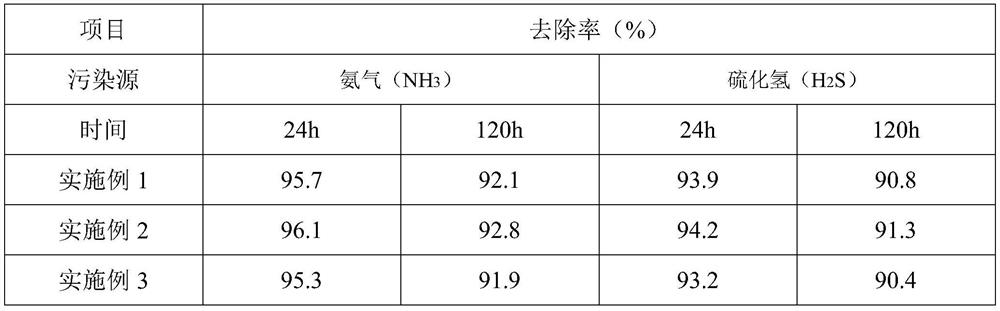

[0032] The obtained products were tested for deodorization performance and fragrance persis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com