Technical equipment for emulsifying and activating microbial inoculum

A technology of inoculum and compound inoculum, applied in the field of remediation and soil improvement, can solve the problems of poor removal effect, secondary pollution and high cost, and achieve the effects of improving fertility, long-term removal and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

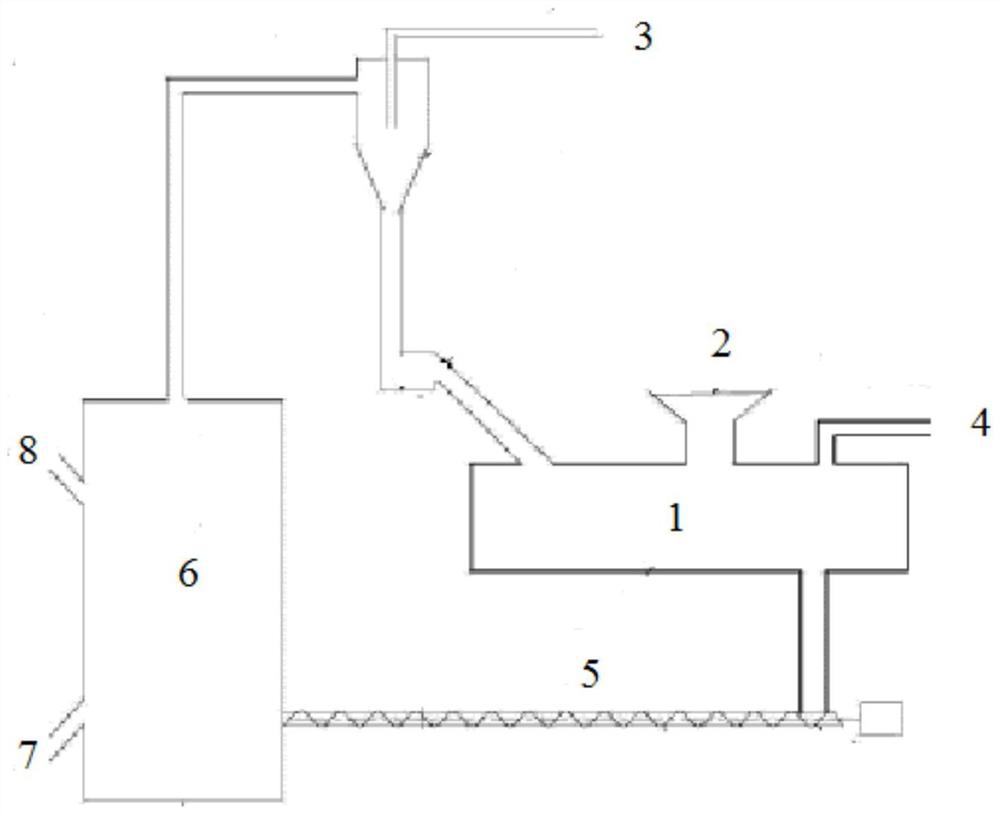

Image

Examples

Embodiment 1

[0065] The corn stalks are washed with water, soaked in 0.01M dilute hydrochloric acid for 2 hours, air-dried to a water content of 15-18%, and chopped. In the pyrolysis furnace, blow nitrogen to purge, and then add straw and a calcium mixture accounting for one-fifth of the weight of the straw through the feeding port (the weight ratio of calcium oxide to calcium carbonate is 2:1, and the temperature is raised to 450-550°C. Insulate the reaction for 2 hours while maintaining the circulation of nitrogen.

[0066] Then lower the temperature to room temperature to obtain semi-coke, crush it, and press it together with the pyrolysis oil obtained by condensing the pyrolysis gas to form pellets with a particle size of 2-4 mm.

[0067] Expand the culture of yeast, Bacillus megaterium, Halomonas, Bacillus subtilis and Pseudomonas aeruginosa to a concentration of 10 9 Each / mL liquid bacteria, mixed according to the ratio of liquid mass ratio of 2:1.8:3.2:3.2:1, while adding the activ...

experiment example 1

[0069] The tested soil is about 5m 3 , collected from a polluted site at a sampling depth of 30-50 cm. A variety of aromatic hydrocarbons used in the experiment were purchased from Sigma Company in the United States and were of analytical grade. Selected by manual sieving, the 30mm undersize was used as the original soil for the restoration experiment. The specific physical and chemical parameters of the soil are as follows: pH is 7.4-8, moisture content is 10%, porosity is 36.5%, vertical permeability coefficient is 1.78×10 - 3 cm / s, the soil texture is sandy silt, the TOC is 1.18%, the content of naphthalene is 42 mg / kg, the content of benzopyrene is 55 mg / kg, and the content of 5-6 polycyclic aromatic hydrocarbons is 47 mg / kg.

[0070] Add the improver according to the ratio of compound soil improver to soil mass at 4:100, turn over the pile regularly and replenish water properly during the restoration process, and monitor indicators (including polycyclic aromatic hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com