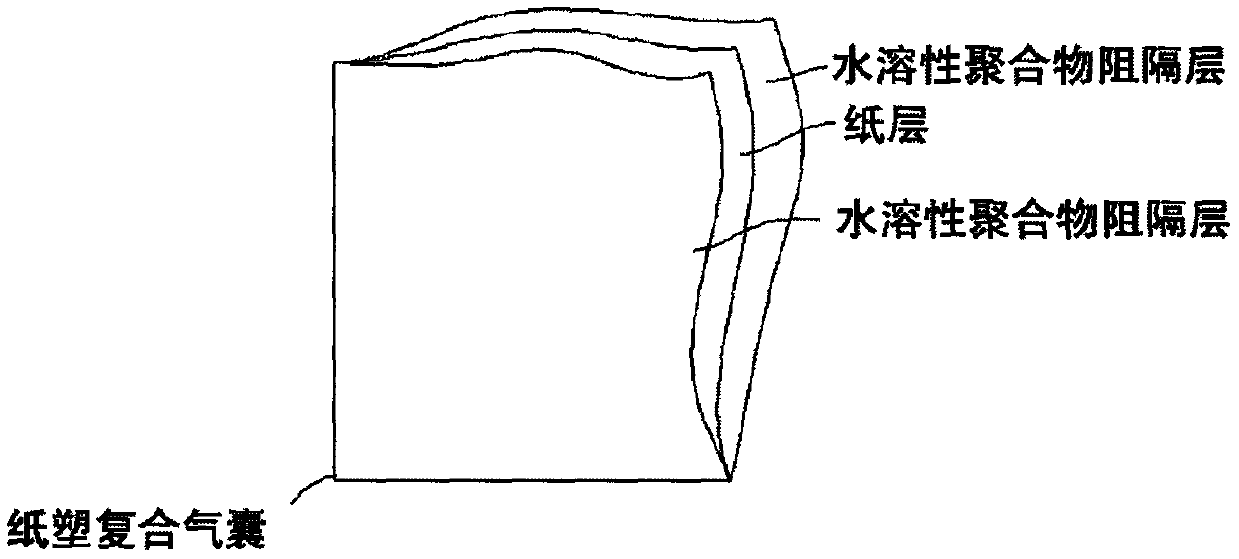

Paper-plastic composite airbag for pipeline welding argon filling plugging and preparation method of airbag

A technology of paper-plastic composite and air bag, which is applied in the direction of welding equipment, welding medium, pipe/pipe joint/pipe fitting, etc., to achieve the effect of improving welding quality, high gas barrier property and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

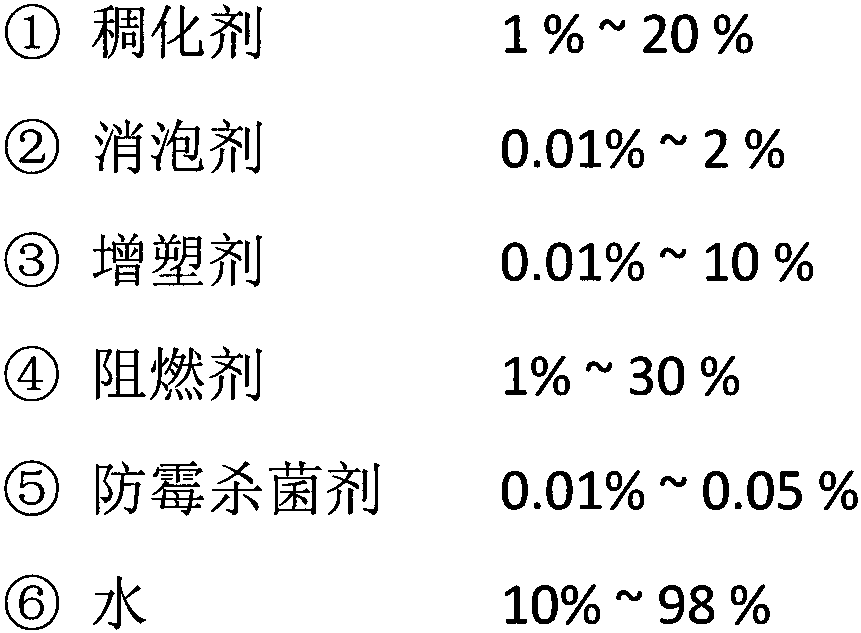

[0022] Disclosed is a paper-plastic composite airbag for pipeline welding and filling with argon, which is prepared from polyvinyl alcohol, organic defoaming agent, glycerin, flame retardant, water and other components. Its preparation method comprises the following steps:

[0023] (1) Under normal temperature and pressure, dissolve 158.4g of polyvinyl alcohol in 1,320ml of water containing 15g of glycerol, stir at 1000rpm for 10min, add 7.5g of silicone defoamer dropwise, dissolve and keep warm for 2~ 2.5 hours. Then add 180g of flame retardant and 0.1g of isothiazolinone antifungal and fungicide into the solution, stir thoroughly for 20min until completely dissolved and evenly dispersed. Stop stirring and stand for 2h.

[0024] (2) Cut the paper into 10-inch circles according to the pipe size. Uniformly coat a layer of the solution prepared in step (1) on its surface, and heat it at 95° C. to make it completely dry.

Embodiment 2

[0026] Disclosed is a paper-plastic composite airbag for pipeline welding and filling with argon, which is prepared from polyvinyl alcohol, organic silicon defoamer, triethanolamine, flame retardant, water and other components. Its preparation method comprises the following steps:

[0027] (1) Under normal temperature and pressure, dissolve 162g of polyvinyl alcohol in 1350ml of water containing 15g of glycerol, stir at 1000rpm for 10min, add 7.5g of silicone defoamer dropwise, dissolve and keep warm for 2 to 2.5 hours . Then add 7.5g of triethanolamine and 150g of flame retardant to the solution, stir well for 20min until completely dissolved and evenly dispersed. Stop stirring and stand for 2h.

[0028] (2) Cut the paper into a 12-inch circle according to the pipe size. Uniformly coat a layer of the solution prepared in step (1) on its surface, and heat it at 95° C. to make it completely dry.

[0029] (3) Step (2) was repeated to prepare 3-layer and 4-layer paper-plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com