Supercritical liquid hydrogen storage system

A storage system, supercritical technology, applied in gas/liquid distribution and storage, fixed-capacity gas storage tanks, non-pressure containers, etc., can solve the problems of container tank danger, liquid hydrogen waste, pressure rise, etc., and achieve safety guarantee , the effect of increasing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

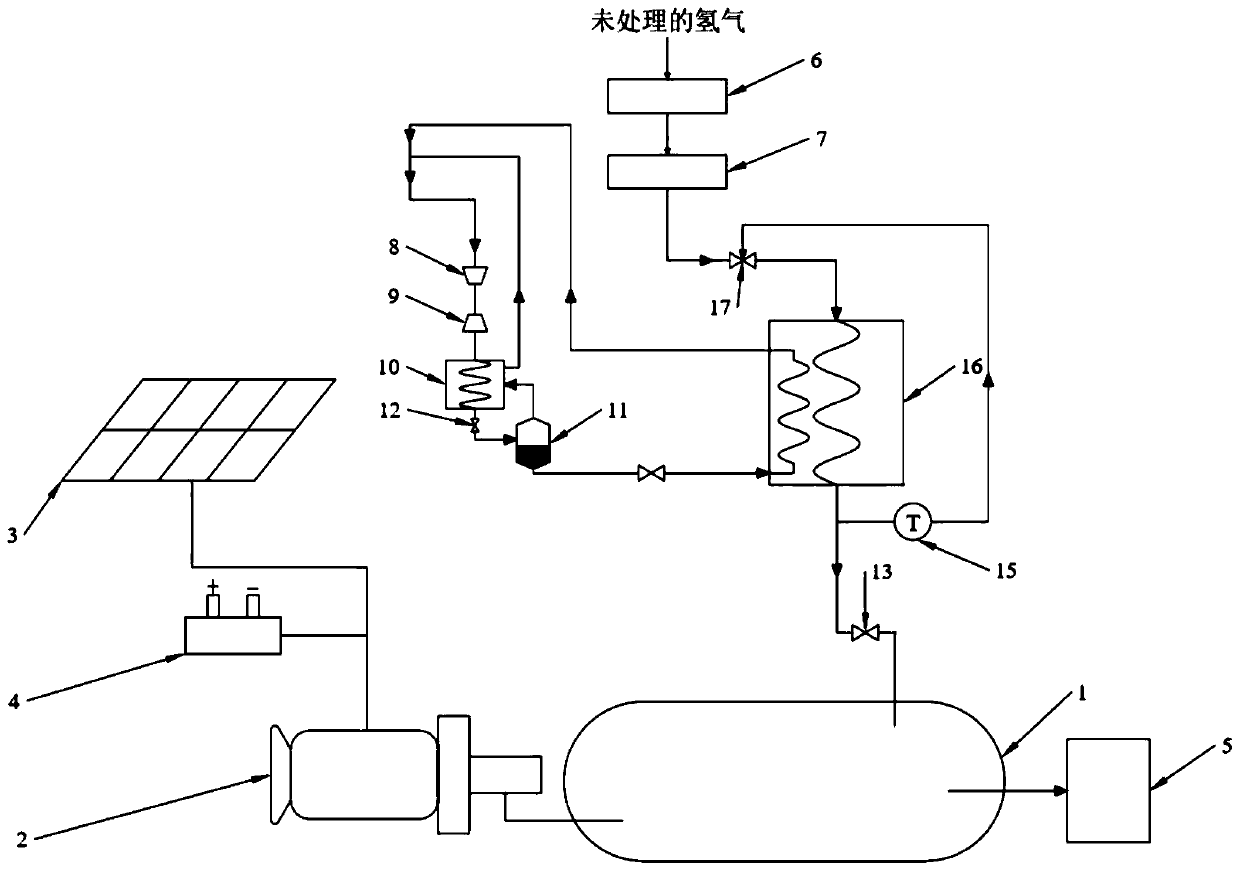

[0028] The supercritical liquid hydrogen storage system includes a hydrogen processing part, a supercritical hydrogen storage part 1 and a cooling part.

[0029] Such as figure 1 As shown, the hydrogen processing unit includes a liquid nitrogen cooling unit, a temperature sensor 15 , a flow regulating valve 17 , and a hydrogen purification device 6 , a hydrogen pressurization device 7 , and a hydrogen heat exchanger 16 connected in sequence through pipelines.

[0030] The flow regulating valve 17 is set in the pipeline between the hydrogen pressurization device 7 and the hydrogen heat exchanger 16, the temperature sensor 15 is set in the pipeline connecting the outlet of the hydrogen heat exchanger 16 and the flow regulating valve 17, and the flow valve 13 is set In the pipeline 22 between the hydrogen heat exchanger 16 and the supercritical hydrogen storage part 1 .

[0031] The liquid nitrogen cooling unit includes an oil-free centrifugal turbo compressor 8 , a turbo expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com