Rapid phase-height mapping calibration method

A calibration method and height technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of time-consuming and accumulated errors of the displacement table, the equipment is not easy to carry, and accumulated errors, etc., to reduce random errors, solve system calibration problems, Effect of Improving Calibration Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

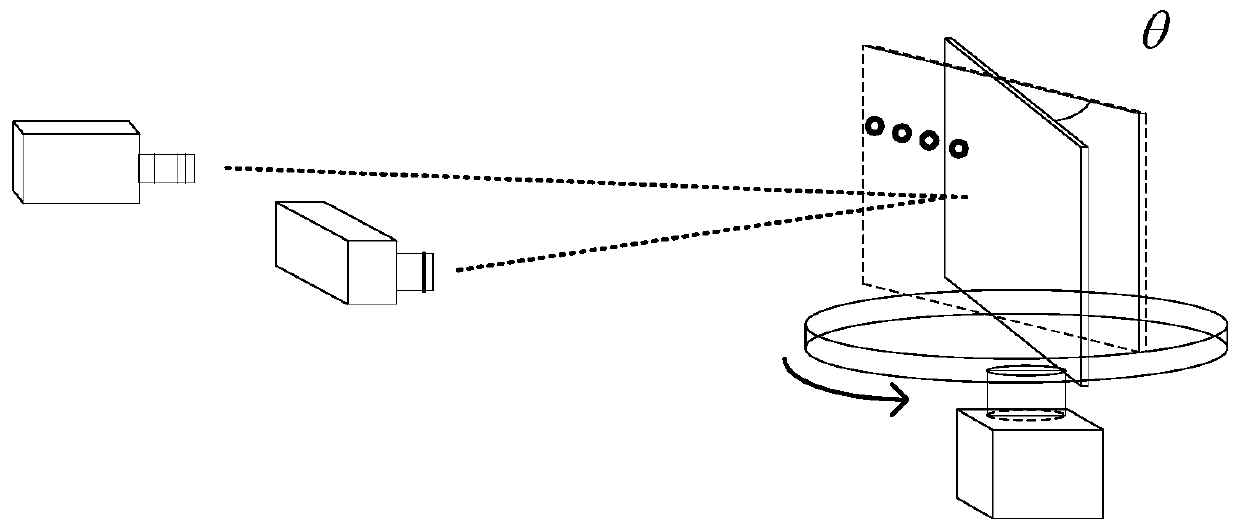

[0018] A fast phase-height mapping calibration method includes the following steps:

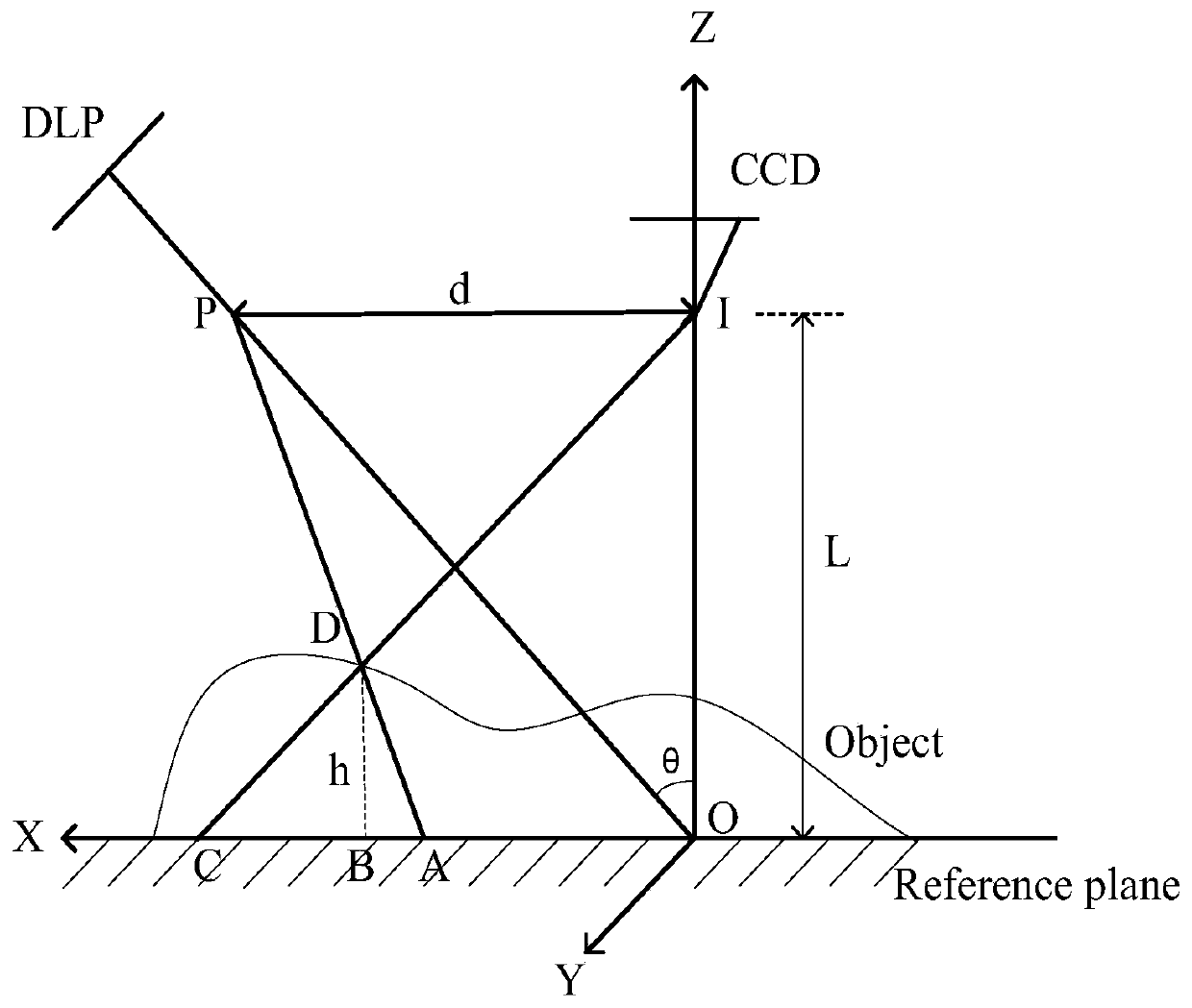

[0019] (1) Establish a three-dimensional measurement system. Such as figure 1 As shown, the system includes a DLP projector, a CCD camera and a reference plane; where the optical axis of the DLP projector and the optical axis of the CCD camera intersect at point O, the DLP projector and the CCD camera are at the same height, and the distance between them is d, Their distance from the reference plane is L;

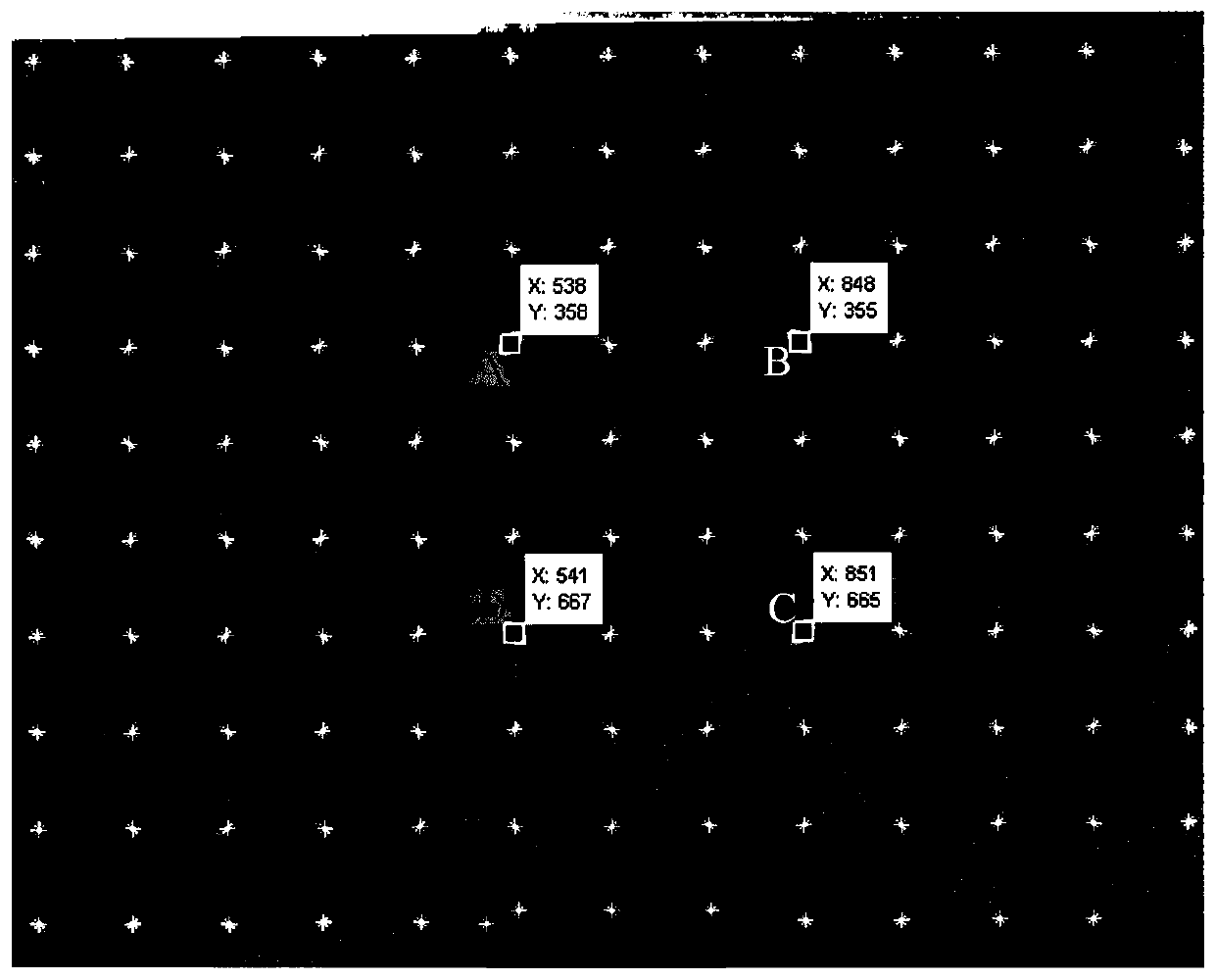

[0020] (2) Verticality calibration. Standard black and white checkerboards are used for verticality calibration, the checkerboard grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com