Preparation method of polyaniline/carbon composite material for cathode material of aqueous zinc ion battery

A zinc-ion battery, carbon composite material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cumbersome preparation process, achieve easy availability of raw materials, be conducive to large-scale production and application, experimental conditions and operations simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

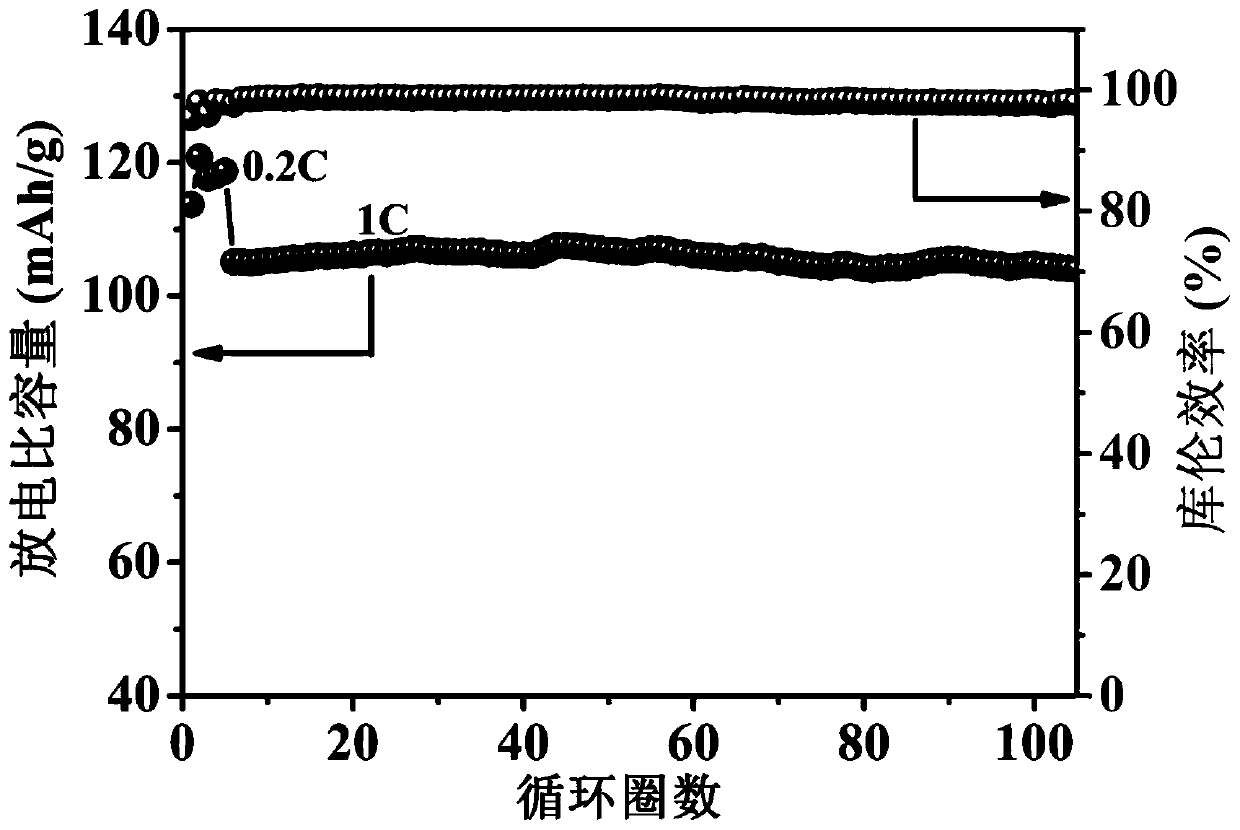

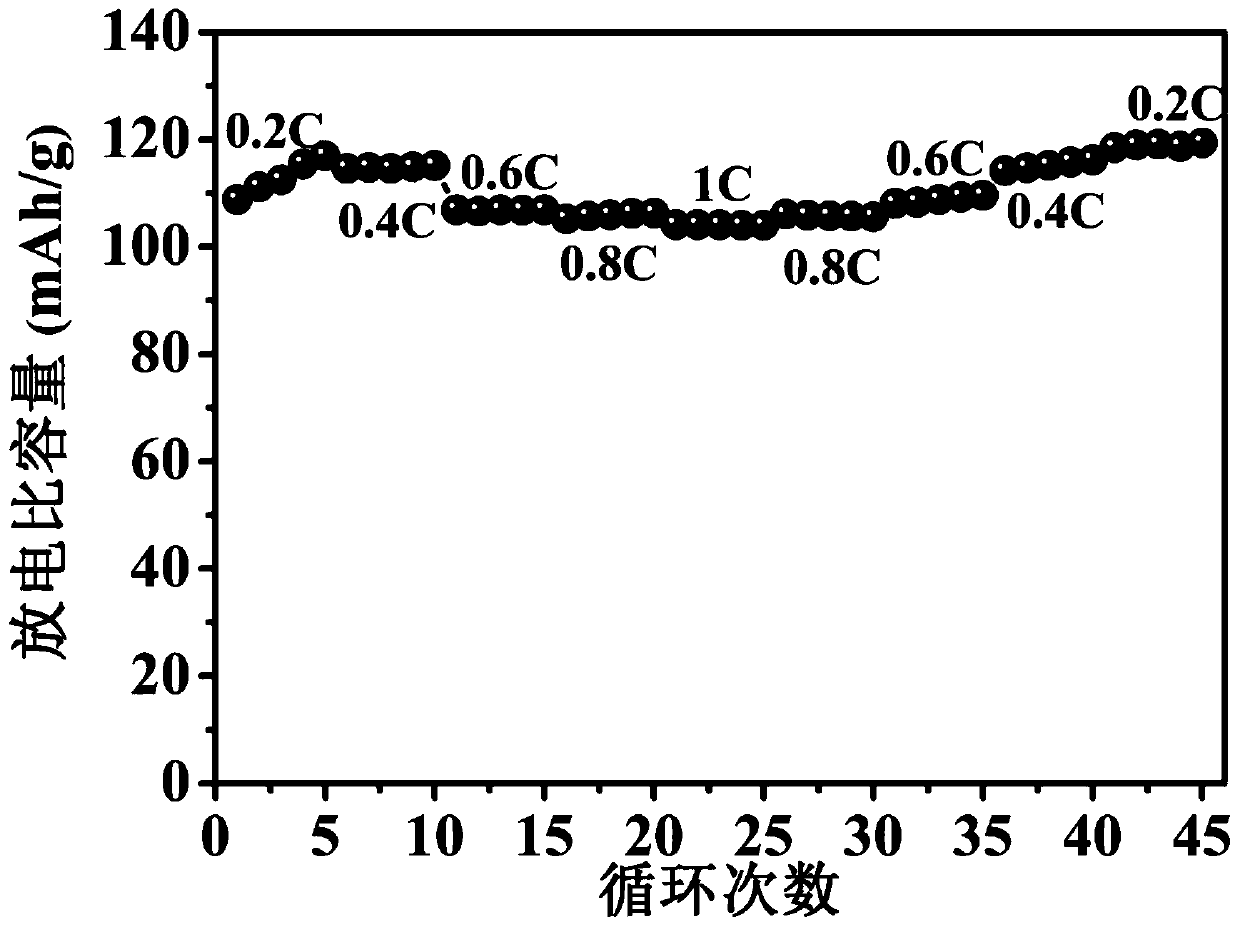

Embodiment 1

[0046] The production process of polyaniline / carbon composites is as follows:

[0047] (1) Take 250mL of hydrochloric acid with a concentration of 1mol / L, and cool down below 6°C in an ice-water bath;

[0048](2) While stirring, add 32g of aniline, divided into four times, with an interval of 3-5 minutes each time, and can be added when the temperature is below 6°C;

[0049] (3) Add 0.567g of activated carbon, stir and disperse for 30 minutes, cool down to below 4°C in an ice-water bath, then add manganese dioxide (preferably 2.64g), and react for 15 minutes;

[0050] (4) Take another 150 mL of hydrochloric acid with a concentration of 1 mol / L, add 84 g of ammonium persulfate, and stir to dissolve;

[0051] (5) Under the condition of stirring, drop the ammonium persulfate in the form of dropwise addition, and control the dripping in about 2 hours;

[0052] (6) After the ammonium persulfate is added dropwise, add 0.567g of acetylene black, continue to stir, react for 3h, and ...

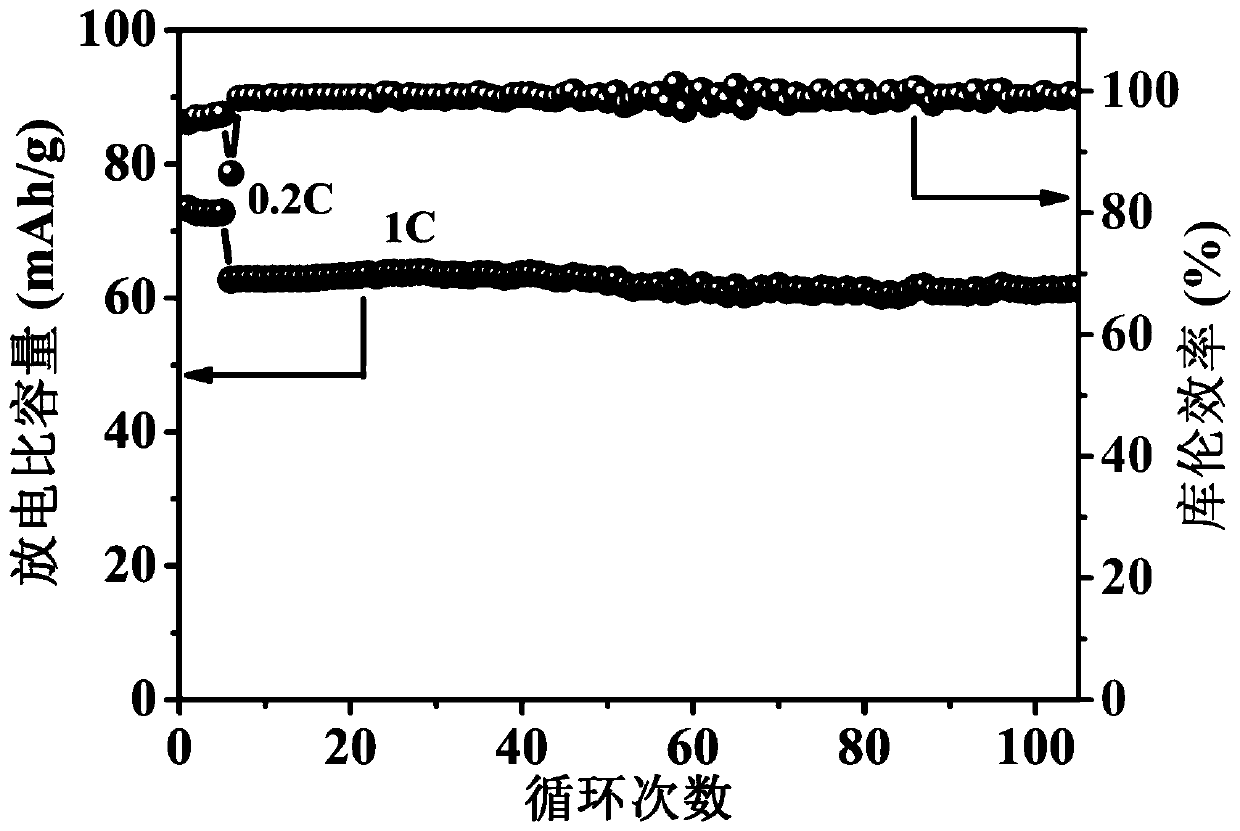

Embodiment 2

[0082] Embodiment 2 (being comparative example 1)

[0083] The production process of polyaniline / carbon composites is as follows:

[0084] (1) Take 250mL of hydrochloric acid with a concentration of 1mol / L, and cool down below 6°C in an ice-water bath;

[0085] (2) While stirring, add 32g of aniline, divided into four times, with an interval of 3-5 minutes each time, and can be added when the temperature is below 6°C;

[0086] (3) Add 1.7g of activated carbon, stir and disperse for 30 minutes, cool down to below 4°C in an ice-water bath, then add manganese dioxide (2.64g), and react for 15 minutes;

[0087] (4) Take another 150 mL of hydrochloric acid with a concentration of 1 mol / L, add 84 g of ammonium persulfate, and stir to dissolve;

[0088] (5) Under the condition of stirring, drop the ammonium persulfate in the form of dropwise addition, and control the dripping in about 2 hours;

[0089] (6) After the ammonium persulfate is added dropwise, continue to stir, and then...

Embodiment 3

[0094] Embodiment 3 (being comparative example 2)

[0095] The production process of polyaniline / carbon composites is as follows:

[0096] (1) Take 250mL of hydrochloric acid with a concentration of 1mol / L, and cool down below 6°C in an ice-water bath;

[0097] (2) While stirring, add 32g of aniline, divided into four times, with an interval of 3-5 minutes each time, and can be added when the temperature is below 6°C;

[0098] (3) Stir for 10 minutes, wait for the temperature to drop below 4°C, then add manganese dioxide (2.64g) and react for 15 minutes;

[0099] (4) Take another 150 mL of hydrochloric acid with a concentration of 1 mol / L, add 84 g of ammonium persulfate, and stir to dissolve;

[0100] (5) Under the condition of stirring, drop the ammonium persulfate in the form of dropwise addition, and control the dripping in about 2 hours;

[0101] (6) After the ammonium persulfate is added dropwise, continue to stir, react for 4 hours, and the temperature of the whole r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com