Solid foam profile control composition, solid foam profile control slurry, preparation method and profile control method thereof

A composition and foam technology, which is applied in the direction of drilling composition, chemical instruments and methods, and mining fluids, can solve the problems of short plugging validity period, general strength, and easy rupture, and achieve the expansion of steam sweeping volume and foaming The effect of large volume and good plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

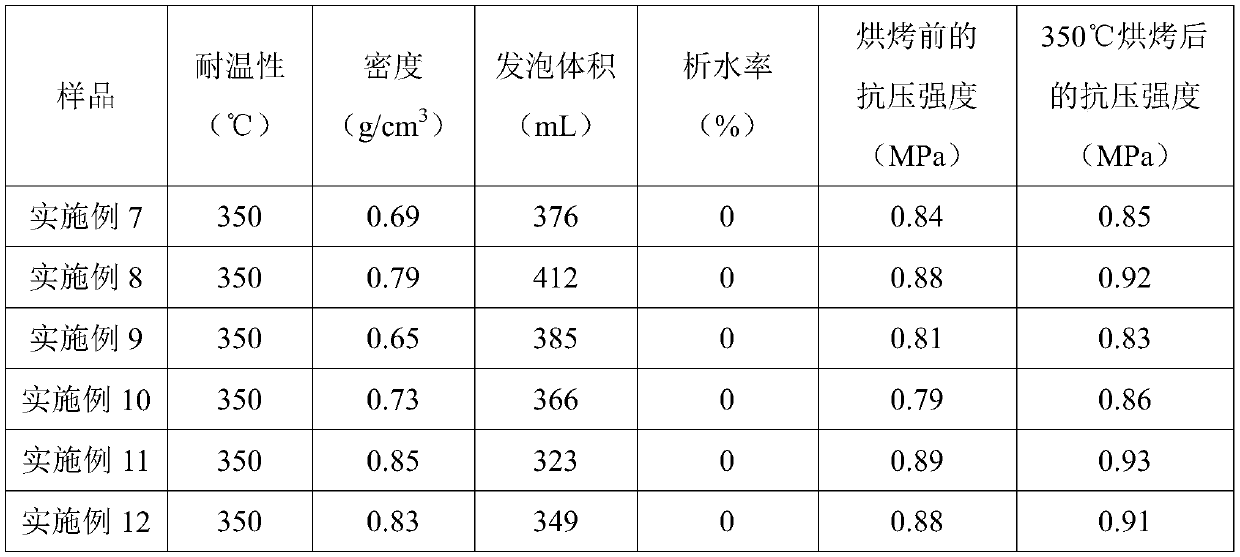

Examples

Embodiment 1

[0033] The solid foam profile control composition of the present embodiment is made up of the following raw materials in parts by weight: 10 parts of ultra-fine oil well cement (median particle size is 6 μm), 10 parts of sulphoaluminate cement, 5 parts of desulfurized gypsum powder, 0.2 Part lauryl amidopropyl betaine (Shanghai Minhao Fine Chemical Co., Ltd.), 0.2 part of alcohol ether carboxylate surfactant AEC-9Na (Qingdao Changxing Chemical Co., Ltd.), 0.2 part of xanthan gum, 1 part of white carbon black, 0.3 parts sodium gluconate.

Embodiment 2

[0035] The solid foam profile control composition of the present embodiment is made up of the following raw materials in parts by weight: 15 parts of ultra-fine oil well cement (median particle size is 3 μm), 5 parts of sulphoaluminate cement, 5 parts of desulfurized gypsum powder, 0.2 Part lauryl amidopropyl betaine (Shanghai Minhao Fine Chemical Co., Ltd.), 0.3 part of alcohol ether carboxylate surfactant AEC-9Na (Qingdao Changxing Chemical Co., Ltd.), 0.1 part of Wenlun glue, 3 parts of nanometer calcium carbonate, 0.2 parts boric acid.

Embodiment 3

[0037] The solid foam profile control composition of the present embodiment is composed of the following raw materials in parts by weight: 10 parts of ultra-fine oil well cement (particle size is 4 μm), 10 parts of sulphoaluminate cement, 3 parts of desulfurized gypsum powder, and 0.1 part of laurel Amidopropyl betaine (Shanghai Minhao Fine Chemical Co., Ltd.), 0.3 parts of alcohol ether carboxylate surfactant AEC-9Na (Qingdao Changxing Chemical Co., Ltd.), 0.1 part of Wenlun rubber, 2 parts of nanometer calcium carbonate, 0.3 part boric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com