Laboratory preparation method for CO2 foam fracturing fluid for coal-bed gas well and prepared foam fracturing fluid system

A foam fracturing fluid, coalbed methane well technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult evaluation of foam performance, immature foam preparation methods, etc., and achieves good foaming effect and heavy results. The effect of strong instantiation and sufficient foaming degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Coalbed methane well CO provided by the invention 2 The laboratory preparation method of foam fracturing fluid, the steps are as follows:

[0030] S1. Add foaming agent into distilled water, stir until completely dissolved, then add foam stabilizer, stir until completely dissolved to make base liquid.

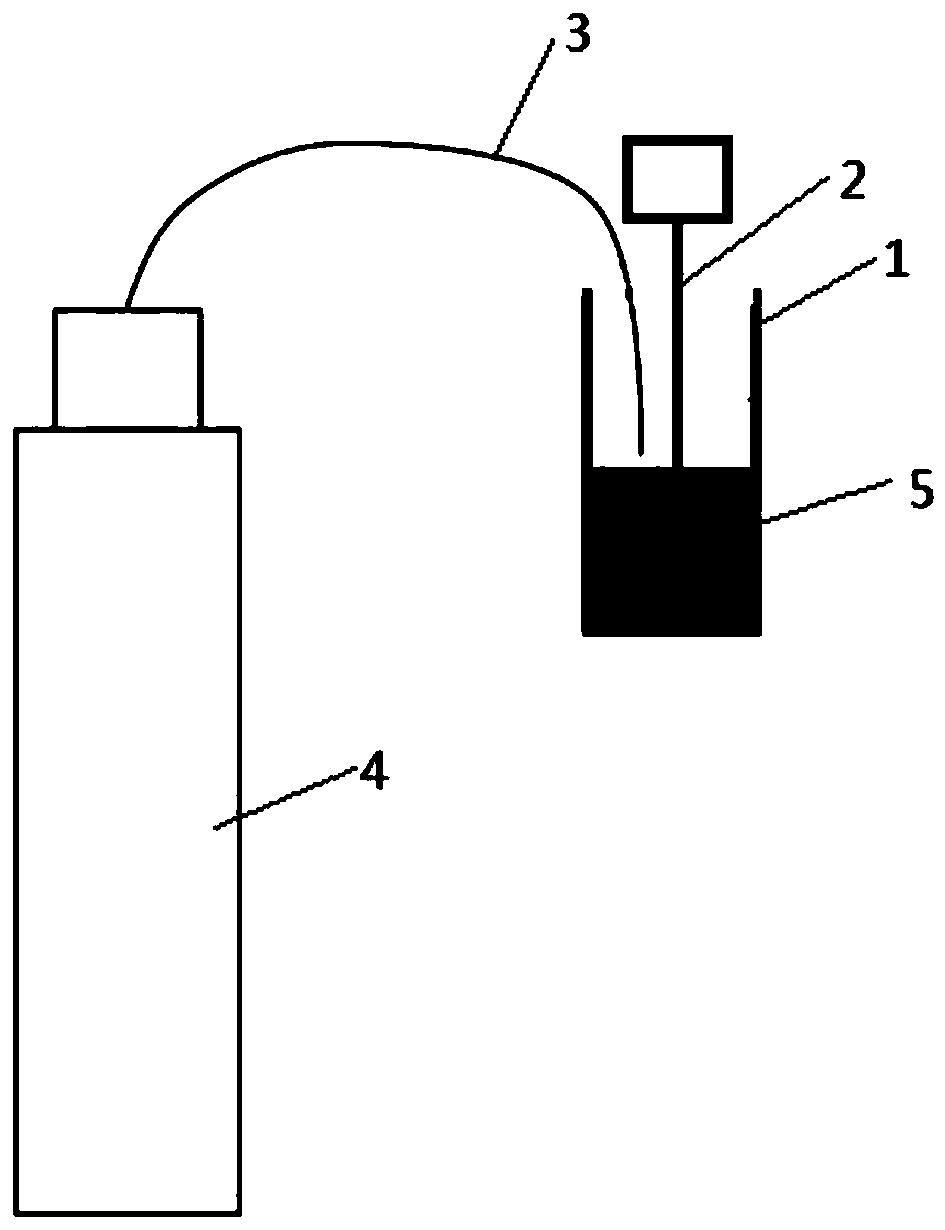

[0031] S2. Install the base liquid 5 in the foaming container 1, install the agitator 2 in the foaming container, and use a gas delivery hose 3, one end of which is connected to the liquid carbon dioxide storage tank 4, and the other end is inserted into the foaming container 1, For specific preparation equipment, see figure 1 .

[0032] S3. Insert the hose port below the base fluid level, and feed CO at 5L / min 2 Gas for 10 minutes, discharge the dissolved air in the base liquid, and increase CO 2 Solubility in foam base fluid.

[0033] S4. Lift the hose port to a position 1cm above the base liquid level, and feed CO at 10L / min 2 Gas for 5 minutes, remove the air i...

Embodiment 2

[0036] Coalbed methane well CO provided by the invention 2 The laboratory preparation method of foam fracturing fluid, the steps are as follows:

[0037] S1. Add foaming agent into distilled water, stir until completely dissolved, then add foam stabilizer, stir until completely dissolved to make base liquid.

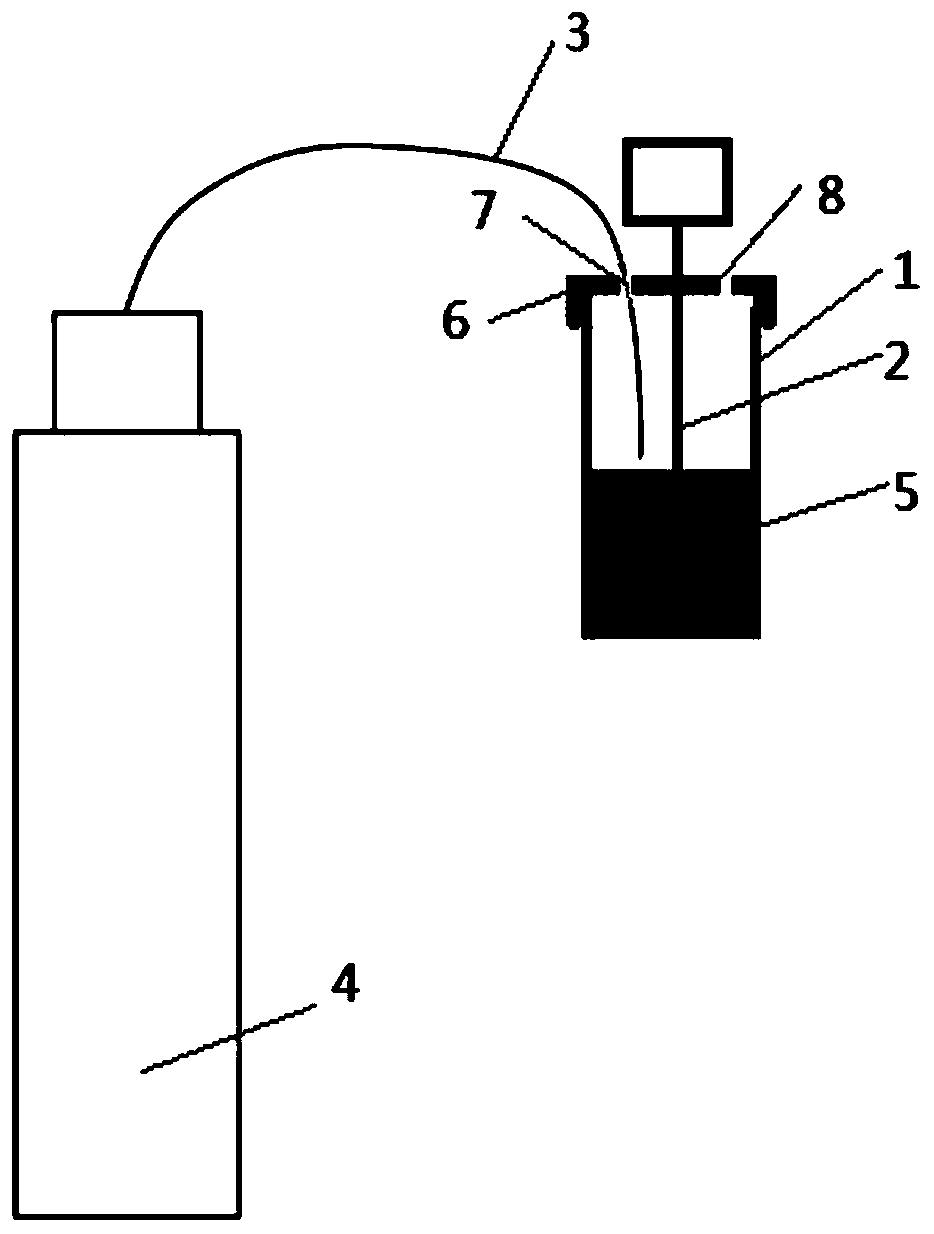

[0038] S2. Put the base liquid 5 in the foaming container 1, the foaming container has a sealed cover plate 6, and the agitator 2 is installed above the cover plate, and the stirring shaft of the agitator is inserted into the liquid in the foaming container from the center hole of the cover plate. Below the surface, an air inlet 7 and an air outlet 8 are respectively provided on the cover plate. One end of the hose 3 is inserted into the foaming container through the air inlet, and the other end of the hose is connected to the liquid carbon dioxide storage tank 4 . The air is removed from the air outlet, see the specific preparation device figure 1 .

[0039] S3. Inse...

Embodiment 3

[0043] A kind of coalbed methane well CO prepared according to the preparation method of embodiment 1 2 The foam fracturing fluid system includes a gas phase and a liquid phase, and the foam quality is 81.65%; the gas phase is carbon dioxide; based on the total weight of the liquid phase as 100%, the liquid phase includes the following components in weight percentage: 0.2% foaming agent dodecylbenzene Sodium sulfonate, 0.2% foam stabilizer sodium lauryl polyoxyethylene ether sulfate, and the balance is distilled water. This liquid phase is referred to as the base fluid.

[0044] Pour the prepared foam liquid into the graduated cylinder and press the stopwatch to count the time. The volume of the foam liquid in the graduated cylinder is 545ml at this time, and the calculated foam quality is 81.65%. When the volume of the precipitated liquid in the graduated cylinder reaches 50ml, count the reading of the stopwatch at this time For 5min plus 15s, the half-life is 315s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com