Cr-Si-Zr-B penetrant and application method thereof to surface of tantalum and tantalum alloy

An application method, tantalum alloy technology, applied to the surface of tantalum and tantalum alloys, in the field of Cr-Si-Zr-B penetrating agent, can solve problems such as blanks, and achieve the effects of convenient operation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

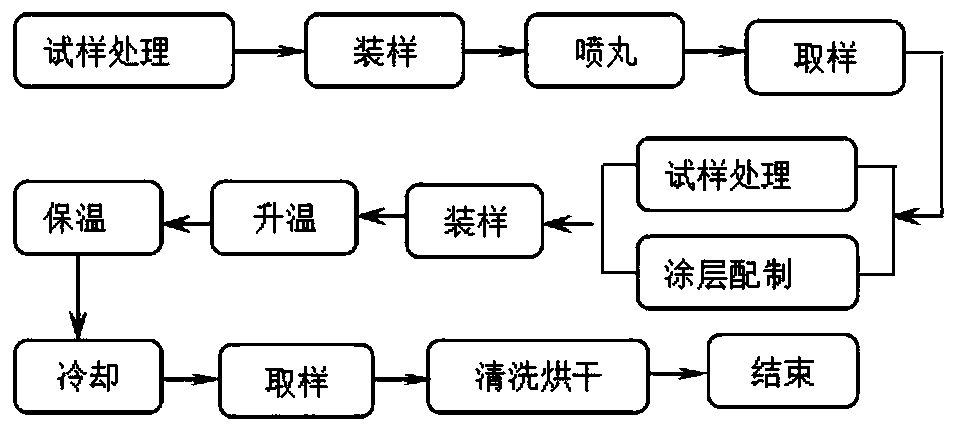

[0037] Such as figure 1 Said, a Cr-Si-Zr-B penetration agent on the surface of tantalum and tantalum alloy application method, including the following steps.

[0038] (1) Nano surface;

[0039] a. Place samples or workpieces of tantalum and tantalum alloys in the shot blasting chamber;

[0040] b. Mechanical vibration shot peening: projectile diameter 6mm, mechanical vibration frequency 50Hz, distance between projectile and sample 16mm, shot peening time 90min;

[0041] c. Rinse the shot peened samples or workpieces with running water, then dry them for later use.

[0042] (2) Embedding infiltration Cr-Si-Zr-B coating;

[0043] a. Washing: Rinse the sample or workpiece with flowing water and dry it;

[0044] b. Preparation of osmotic agent: accurately weigh the osmotic agent according to the amount, and the proportioning of Cr-Si-Zr-B osmotic agent is by weight percentage: 9% Cr powder, 7% Si powder, 2.5% Zr powder, 1.3% B powder , 5.5% NaF (analytically pure), 1.5% NH 4...

Embodiment 2

[0052] Such as figure 1 As shown, a method for applying a Cr-Si-Zr-B infiltration agent on the surface of tantalum and tantalum alloys includes the following steps.

[0053] (1) Nano surface;

[0054] a. Place the sample or workpiece in the shot blasting chamber;

[0055] b. Mechanical vibration shot peening: projectile diameter 5mm, mechanical vibration frequency 50Hz, distance between projectile and sample 15mm, shot peening time 80min;

[0056] c. Rinse the shot peened samples or workpieces with running water, then dry them for later use.

[0057] (2) Embedding infiltration Cr-Si-Zr-B coating;

[0058] a. Washing: Rinse the sample or workpiece with flowing water and dry it;

[0059] b. Preparation of osmotic agent: accurately weigh the osmotic agent according to the amount, and the proportioning of Cr-Si-Zr-B osmotic agent is by weight percentage: 8% Cr powder, 6% Si powder, 2% Zr powder, 1.2% B powder , 5% NaF (analytically pure), 1% NH 4 Cl (analytical pure), the re...

Embodiment 3

[0067] Such as figure 1 As shown, a method for applying a Cr-Si-Zr-B infiltration agent on the surface of tantalum and tantalum alloys includes the following steps.

[0068] (1) Nano surface;

[0069] a. Place the sample or workpiece in the shot blasting chamber;

[0070] b. Mechanical vibration shot peening: projectile diameter 7mm, mechanical vibration frequency 50Hz, distance between projectile and sample 17mm, shot peening time 100min;

[0071] c. Rinse the shot peened samples or workpieces with running water, then dry them for later use.

[0072] (2) Embedding infiltration Cr-Si-Zr-B coating;

[0073] a. Washing: Rinse the sample or workpiece with flowing water and dry it;

[0074] b. Preparation of osmotic agent: accurately weigh the osmotic agent according to the amount, and the proportioning of Cr-Si-Zr-B osmotic agent is by weight percentage: 10% Cr powder, 8% Si powder, 3% Zr powder, 1.5% B powder , 6% NaF (analytical grade), 2% NH 4 Cl (analytical pure), the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com