Antibacterial fabric and production method thereof

A technology of antibacterial fabrics and production methods, applied in dyeing, biochemical fiber treatment, yarn, etc., can solve the problems of low comfort, inconspicuous antibacterial effect, poor antibacterial effect, etc., and achieve yarn breathability, soft hand feeling, super Strong abrasion resistance and moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An antibacterial fabric comprises 70 wool and 30 polyester by weight; the yarn count of the fabric is 20 / 2Nm, and the ply twist is 180 twists / m.

[0051] A production method of an antibacterial fabric, comprising the following steps:

[0052] 1) Raw material selection:

[0053] Use wool fibers and polyester fibers with uniform fineness and length as raw materials;

[0054] 2) Dyeing process

[0055] Dyeing wool and polyester with environmentally friendly reactive dyes;

[0056] 3) Antibacterial treatment process

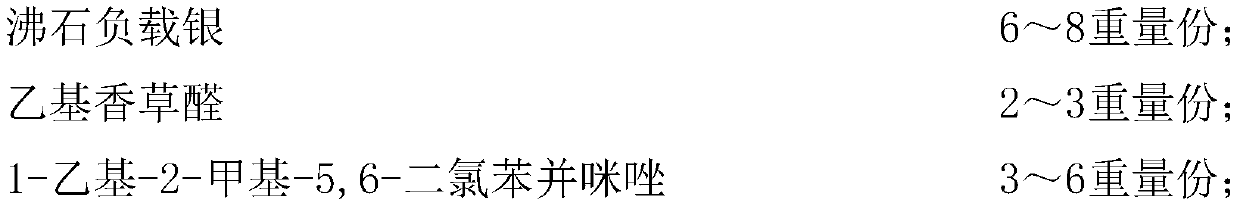

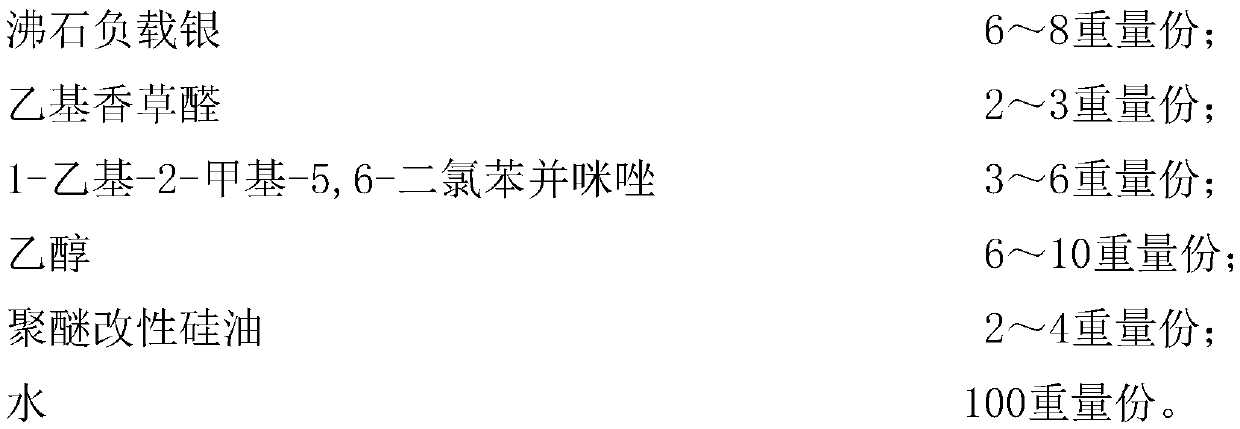

[0057] Add wool and polyester to the antibacterial finishing solution for antibacterial treatment;

[0058] 4) Spinning process

[0059] Mixed sliver - roving - spun yarn - winding - finished product.

[0060]Dyeing at 80°C, keep warm for 40 minutes; the dyeing temperature is 20°C, and the heating rate is 1°C / 1.5min during dyeing; add environmentally friendly and crude oil in the mixing step, the oil content is 0.6%, and the water temperature is controll...

Embodiment 2

[0065] An antibacterial fabric comprises 75 wool and 25 polyester by weight.

[0066] The yarn count of the fabric is 18 / 2Nm, and the ply twist is 180 twists / m.

[0067] A production method of an antibacterial fabric, comprising the following steps:

[0068] 1) Raw material selection:

[0069] Use wool fibers and polyester fibers with uniform fineness and length as raw materials;

[0070] 2) Dyeing process

[0071] Dyeing wool and polyester with environmentally friendly reactive dyes;

[0072] 3) Antibacterial treatment process

[0073] Add wool and polyester to the antibacterial finishing solution for antibacterial treatment;

[0074] 4) Spinning process

[0075] Mixed sliver - roving - spun yarn - winding - finished product.

[0076] Dyeing at 85°C, heat preservation for 60 minutes; dyeing temperature is 20°C, heating rate is 1°C / 1.5min during dyeing; environmental protection and crude oil are added in the mixing step, the oil content is 0.7%; spinning speed is 7200 r...

Embodiment 3

[0080] An antibacterial fabric comprises 80 wool and 20 polyester by weight.

[0081] The yarn count of the fabric is 20 / 2Nm, and the ply twist is 180 twists / m.

[0082] A production method of an antibacterial fabric, comprising the following steps:

[0083] 1) Raw material selection:

[0084] Use wool fibers and polyester fibers with uniform fineness and length as raw materials;

[0085] 2) Dyeing process

[0086] Dyeing wool and polyester with environmentally friendly reactive dyes;

[0087] 3) Antibacterial treatment process

[0088] Add wool and polyester to the antibacterial finishing solution for antibacterial treatment;

[0089] 4) Spinning process

[0090] Mixed sliver - roving - spun yarn - winding - finished product.

[0091] Dye at 90°C and keep warm for 80 minutes; the starting temperature of the dyeing is 20°C, and the heating rate is 1°C / 1.5min during dyeing; add environmental-friendly and crude oil in the mixing step, and the oil content is 0.8%; the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com