Preparation method of fermented mulberry fruit wine

A mulberry fruit and fermentation type technology, applied in the field of fruit wine processing, can solve problems such as taste, color difference, etc., and achieve the effect of sweet and sour entrance, rich color and unique aroma of mulberry fruit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, the preparation method of mulberry fruit wine

[0015] (1) The fresh and mature local variety Qiangeli mulberry (purple black mulberry) is selected as the raw material for wine making, and it is harvested from Turpan, Xinjiang. Wash clean; remove bad fruit and crush at low temperature. Weigh 7kg of mulberries in a 10L glass wide-mouth fermenter, press to break, and add 148.1mg / kg of potassium metabisulfite solution (sulfur dioxide concentration is equivalent to 80mg / kg) dropwise during the breaking process for color protection and sterilization. Potassium sulfate was dissolved in 10x sterile water before adding. Add pectinase 20mg / kg, hydrolyze at room temperature (20-30°C) for 8 hours; (2) Yeast activation: choose low temperature resistant yeast LABA, add active dry yeast at 0.22mg / kg, first add active dry yeast 10 times 5% of the volume, in (35±1)°C sugar solution, put it in (35±1)°C constant temperature water bath, stir gently, wait for the yeast to a...

Embodiment 2

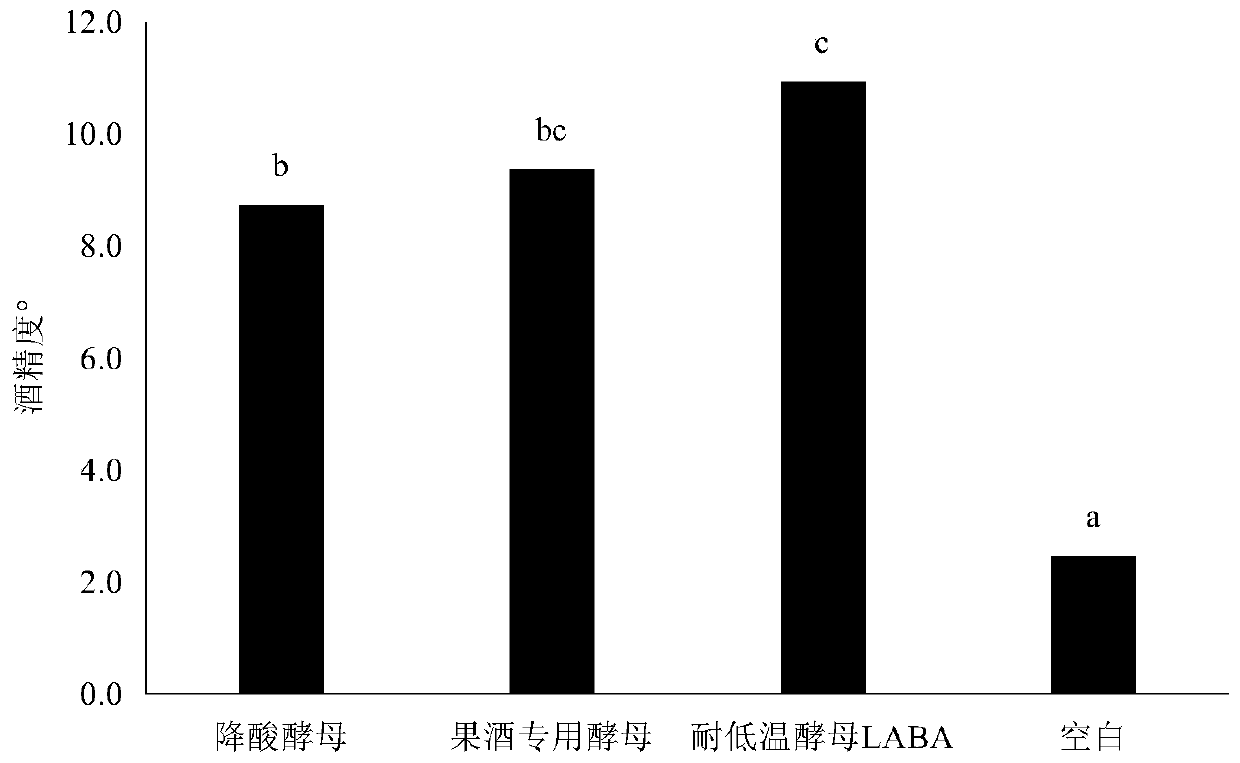

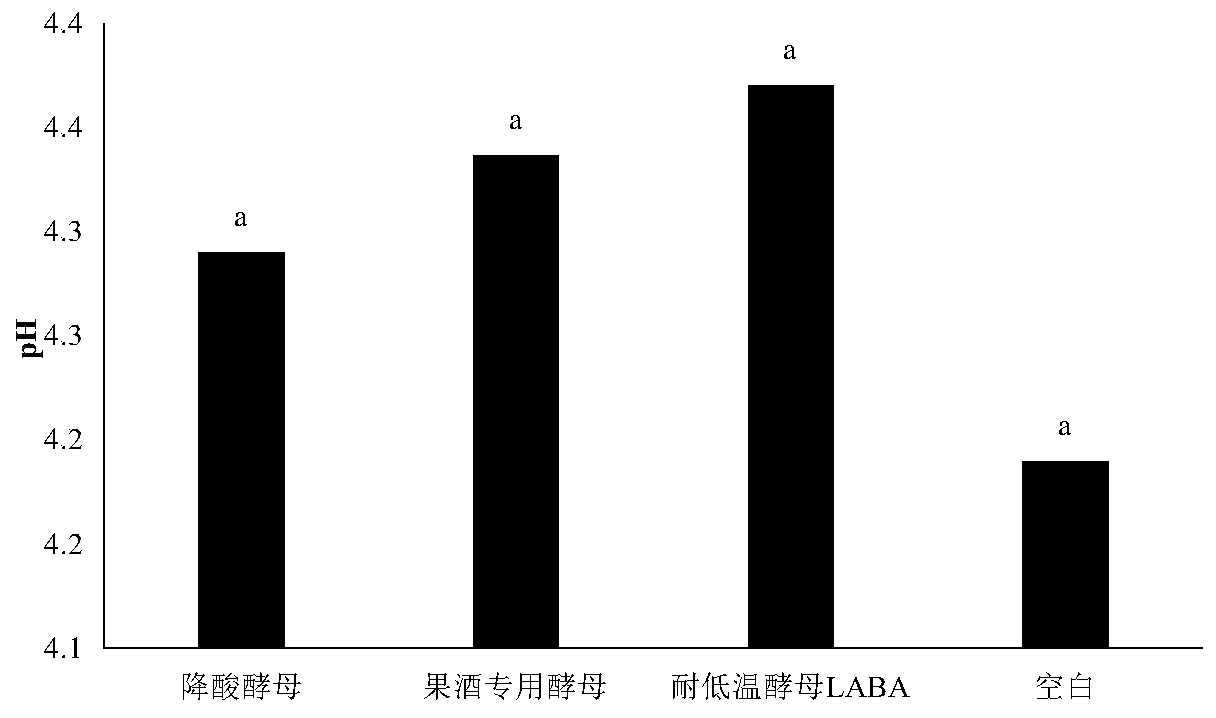

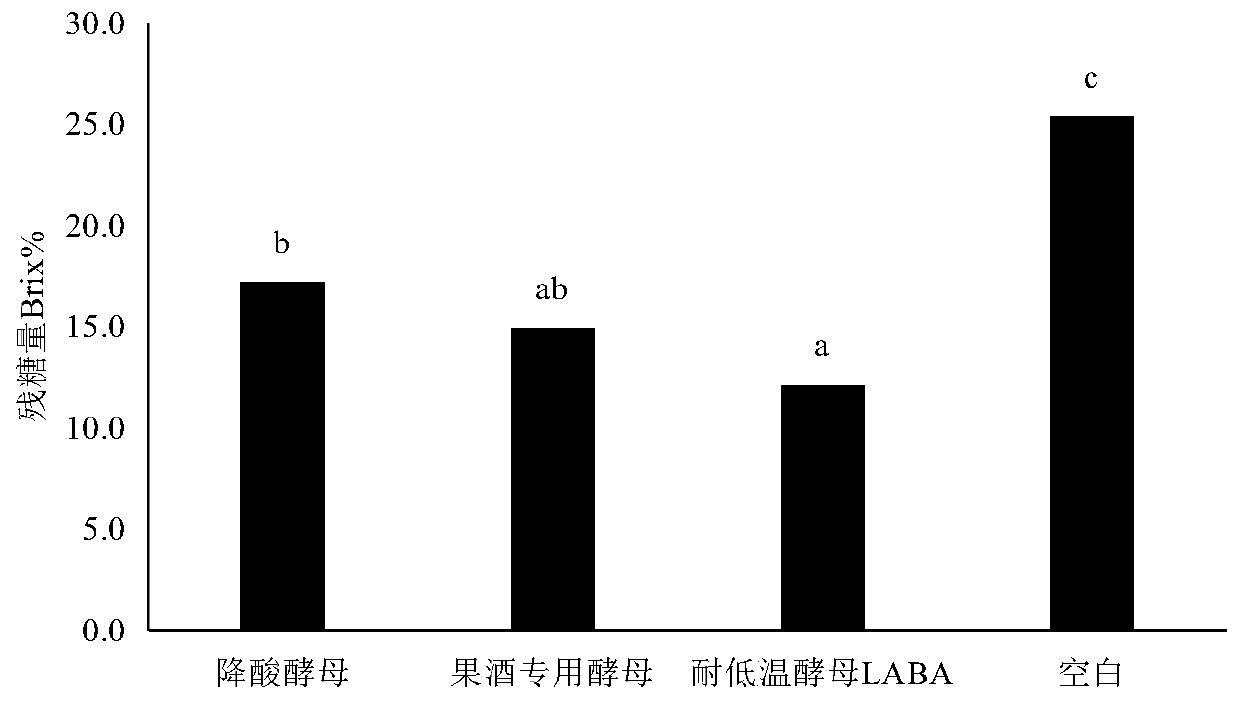

[0016] Embodiment 2, determination of the best mulberry fruit wine brewing yeast variety

[0017] (1) The fresh and mature local variety Qiangeli mulberry (purple black mulberry) is selected as the raw material for wine making, and it is harvested from Turpan, Xinjiang. Wash clean; remove bad fruit and crush at low temperature. Prepare 9 parts of 7kg mulberry fruit, put them in 10L glass wide-mouth fermenter, press and crush, add 92.5mg / kg potassium metabisulfite solution (sulfur dioxide concentration is equivalent to 50mg / kg) dropwise during the crushing process for color protection and sterilization , Dissolve in 10x sterile water before adding potassium metabisulfite. Add 20 mg / kg of pectinase, enzymolysis at room temperature (20-30°C) for 8 hours; (2) Yeast activation: first add 10 times the volume of active dry yeast to 5% sugar solution at (35±1)°C, place Stir gently in a constant temperature water bath at (35±1)°C. After the yeast is activated for 15 minutes, a layer ...

Embodiment 3

[0020] Embodiment 3, the determination of optimum mulberry fruit wine brewing yeast inoculation amount

[0021] (1) The fresh and mature local variety Qiangeli mulberry (purple black mulberry) is selected as the raw material for wine making, and it is harvested from Turpan, Xinjiang. Wash clean; remove bad fruit and crush at low temperature. Prepare 9 parts of 7kg mulberry fruit, put them in 10L glass wide-mouth fermenter, press and crush, add 92.5mg / kg potassium metabisulfite solution (sulfur dioxide concentration is equivalent to 50mg / kg) dropwise during the crushing process for color protection and sterilization , Dissolve in 10x sterile water before adding potassium metabisulfite. Add 20 mg / kg of pectinase, enzymolysis at room temperature (20-30°C) for 8 hours; (2) Yeast activation: first add 10 times the volume of active dry yeast to 5% sugar solution at (35±1)°C, place Stir gently in a constant temperature water bath at (35±1)°C. After the yeast is activated for 15 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com