Method for repairing lead-chromium composite contaminated soil by combining humic acid and sudangrass

A chromium-contaminated soil and joint restoration technology is applied in the field of joint restoration of lead-chromium-contaminated soil with humic acid and sudan grass, which can solve the problems of compound pollution and difficult survival of plants, and improve soil and promote crop growth with a simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

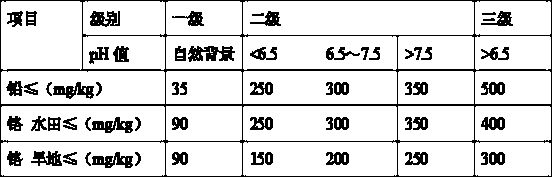

Embodiment 1

[0010] The present invention is a method for jointly repairing lead-chromium-contaminated soil by using humic acid and sudan grass. Humic acid is evenly sprinkled on the surface layer of lead-chromium-contaminated soil at a rate of 150 kg / mu. The soil surface layer contains 275.4 mg / kg of chromium and 989.7 mg / kg of lead. , plow the soil to a depth of 20cm, rake and divide the ridges, and the row spacing between the ridges is 35cm. After 7 days, sow sudan grass seeds evenly in each ridge. The sowing rate is 1.8kg / mu, and the sowing depth is 3cm. During the process, water once every 4-6 days, and manage according to the normal growth requirements of Sudan grass. After 30 days of growth of Sudan grass, soil samples were collected for measurement. The soil lead content was ≤218mg / kg, and the chromium content was ≤95mg / kg, meeting the requirements of national environmental standards. , to achieve the remediation of lead and chromium contaminated soil.

Embodiment 2

[0012] The present invention is a method for jointly repairing lead-chromium-contaminated soil by using humic acid and sudan grass. Humic acid is evenly sprinkled on the surface layer of lead-chromium-contaminated soil at a rate of 110kg / mu. kg, plow the soil to a depth of 21cm, rake it flat, divide the ridges, and the row spacing between the ridges is 38cm. After 7 days, sow sudan grass seeds evenly in each ridge. The sowing rate is 1.6kg / mu, and the sowing depth is 2.8cm. Water once every 4-5 days during the plant growth process, and manage according to the normal growth requirements of Sudan grass. After the Sudan grass grows for 30 days, soil samples are collected for measurement. The soil lead content is ≤218mg / kg, and the chromium content is ≤95mg / kg, which meets the national environmental requirements. Standard requirements, to achieve the remediation of lead and chromium contaminated soil.

Embodiment 3

[0014] The present invention is a method for jointly repairing lead-chromium-contaminated soil by using humic acid and sudan grass. Humic acid is evenly sprinkled on the surface layer of lead-chromium-contaminated soil at a rate of 180kg / mu. kg, plow the soil to a depth of 19cm, rake it flat, divide the ridges, and the row spacing between the ridges is 32cm. After 7 days, sow sudan grass seeds evenly in each ridge. The sowing rate is 1.9kg / mu, and the sowing depth is 3.2cm. Water once every 6-7 days during plant growth, and manage according to the normal growth requirements of Sudan grass. After 30 days of growth of Sudan grass, soil samples are collected for measurement. The soil lead content is ≤218mg / kg, and the chromium content is ≤95mg / kg, which meets the national environmental requirements. Standard requirements, to achieve the remediation of lead and chromium contaminated soil.

[0015] The present invention is through on-the-spot test and test, and effect is very good,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com