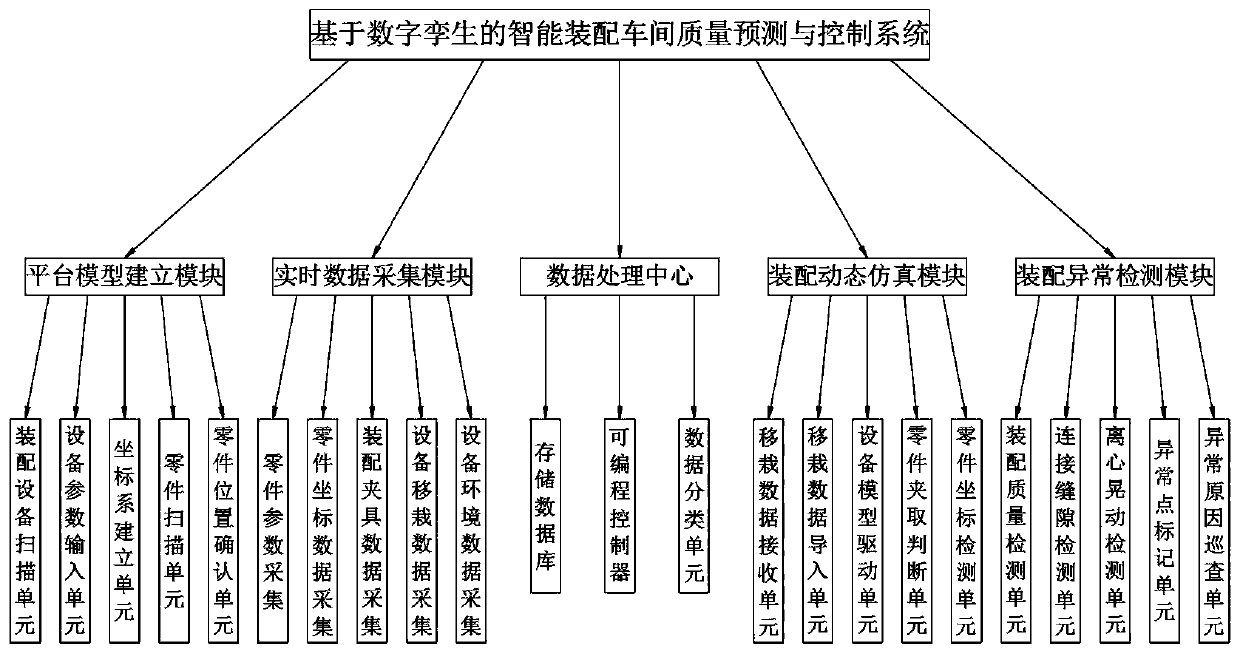

Intelligent assembly workshop quality prediction and control system and method based on digital twinning

A quality prediction, assembly workshop technology, applied in the field of digital twins, can solve the problems of manual abnormal inspection of assembly equipment, waste of human, material and financial resources, affecting the efficiency of parts assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

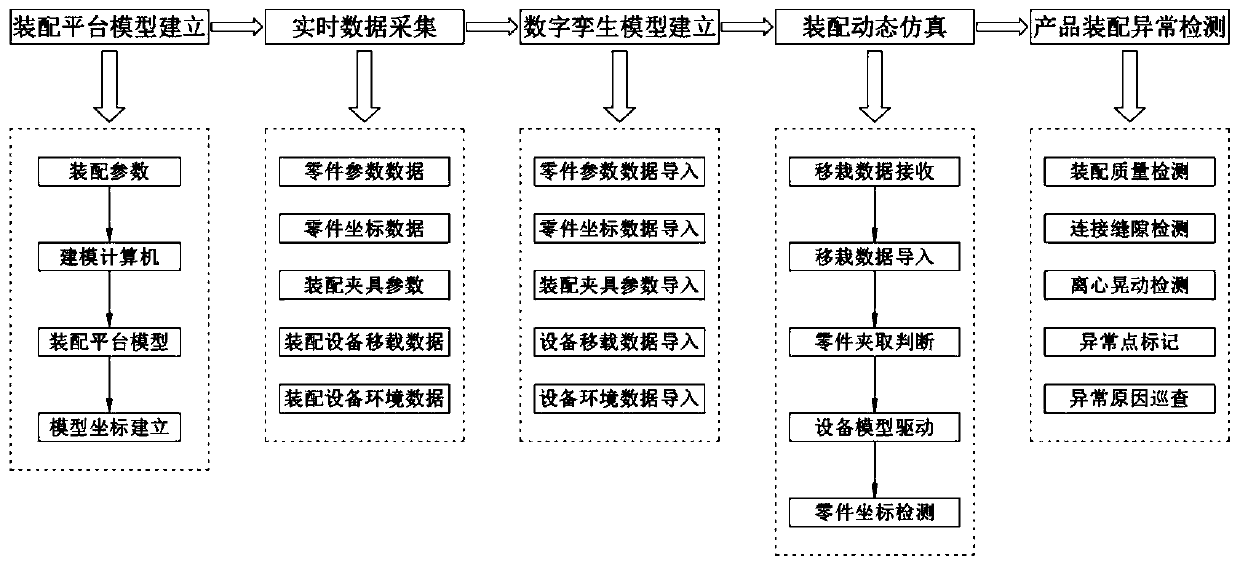

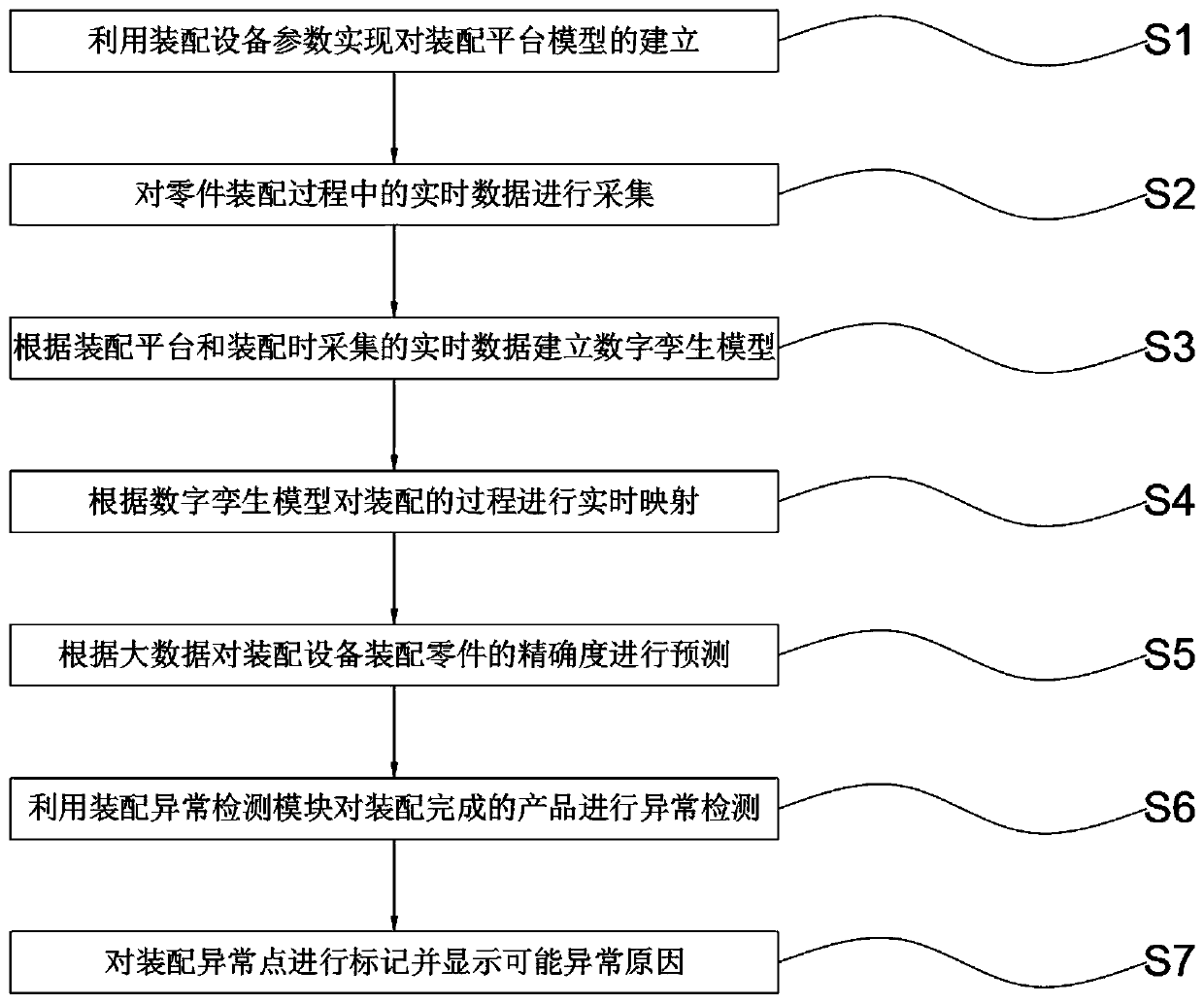

Method used

Image

Examples

Embodiment 1

[0114] Use the assembly equipment scanning unit to scan the assembly equipment in three dimensions. The assembly equipment scanning unit may be a three-dimensional scanner. Scan the data to establish a static model of the assembly platform, use the equipment parameter input unit to input the parameter information of the assembly equipment, the parameter information includes information such as transplanting speed, transplanting angle range, motor speed and power, etc., use the coordinate establishment unit to establish A three-dimensional coordinate system (X, Y, Z) is established on the static model of the assembly platform as the positioning standard for the transplanting data of the assembly equipment and the transplanting parts of the parts. The part scanning unit performs three-dimensional scanning on the parts to be assembled to obtain the Three-dimensional data, importing the three-dimensional data of the part into the modeling computer, confirming the three-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com