Pretreatment method of 2-alkylanthraquinone working solution and production method of hydrogen peroxide

An alkyl anthraquinone, pretreatment technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of 2-alkyl Anthraquinone working solution contains impurities, which affects process operation and product indicators, etc., to achieve good industrial application prospects, solve poisoning and inactivation, reduce impurities and sulfur content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

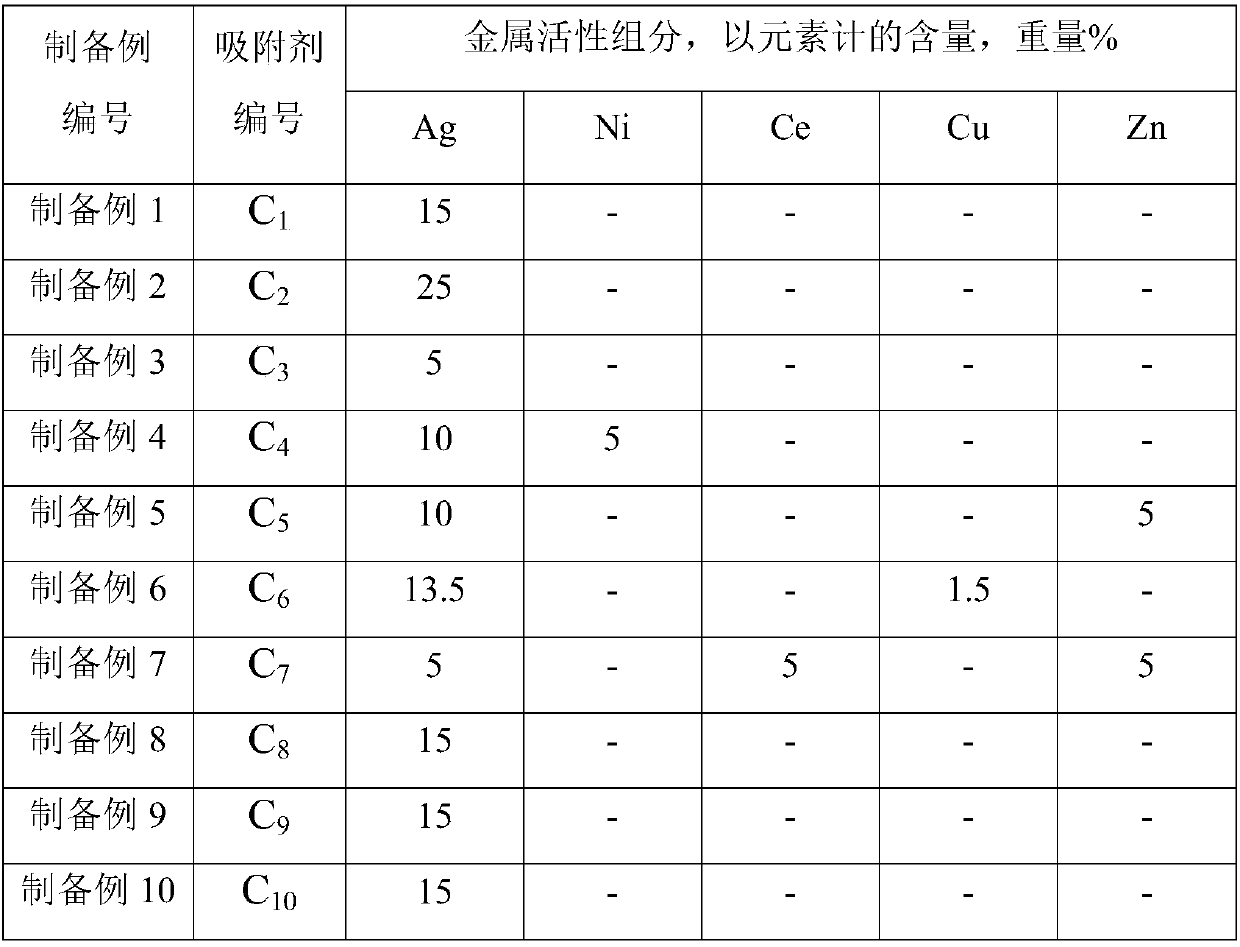

[0026]According to the present invention, except that the composition of the adsorbent is selected according to the present invention, the preparation method of the adsorbent can refer to conventional methods in the art. For example, any one of impregnation method, precipitation method, blending method, ion exchange method, roll coating method and spray coating method can be used to introduce the transition metal active component onto the carrier. Preferably, the present invention adopts an impregnation method to prepare the adsorbent. The present invention has no special requirements for the impregnation method, and can be various impregnation methods in the prior art, such as selecting a dry impregnation method (i.e. equal volume impregnation method). Preparation, can also choose such as incipient wetness impregnation method for impregnation preparation. According to a specific embodiment of the present invention, the preparation method of the adsorbent includes: contacting ...

preparation example 1

[0071] This preparation example is used to illustrate the preparation of the adsorbent.

[0072] Take 100 grams of gamma alumina carrier, impregnate the carrier with 60 ml of an aqueous solution containing 23.61 grams of silver nitrate for 24 hours, filter, dry the solid at 120°C for 6 hours, and roast at 500°C for 4 hours to prepare adsorbent C 1 . The composition of the adsorbent is shown in Table 1.

preparation example 2

[0074] This preparation example is used to illustrate the preparation of the adsorbent.

[0075] The adsorbent was prepared according to the method of Preparation Example 1, except that the carrier was impregnated with 60 milliliters of an aqueous solution containing 39.35 grams of silver nitrate for 24 hours to obtain adsorbent C 2 . The composition of the adsorbent is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com