A carbon/carbon composite material surface functional coating and preparation method thereof

A carbon composite material and functional technology, applied in the field of inorganic materials, can solve the problems of high-efficiency and thin-layer electromagnetic functional coatings that are difficult to be compatible and fall off, and achieve the effect of improving electromagnetic functional characteristics, improving service performance, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

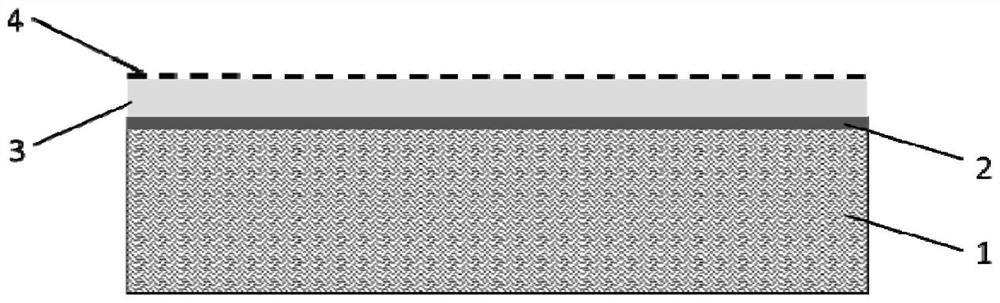

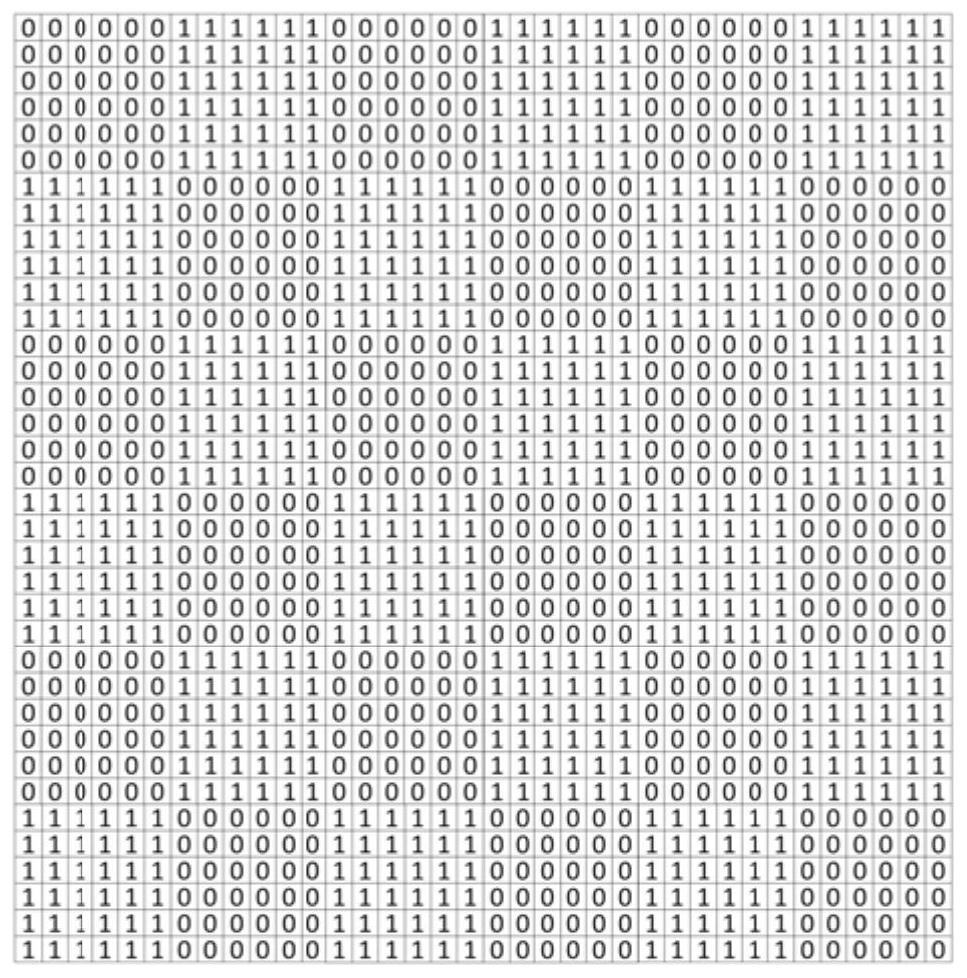

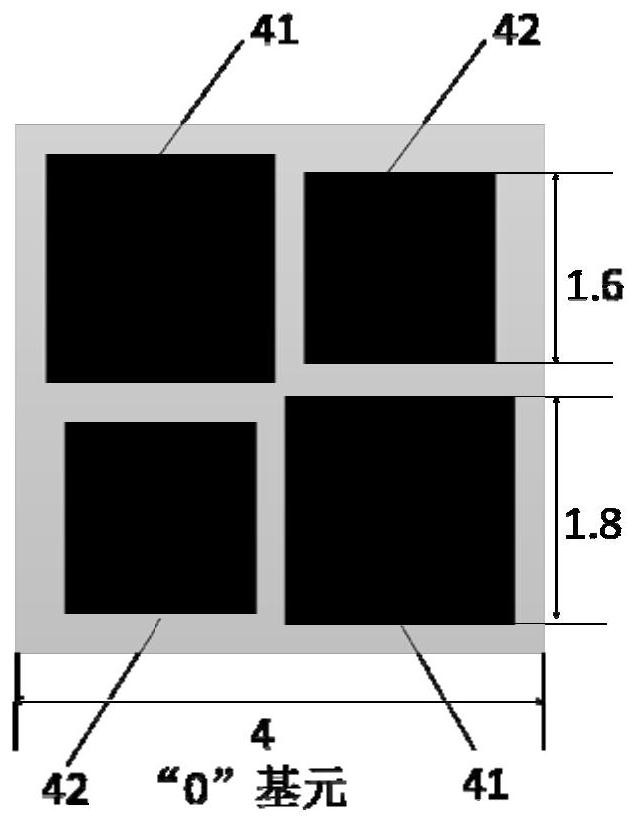

Embodiment 1

[0046] In this embodiment, the transition bonding layer 2 is a C-SiC transition bonding layer with a thickness of 0.1 mm; the anti-oxidation structure layer 3 is Al 2 o 3 The anti-oxidation structural layer has a thickness of 0.8mm; the material of the electromagnetic functional block is mainly Ag-Pd alloy, and the thickness is 0.08mm. Each electromagnetic functional block is arranged periodically according to the above to form a pattern of two checkerboard units interlaced, such as figure 2 As shown, the space ratio of the checkerboard unit is 1, and each checkerboard unit contains a 6×6 primitive sequence (the primitive sequence refers to a 0 primitive pattern or a 1 primitive pattern), and the side length of the square grid unit is 4mm , in the 0 primitive pattern, the side lengths of the first 0 primitive block 41 and the second 0 primitive block 42 are 1.8mm and 1.6mm respectively, in the 1 primitive pattern, the first 1 primitive block 43 and the second 1 The side len...

Embodiment 2

[0053] In this embodiment, the transition bonding layer 2 is C-SiC-ZrC-ZrSi 2 The transition bonding layer has a thickness of 0.1 mm; the anti-oxidation structure layer 3 is an MAS anti-oxidation structure layer, and its thickness is 1 mm; the material of the electromagnetic functional block is mainly Mo-Si alloy, and its thickness is 0.02 mm. Each electromagnetic functional block is arranged periodically according to the above to form a pattern of two checkerboard units interlaced. The space ratio of the checkerboard unit is 1, and each checkerboard unit contains a 6×6 primitive sequence (the primitive sequence refers to a 0 primitive pattern or 1 primitive pattern), the side length of the square grid unit is 5mm, in the 0 primitive pattern, the side lengths of the first 0 primitive block 41 and the second 0 primitive block 42 are 2.2mm and 2mm respectively, and the 1 primitive In the element pattern, the side lengths of the first 1-unit block 43 and the second 1-unit block 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com