A method and device for sticking film on lithium battery

A lithium battery and film sticking technology, which is applied in the field of lithium battery sticking film equipment, can solve the problems of inconvenience in feeding and discharging materials of lithium batteries, and achieve the effects of ensuring orderliness and continuity, reducing equipment occupied space and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

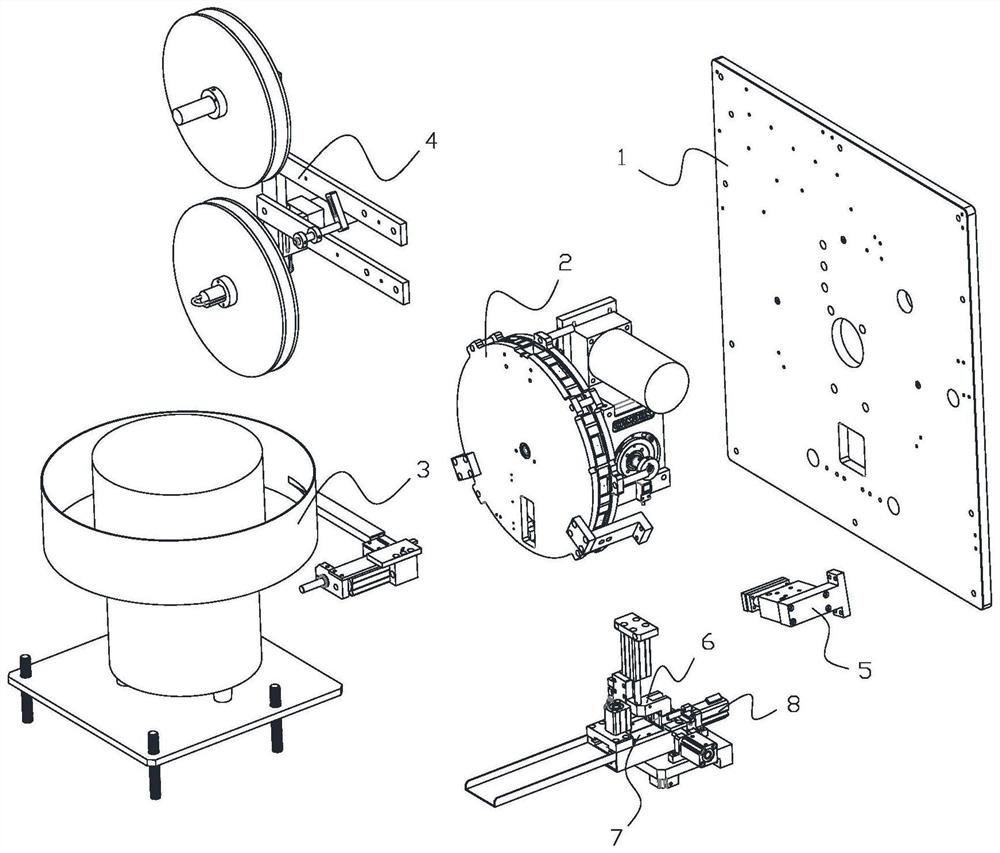

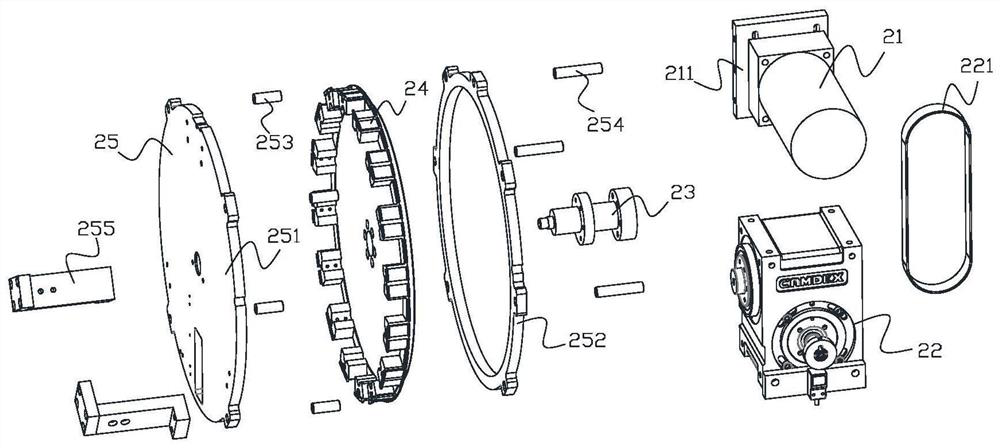

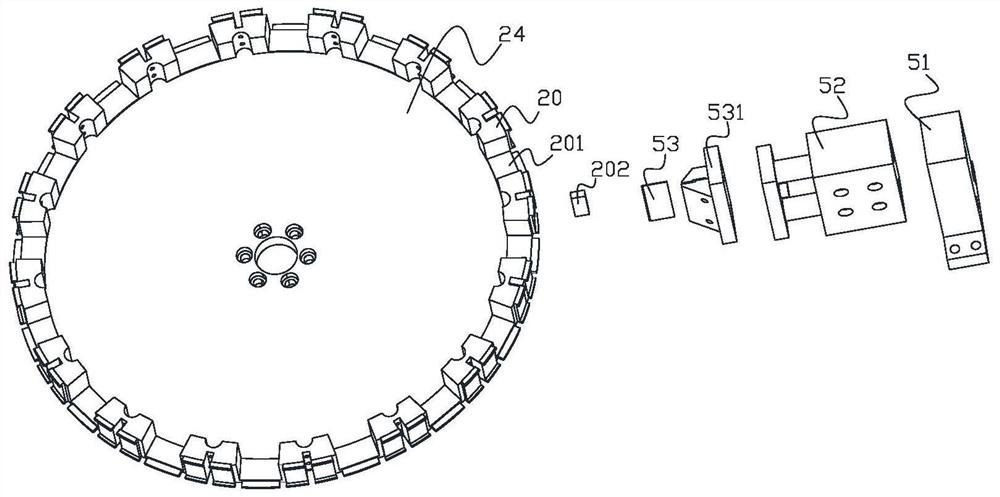

[0031] like figure 1 As shown, a lithium battery film sticking equipment, the equipment includes a vertical plate 1, a conveying device 2, a lithium battery feeding device 3, a film retracting device 4, a cutting device 5, a feeding device 6, and a back bonding device 7 And discharge device 8. Riser 1 is vertically arranged. The conveying device 2 is vertically arranged in the middle of the vertical plate 1. The conveying device 2 is a turntable structure. The jigs 20 on the conveying device 2 are evenly distributed in the circumferential direction. The conveying device 2 sends the lithium battery from the feed end to the discharge through the jigs 20 At the end, the turntable structure effectively reduces the space occupied by the equipment, and the recycling of 20 fixtures improves the loading and unloading speed of lithium batteries. The lithium battery feeding device 3 is arranged at the feeding end of the conveying device 2, and the lithium battery feeding device 3 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com