A preparation method of co-heating multiple monomers for thermal battery

A thermal battery and monomer technology, applied in the direction of delayed action cells, etc., can solve problems such as the use of ultra-thin single chips, high heat, and reduced mechanical strength, so as to optimize the structure of thermal battery cells and avoid thermal mismatch , Improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

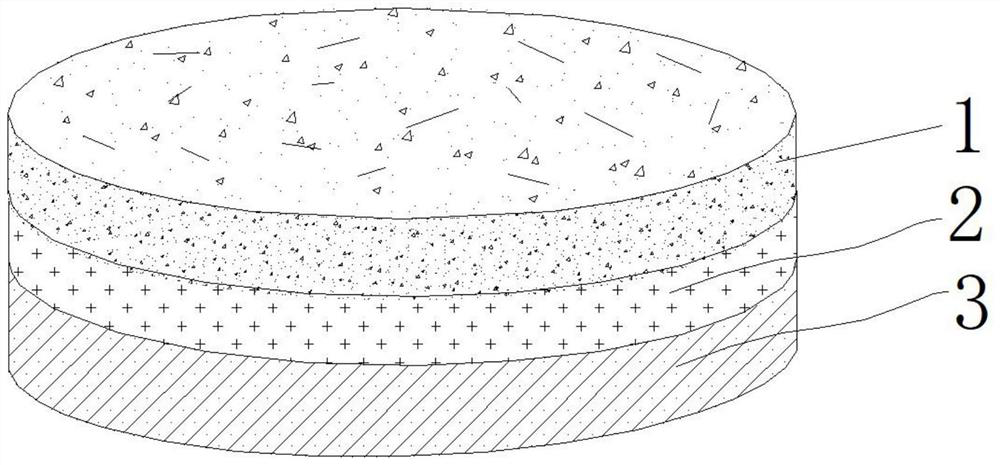

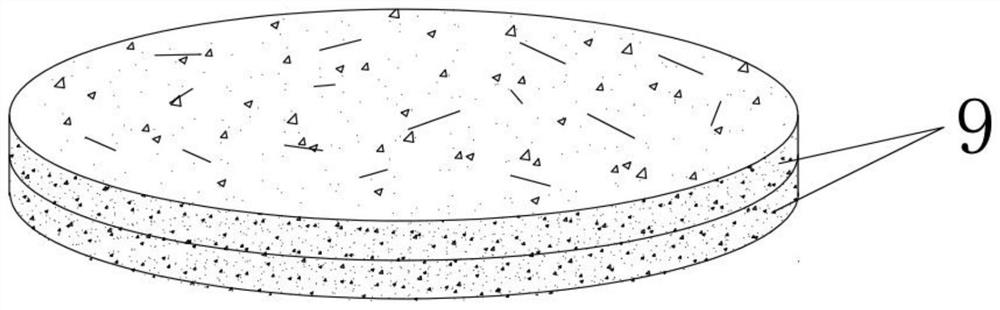

[0038] Such as figure 1 , figure 2 As shown, a preparation method of co-heating multi-monomer for thermal battery, said co-heating multi-monomer is composed of multi-monomer layer (1), buffer layer (2) and heating layer (3), the co-heating multi-monomer The preparation method of the monomer includes the preparation of a heating sheet, a buffer heating sheet, positive and negative electrodes, a separator and a co-heating multi-monomer, specifically including the following steps;

[0039] ①Preparation of the heating sheet: Pour the heating powder of the thermal battery into the mold, apply a pressure of 10KN to form the heating sheet (8); the diameter of the groove of the mold is 8mm;

[0040] ②Preparation of the buffer heating sheet: spray a conductive adhesive on the surface of the heating sheet (8) prepared in step ①, and then stick the buffer layer (2) on the surface of the heating sheet (8) to obtain a buffer heating sheet;

[0041] The buffer layer (2) is a graphite sub...

Embodiment 2

[0048] Such as figure 1 , image 3 As shown, a preparation method of co-heating multi-monomer for thermal battery, said co-heating multi-monomer is composed of multi-monomer layer (1), buffer layer (2) and heating layer (3), the co-heating multi-monomer The preparation method of the monomer includes the preparation of a heating sheet, a buffer heating sheet, positive and negative electrodes, a separator and a co-heating multi-monomer, specifically including the following steps;

[0049] ①Preparation of the heating sheet: Pour the heating powder of the thermal battery into the mold, apply a pressure of 1200KN to form the heating sheet (8); the diameter of the groove of the mold is 130mm;

[0050] ②Preparation of the buffer heating sheet: spray a conductive adhesive on the surface of the heating sheet (8) prepared in step ①, and then stick the buffer layer (2) on the surface of the heating sheet (8) to obtain a buffer heating sheet;

[0051] The buffer layer (2) is a high ther...

Embodiment 3

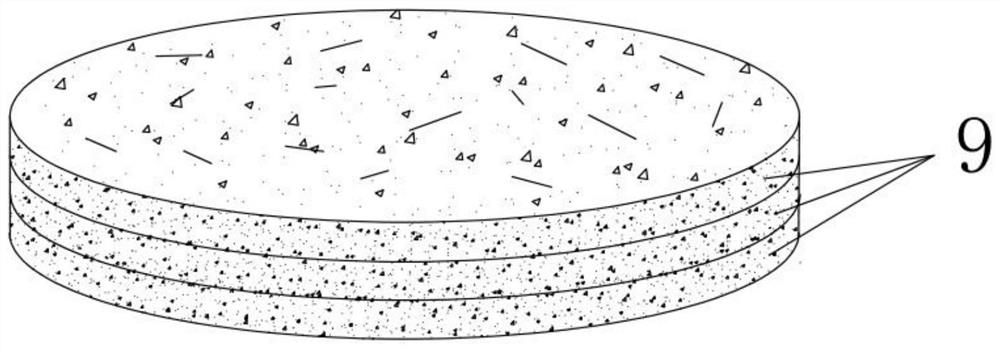

[0058] Such as figure 1 , Figure 4 As shown, a preparation method of co-heating multi-monomer for thermal battery, said co-heating multi-monomer is composed of multi-monomer layer (1), buffer layer (2) and heating layer (3), the co-heating multi-monomer The preparation method of the monomer includes the preparation of a heating sheet, a buffer heating sheet, positive and negative electrodes, a separator and a co-heating multi-monomer, specifically including the following steps;

[0059] ①Preparation of the heating sheet: Pour the heating powder of the thermal battery into the mold, apply a pressure of 560KN to form the heating sheet (8); the diameter of the groove of the mold is 60mm;

[0060] ②Preparation of the buffer heating sheet: spray a conductive adhesive on the surface of the heating sheet (8) prepared in step ①, and then stick the buffer layer (2) on the surface of the heating sheet (8) to obtain a buffer heating sheet;

[0061] The buffer layer (2) is metal foil; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com