Preparation method of double-layer junction electrode series tubular solid oxide fuel cell

A solid oxide, fuel cell technology, used in fuel cells, battery electrodes, circuits, etc., can solve the problems of high temperature operation of the coating stability battery, increase processing procedures, reduce production efficiency, etc., and achieve easy automation. , Long-term stability and service life improvement, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

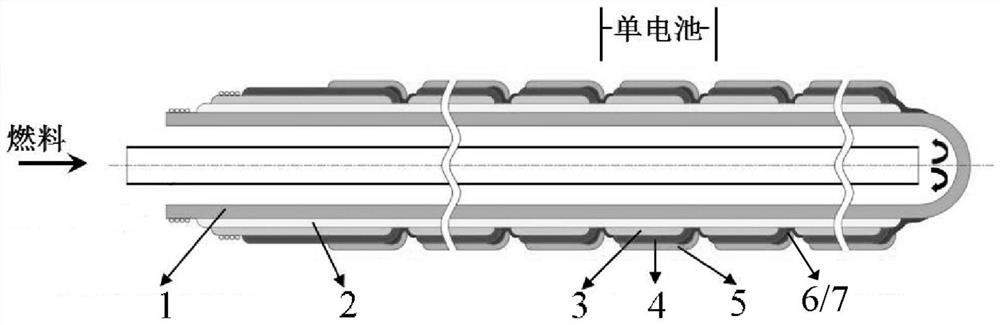

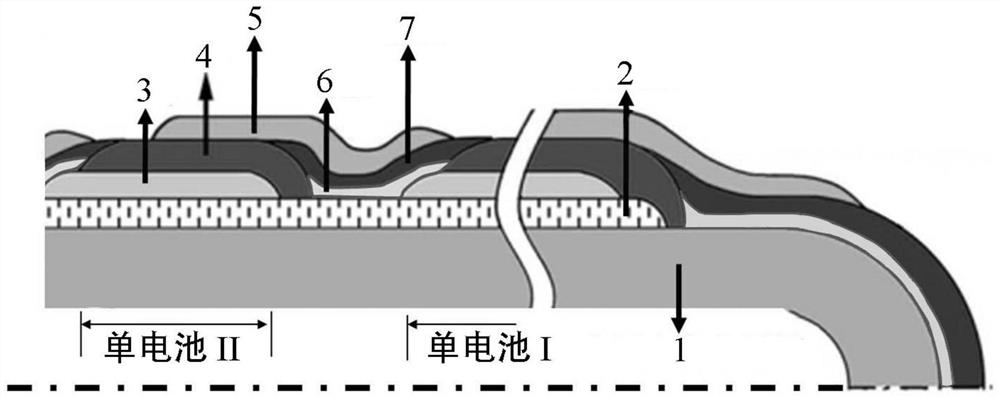

[0053] The basic structure of SOFC battery tube adopts such as figure 1 As shown, when the SOFC battery tube is manufactured, the anode layer 3, the electrolyte layer 4, the inner connection layer 6, the outer connection layer 7 and the cathode layer 5 are sequentially prepared from the inside to the outside on the outer surface of the porous insulating layer 2, and the dense electrolyte layer is prepared After layer 4, sintered La 0.3 Sr 0.7 TiO 3 Powder is used as the material of the inner connection layer 6, the substrate is preheated to above 400°C, and a dense ceramic coating is prepared by plasma spraying at a power of 30kW, the inner connection layer 6 overlaps the electrolyte layer 4 by 1-5mm in the lateral direction, and the thickness is 150μm; then , using La 0.8 Sr 0.2 CrO 3 Powder, the substrate is preheated to above 500°C, and the dense outer connection layer 7 is plasma sprayed under 40kW power. The outer connection layer 7 completely covers the inner connec...

Embodiment 2

[0055] The basic structure of SOFC battery tube adopts such as figure 1 As shown, when manufacturing the SOFC battery tube, on the outer surface of the porous insulating layer 2, an anode layer 3, an electrolyte layer 4, an inner connection layer 6, an outer connection layer 7 and a cathode layer 5 are sequentially prepared from the inside to the outside. After preparing the dense electrolyte layer 4, the sintered La 0.3 Sr 0.7 TiO 3 Powder is used as the material of the inner connection layer 6, the substrate is preheated to above 400°C, and a dense ceramic coating is prepared by plasma spraying at a power of 30kW, the inner connection layer 6 overlaps the electrolyte layer 4 by 1-5mm in the lateral direction, and the thickness is 150μm; then , using La 0.8 Ca 0.2 CrO 3 Powder, the substrate is preheated to above 450°C, and the dense outer connection layer 7 is plasma sprayed under 38kW power. The outer connection layer 7 completely covers the inner connection layer 6 an...

Embodiment 3

[0057] The basic structure of SOFC battery tube adopts such as figure 1 As shown, when manufacturing the SOFC battery tube, on the outer surface of the porous insulating layer 2, an anode layer 3, an electrolyte layer 4, an inner connection layer 6, an outer connection layer 7 and a cathode layer 5 are sequentially prepared from the inside to the outside. After preparing the dense electrolyte layer 4, the sintered La 0.3 Sr 0.7 TiO 3 The powder is used as the material of the inner connection layer 6, the substrate is preheated to above 400°C, and a dense ceramic coating is prepared by plasma spraying at a power of 30kW, the inner connection layer 6 overlaps the electrolyte layer 4 by 1-5mm in the lateral direction, and the thickness is 200μm; then , using La 0.8 Sr 0.2 MnO 3 powder, the substrate is preheated to above 350°C, and the dense outer connection layer 7 is plasma sprayed at a power of 35kW. The outer connection layer 7 completely covers the inner connection laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com