Integrated electric heating plate and preparation method

An integrated board, electric heating technology, applied in the field of building materials, can solve problems such as waste of energy, and achieve the effects of high heating efficiency, low production cost, and small heating power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

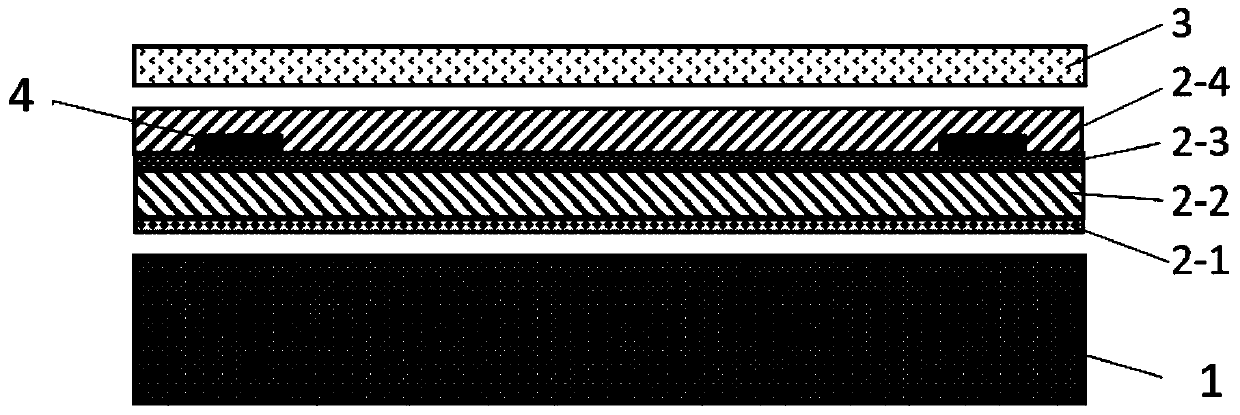

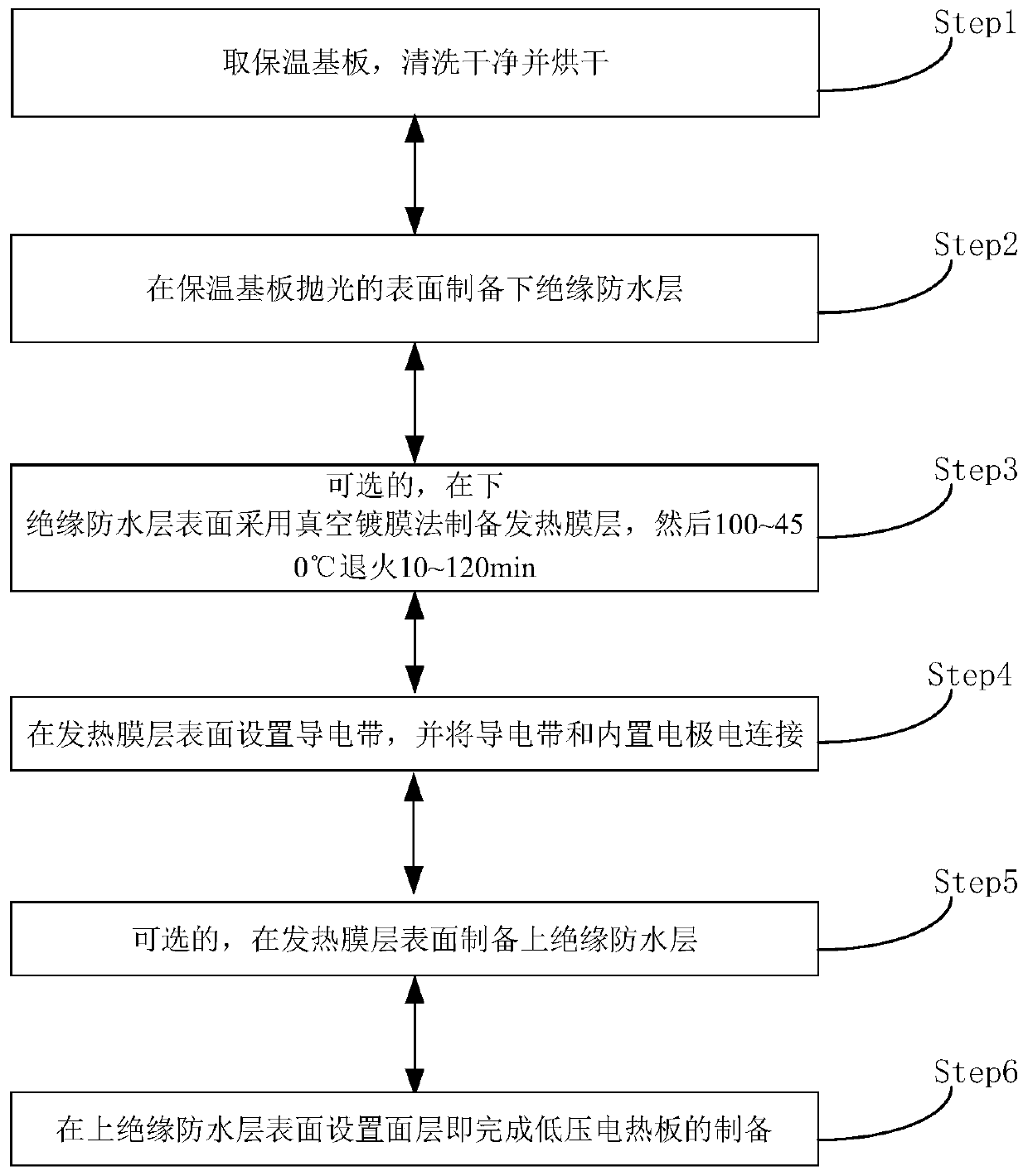

[0035] see figure 1 , an electric heating integrated board, the electric heating integrated board includes a thermal insulation base material 1, a heating film layer 2-3 and a surface layer 3; the thickness of the heating film layer 2-3 is between 50nm and 10 μm; the square resistance of the heating film layer Between 10~1000Ω / □.

[0036] During specific implementation, the above-mentioned heating film layer 2-3 is oxide or oxysulfide, and the material of the heating film layer 2-3 includes ZnO x S (1-x) , InO x S (1-x) , Sn x In (1-x) O, Zn x Mg (1-x) O, Zn x al (1-x) One or more of O.

[0037] During specific implementation, the above-mentioned heating film layer 2-3 is a carbon oxide, and the material of the heating film layer 2-3 includes SiO x C (1-x) .

[0038] During specific implementation, the above-mentioned heat-generating film layer 2-3 is a carbonitride compound, and the material of the heat-generating film layer 2-3 includes SiC x N (1-x) .

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com