System and method for synergistically treating construction waste by using cement kiln

A construction waste and co-processing technology, which is applied in cement production, etc., can solve the problems of poor applicability of construction waste products, high requirements for construction waste raw materials, and general system processing effects, etc., so as to enhance market competitiveness, reduce production costs, and improve cement production. The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

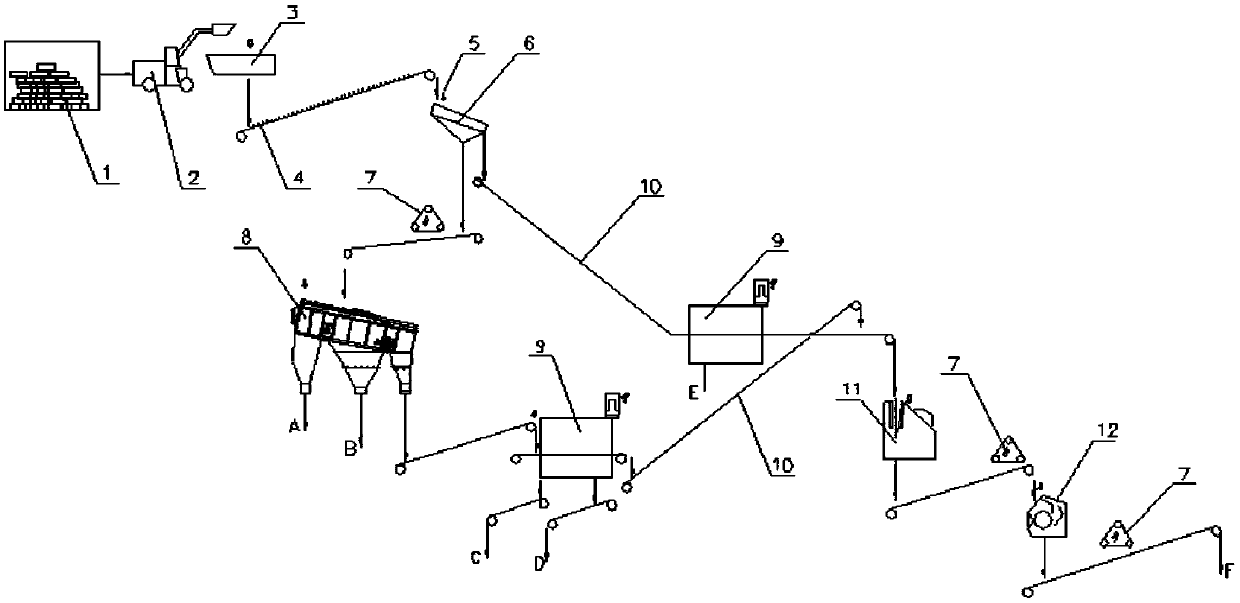

[0019] Further description will be made below in conjunction with drawings and embodiments.

[0020] A cement kiln cooperative processing construction waste system and method in this embodiment, the system includes a cement kiln cooperative processing system and a construction waste processing system. The cement kiln synergy system mainly sends the regenerated aggregate of construction waste as cement raw material to the raw material mill, and the screened dregs are used as cement raw material. Construction waste treatment mainly consists of storage, screening, iron removal and crushing. The storage system is a closed yard 1. The construction waste is stacked in the closed yard 1 after entering the site. The capacity of the closed yard 1 can store construction waste for 7 days; the construction waste in the closed yard 1 is stacked by the loader 2. The storage system transports the construction waste out of the closed yard through the loader 2, and is connected with the apron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com