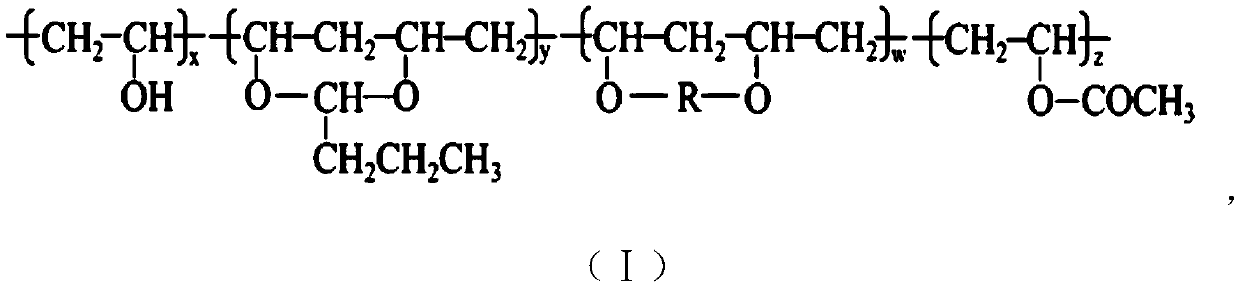

Heat-resistant low-viscosity polyvinyl acetal resin and preparation method thereof

A technology of polyvinyl acetal resin and polyvinyl alcohol, which is applied in the field of organic compounds and its preparation, can solve the problems of poor heat resistance of PVB resin, lack of heat-resistant groups, promotion, etc., and achieve stability over time Good, simple process, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

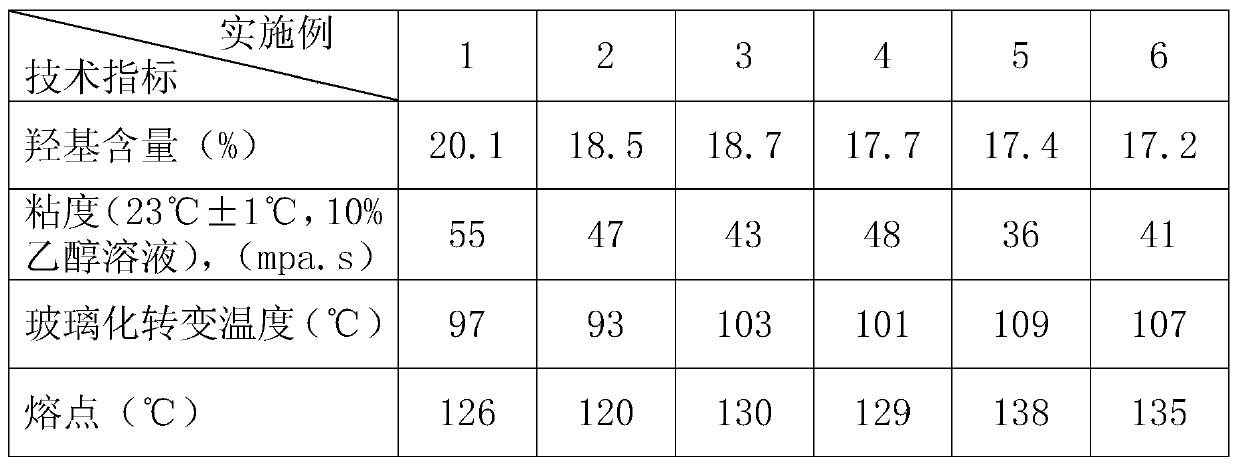

Embodiment 1

[0023] A preparation method of a heat-resistant low-viscosity polyvinyl acetal resin, the steps are: add 100 g of polyvinyl alcohol and 1000 g of deionized water into a dissolution kettle at room temperature, raise the temperature to 95° C., and stir to completely dissolve it into polyvinyl acetal resin. After filtering the vinyl alcohol aqueous solution, then lower the temperature to 40°C, add 52g of n-butyraldehyde, 6g of formaldehyde, 0.6g of antioxidant 1010, and stir at high speed for 30min to obtain a uniform mixed solution of polyvinyl alcohol / n-butyraldehyde; / N-butyraldehyde mixed solution and hydrochloric acid aqueous solution with a mass concentration of 1.0% at 20°C in a ratio of 100:20 by volume, within 8 minutes at the same time through their respective pipelines and continuously enter the tubular reactor with heating and cooling functions , reacted for 20 minutes, and then transferred all the materials to an aging kettle with a stirring speed of 100r / min and an i...

Embodiment 2

[0025] A method for preparing a heat-resistant low-viscosity polyvinyl acetal resin, the steps are: add 100 g of polyvinyl alcohol and 900 g of deionized water into a dissolution kettle at room temperature, raise the temperature to 93° C., and stir to completely dissolve it into polyvinyl acetal resin. After filtering the vinyl alcohol aqueous solution, then lower the temperature to 35°C, add 54g of n-butyraldehyde, 7g of acetaldehyde, 0.8g of antioxidant 1010, and stir at high speed for 30min to obtain a uniform polyvinyl alcohol / n-butyraldehyde mixed solution; Alcohol / n-butyraldehyde mixed solution and hydrochloric acid aqueous solution with a mass concentration of 1.0% are at 20°C in a ratio of 100:16 by volume, and enter the tubular reaction with heating and cooling functions continuously through their respective pipelines within 8 minutes at the same time device, reacted for 20min, and then transferred all materials to an aging kettle with a stirring speed of 100r / min and ...

Embodiment 3

[0027] A preparation method of a heat-resistant low-viscosity polyvinyl acetal resin, the steps are: add 100 g of polyvinyl alcohol and 900 g of deionized water into a dissolution kettle at room temperature, raise the temperature to 95° C., and stir to completely dissolve it into a polyvinyl acetal resin. After filtering the vinyl alcohol aqueous solution, then lower the temperature to 35°C, add 53g of n-butyraldehyde, 8g of benzaldehyde, and 0.7g of antioxidant 1076, and stir at high speed for 30min to obtain a uniform polyvinyl alcohol / n-butyraldehyde mixed solution; Alcohol / n-butyraldehyde mixed solution and hydrochloric acid aqueous solution with a mass concentration of 1.0% are at 20°C in a ratio of 100:20 by volume, and enter the tubular reaction with heating and cooling functions continuously through their respective pipelines within 8 minutes at the same time device, reacted for 20min, and then transferred all materials to an aging kettle with a stirring speed of 100r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com