Modified polylactic acid composite material capable of being quickly crystallized and preparation method thereof

A technology of crystallization modification and composite materials, applied in the field of polylactic acid composite materials, can solve the problems of the destruction of the full biodegradability of composite materials, change the nature of the modification of composite materials, etc. The effect of temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

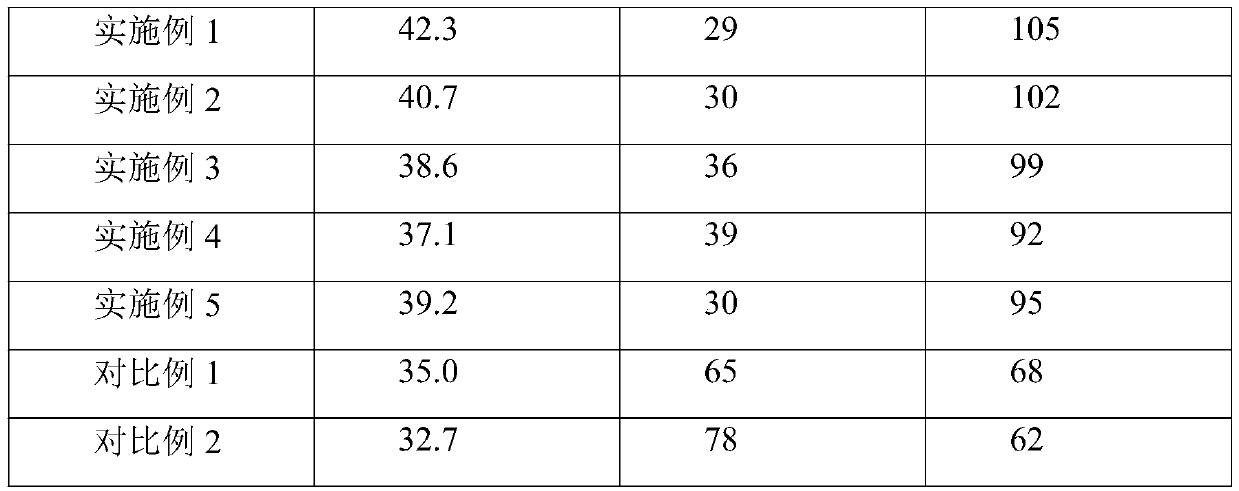

Embodiment 1

[0028] This embodiment provides a method for preparing a rapidly crystallizable modified polylactic acid composite material, comprising the following steps:

[0029] S1. Put the raw materials into a mixer and mix them. The mass fraction of each component in the raw materials is as follows: polylactic acid: 95%, 8000 mesh talcum powder: 4%, acetyl tributyl citrate: 0.3%, ethylene bis stearamide : 0.7%, the speed of the mixer is 1500rpm, and the time is 30min;

[0030] S2. Pour the mixture into the parallel twin-screw extruder and extrude and granulate by means of strands;

[0031] S3. Put the pellets into a mold for injection molding, the temperature of the injection mold is 105°C, the temperature difference between the inner surface of the mold is controlled at ±0.5°C, and the thickness of the injection molded product is 2mm.

Embodiment 2

[0033] This embodiment provides a method for preparing a rapidly crystallizable modified polylactic acid composite material, comprising the following steps:

[0034] S1. Put the raw materials into a mixer and mix them. The mass fraction of each component in the raw materials is as follows: Polylactic acid: 85%, 5000 mesh barium sulfate: 10%, adipic acid dihydrazide: 3%, ethylene bisstearamide : 2%, the mixer speed is 1400rpm, and the time is 15min;

[0035] S2. Pour the mixture into the parallel twin-screw extruder and extrude and granulate by means of strands;

[0036] S3. Put the pellets into a mold for injection molding, the temperature of the injection mold is 85°C, the temperature difference between the inner surface of the mold is controlled at ±2°C, and the thickness of the injection molded product is 2mm.

Embodiment 3

[0038] This embodiment provides a method for preparing a rapidly crystallizable modified polylactic acid composite material, comprising the following steps:

[0039] S1. Put the raw materials into a mixer and mix them. The mass fraction of each component in the raw materials is as follows: polylactic acid: 97.8%, 6000 mesh calcium carbonate: 0.1%, dibenzoyl phosphate amine: 2%, ethylene bis stearamide : 0.1%, the speed of the mixer is 1200rpm, and the time is 5min;

[0040] S2. Pour the mixture into the parallel twin-screw extruder and extrude and granulate by means of strands;

[0041] S3. Put the pellets into a mold for injection molding, the temperature of the injection mold is 130°C, the temperature difference between the inner surface of the mold is controlled at ±10°C, and the thickness of the injection molded product is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com