Gas purifying and filling positive and negative pressure gas circuit switching device and using method thereof

A gas purification and switching device technology, which is applied to the installation device of container structure, container filling method, container discharge method, etc., can solve the problems of filling gas quality, long operation process, frostbite of operators, etc., and achieve remote control Monitoring and switching control, shortening the switching time, and improving the effect of environmental protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

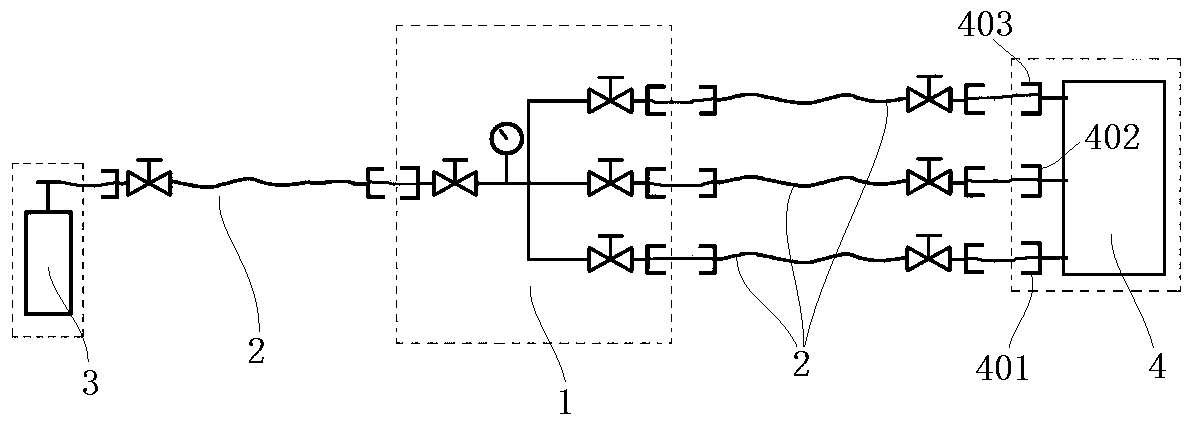

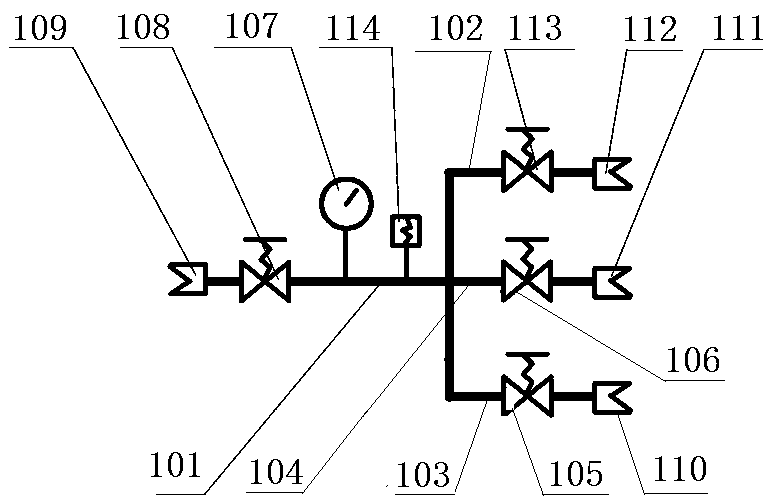

[0042] Such as Figure 1-3As shown, the positive and negative pressure gas path switching device for gas purification and filling includes a main gas path pipeline 101, a vacuum pressure gauge 107 is provided on the main gas path pipeline 101, and one end of the main gas path pipeline 101 is sequentially connected with a gas cylinder control valve 108 And the gas cylinder self-sealing joint 109, the gas cylinder self-sealing joint 109 is connected to the gas cylinder 3 through the detachable hose 2; the other end of the main gas pipeline 101 is provided with three branch pipelines, which are respectively a vacuum pipeline 102 and a recovery pipeline 104 And the filling pipeline 103, the vacuuming pipeline 102 is connected with a vacuuming control valve 113 and a vacuuming self-sealing joint 112, and the vacuuming self-sealing joint 112 is connected to the SF6 purification filling equipment 4 vacuuming port 403 through a detachable hose 2, and the recovery The pipeline 104 is c...

example 2

[0063] The difference from the above example is:

[0064] In order to realize remote switch control and simplify the switch operation, the gas cylinder control valve 108, the vacuum control valve 113, the recovery control valve 106, the filling control valve 105 and the hose valve 201 are all solenoid valves. Compared with mechanical valves, the control of solenoid valves is simpler, more convenient, and can be operated remotely.

[0065] In order to realize centralized control operation and improve operation safety, a pressure sensor 114 is also provided on the main gas pipeline 101 , and both the pressure sensor 114 and the solenoid valve are connected to the controller of the purification filling equipment 4 . By connecting the pressure sensor 114 and the solenoid valve to the controller of the purification filling equipment 4, the monitoring and operation can be concentrated at the position of the controller of the purification filling equipment 4, which can effectively re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com