Edible composition with filamentous fungi and bioreactor system for the cultivation thereof

A filamentous fungus, biological technology, applied in special-purpose bioreactors/fermenters, microbial-based methods, microorganisms, etc., can solve the problem of inaccessible or limited access to sterile facilities or/or need to be sealed aseptic System and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0150] Example 1: Growth of the strain Fusarium oxysporum strain MK7 and other fungi in static tray reactors.

[0151] Filamentous acidophilus Fusarium oxysporum strain MK 7, Ganoderma lucidum ( figure 1 A) Pleurotus officinale (Pearl oyster mushroom, figure 1 B: and blue oyster mushroom, figure 1 C), hydrangea (broccoli; figure 1 D), elm mushroom ( figure 1 E); big bald puffball ( figure 1 F) and Fusarium venenatum biomat, as described in PCT / US2017 / 020050.

Embodiment 2

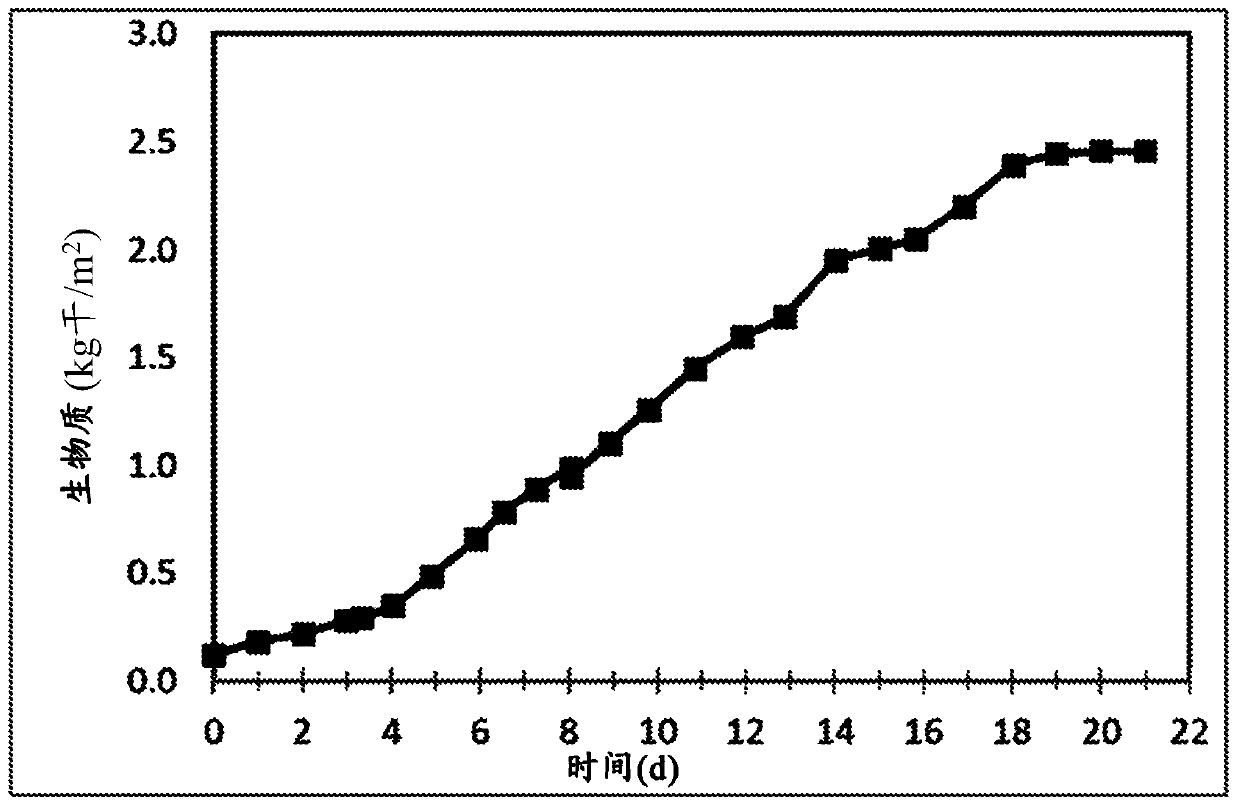

[0152] Example 2. Growth of Fusarium oxysporum MK7 biomats on nutrient medium changed daily (semi-static conditions).

[0153] Compact biomats of Fusarium oxysporum strain MK7 were grown approximately 3 cm thick in nutrient medium changed daily for 21 days. Used in 12.7x 17.8cm Sterile MK7-1 broth (described in PCT / US2017 / 020050) containing 7.5% glycerol at pH 3.0 in glass trays generated biomats. To start the experiment, 200 mL of nutrient medium was inoculated with a 5% (v / v) culture of Fusarium oxysporum strain MK7 during the late exponential growth phase as previously described in PCT / US2017 / 020050. 200 mL of inoculated medium was added to each of three sterile trays lined with sterile coarse nylon mesh screens. The culture was incubated undisturbed at room temperature (approximately 22°C) for 4 days to form an initial biocushion that formed at the liquid surface. After 4 days of growth, gently lift the biomat out of the tray using a nylon mesh screen and tilt it at a ...

Embodiment 3

[0154] Example 3. Growth of biomats under continuous flow conditions.

[0155] Fabricate a continuous flow bioreactor system to demonstrate the growth of biomats on the surface of flowing liquid media. The system is made of a 2.44 m long transparent plastic cover sheet with a series of corrugations used as flow channels ( image 3 ). The ends of each channel were capped with silicon (100% silicone, DAP Products Inc., Baltimore, MD) to allow liquid to remain within the channel. Flow through the channel is facilitated by delivering liquid medium via a peristaltic pump to one end of the channel, and the liquid exits the other end of the channel through a hole in the bottom of the channel. The entire plastic cover plate system is sloped at an angle of 1 cm rise per 1 m run so that about 500 mL of liquid can be retained in each channel and the constant flow is a function of liquid volume and slope angle.

[0156] Sterilize the plate system and use A sample plastic wrap is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com