Multilayer structural artificial meat

A multi-layer structure, artificial meat technology, applied in the field of food processing, can solve the problems of easy loss, uneven and lack of gravy, and achieve the effect of preventing gravy from overflowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

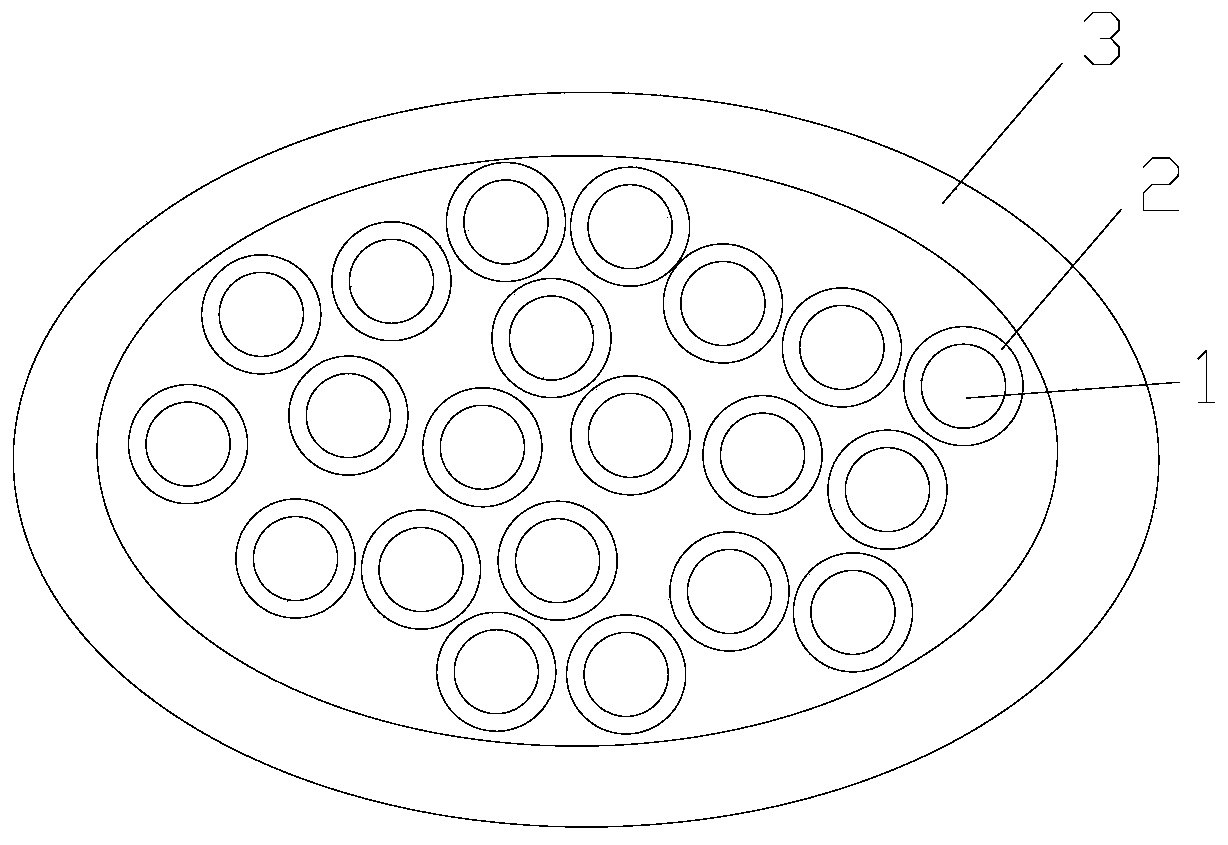

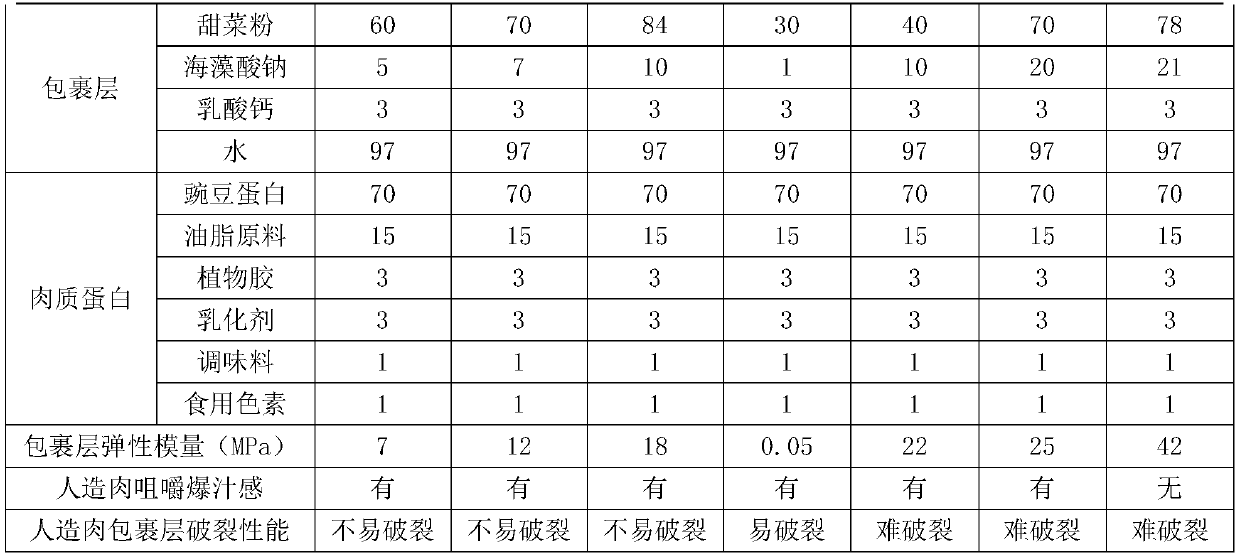

[0034] In parts by weight, mix 60-98.5 parts of natural plant extracts and / or plant proteins, 0.5-10 parts of sodium alginate, and 0.01-99.5 parts of gravy to make drops; add 1-10 parts of curing agent to 90- Dissolve 99.8 parts of water to make a solidifying agent solution; drop the prepared dripping material into the prepared curing agent solution, and take out the dripping material to solidify into beads to obtain a wrapping layer that wraps the gravy. The diameter of the wrapping layer is 1mm-20mm. Using MACH-1 TM The elastic modulus of the coating layer measured by the multifunctional multi-axial tissue material micromechanics and electromechanical characteristics testing system is 0.01-20MPa.

[0035] According to parts by weight, mix 20-80 parts of vegetable protein, 10-20 parts of oil raw materials, 1-5 parts of vegetable gum, 1-5 parts of seasoning, 1-5 parts of emulsifier, and 1-5 parts of food coloring. Mixture; mix the mixture at a temperature of 30-150°C, a humid...

Embodiment 2

[0038] In parts by weight, mix 80-90 parts of natural plant extracts and / or plant proteins, 2-10 parts of konjac powder, and 48-68 parts of gravy to make drops; add 1 part of curing agent to 99 parts of water, dissolve Prepare a curing agent solution; drop the prepared drop material into the prepared curing agent solution, and take out the coating layer that wraps the gravy after the drop material is solidified into beads, and the diameter of the coating layer is 2mm-20mm. Using MACH-1 TM The elastic modulus of the cladding layer is determined to be 1-20 MPa by the multifunctional multi-axial tissue material micromechanical and electromechanical characteristic testing system.

[0039] According to parts by weight, mix 20-80 parts of vegetable protein, 10-20 parts of oil raw materials, 1-5 parts of vegetable gum, 1-5 parts of seasoning, 1-5 parts of emulsifier, and 1-5 parts of food coloring. Mixture; mix the mixture at a temperature of 30-80°C, a humidity of 30%-70%, and a pr...

Embodiment 3

[0042] By weight, 85 parts of plant beetroot juice vegetable protein, 0.5 part of sodium alginate, and 14.5 parts of gravy are mixed uniformly to make dripping material; 4 parts of calcium chloride are added to 99 parts of water, and dissolved to make a solidifying agent solution; The prepared dripping material is dripped into the prepared solidifying agent solution, and the dripping material is solidified into beads, and then taken out to obtain a wrapping layer wrapping the gravy, and the diameter of the wrapping layer is 20mm. Using MACH-1 TM The elastic modulus of the cladding layer was determined to be 8 MPa by the multifunctional multi-axial tissue material micromechanical and electromechanical characteristic testing system.

[0043] In parts by weight, mix 68-80 parts of vegetable protein, 10-15 parts of oil raw materials, 1-3 parts of vegetable gum, 1-3 parts of spices, 1-3 parts of emulsifier, and 1-3 parts of food coloring to make a mixture material; mix the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com