Preparation method of superfine irregular silver powder

An irregular and ultra-fine silver technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of hard agglomeration, soft agglomeration, poor dispersion, etc., and achieve the goal of suppressing hard agglomeration, improving dispersion and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A preparation method of superfine irregular silver powder, comprising the following steps:

[0042] Step 1: Preparation of oxidation solution, weighing one or more solids of quantitative metal nitrate, chlorate or sulfate and dissolving them in deionized water, keeping the concentration of metal ions in the oxidation solution at 0.1-5 mol / liter, Fully stir until the solid is completely dissolved and maintain a constant temperature of 15-50°C;

[0043]Step 2: To generate intermediates, measure quantitative ammonia water with a concentration of 1% to 28% or sodium hydroxide with a concentration of 1% to 32%. Add one or two alkaline liquids to the oxidation solution to generate precious metals For oxides or complexes, the flow rate is controlled at 0.1L-100L / Min during the addition process, fully stirred, and kept at a constant temperature of 15-50°C;

[0044] Step 3: Oxidation-reduction reaction, measure the quantitative reducing solution and add it to the oxidizing solu...

Embodiment 1

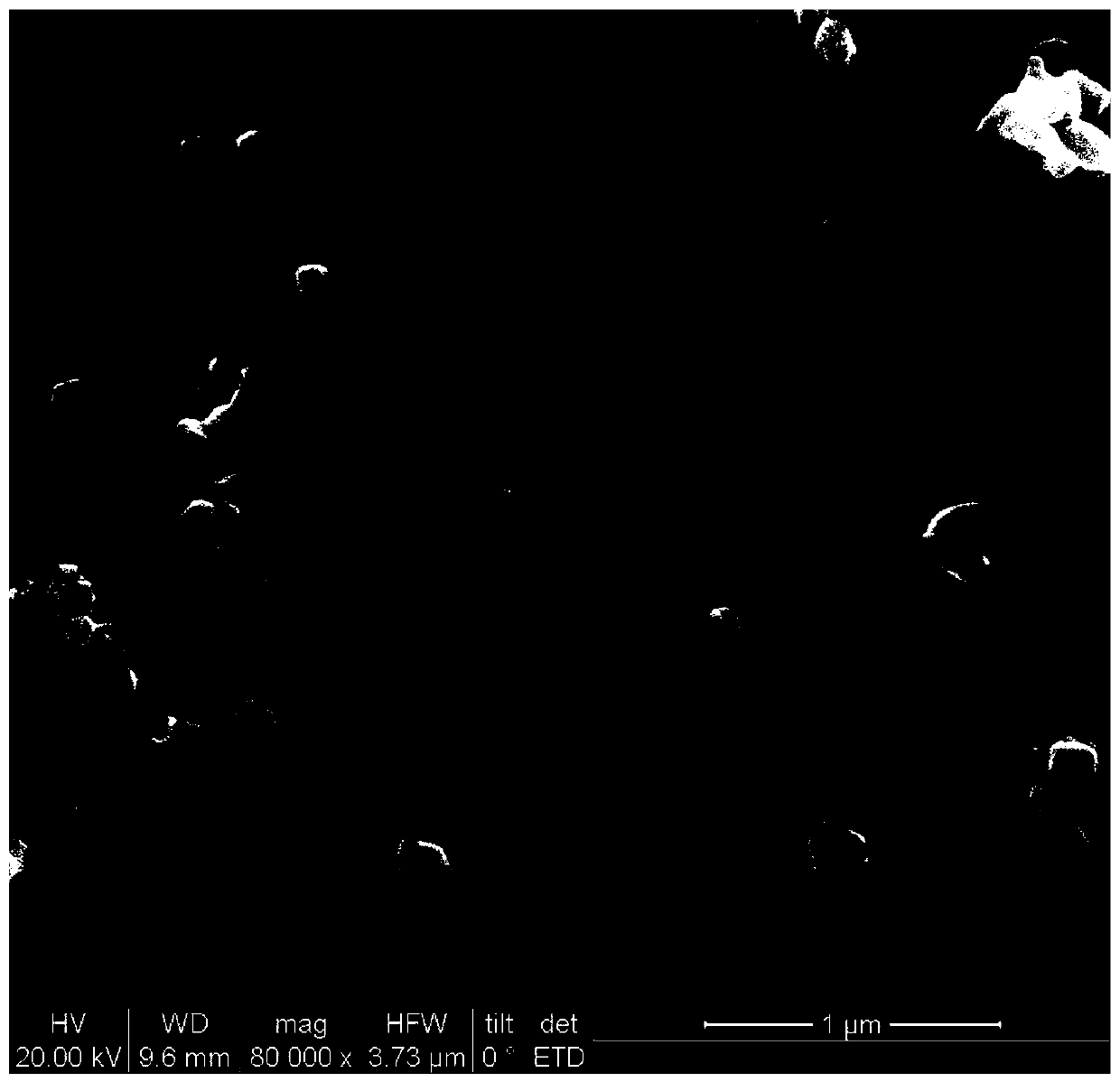

[0053] like figure 1 Shown, the preparation method of described a kind of superfine irregular silver powder, comprises the following steps:

[0054] Weigh 1 kg of silver nitrate and dissolve it in 7 liters of deionized water, wait until it is completely dissolved, then quantitatively add 0.56 liters of 32% sodium hydroxide to the solution, the flow rate is 0.1L / min, and the reaction generates silver oxide;

[0055] Measure 0.17 liters of 55% hydrazine hydrate solution, pump it quantitatively into the newly generated silver oxide solution, and control the flow rate at 0.1L / min. After the reaction is complete, discharge, clean and suction filter;

[0056] Finally, use alcohol as a dispersion liquid, add 10 grams of triethanolamine as a protective agent for high-speed dispersion for 20 minutes, drain it and send it to an oven for drying, and the drying temperature is controlled at 58°C;

[0057] The dried powder is then subjected to jet milling, the jet milling pressure is 0.6MP...

Embodiment 2

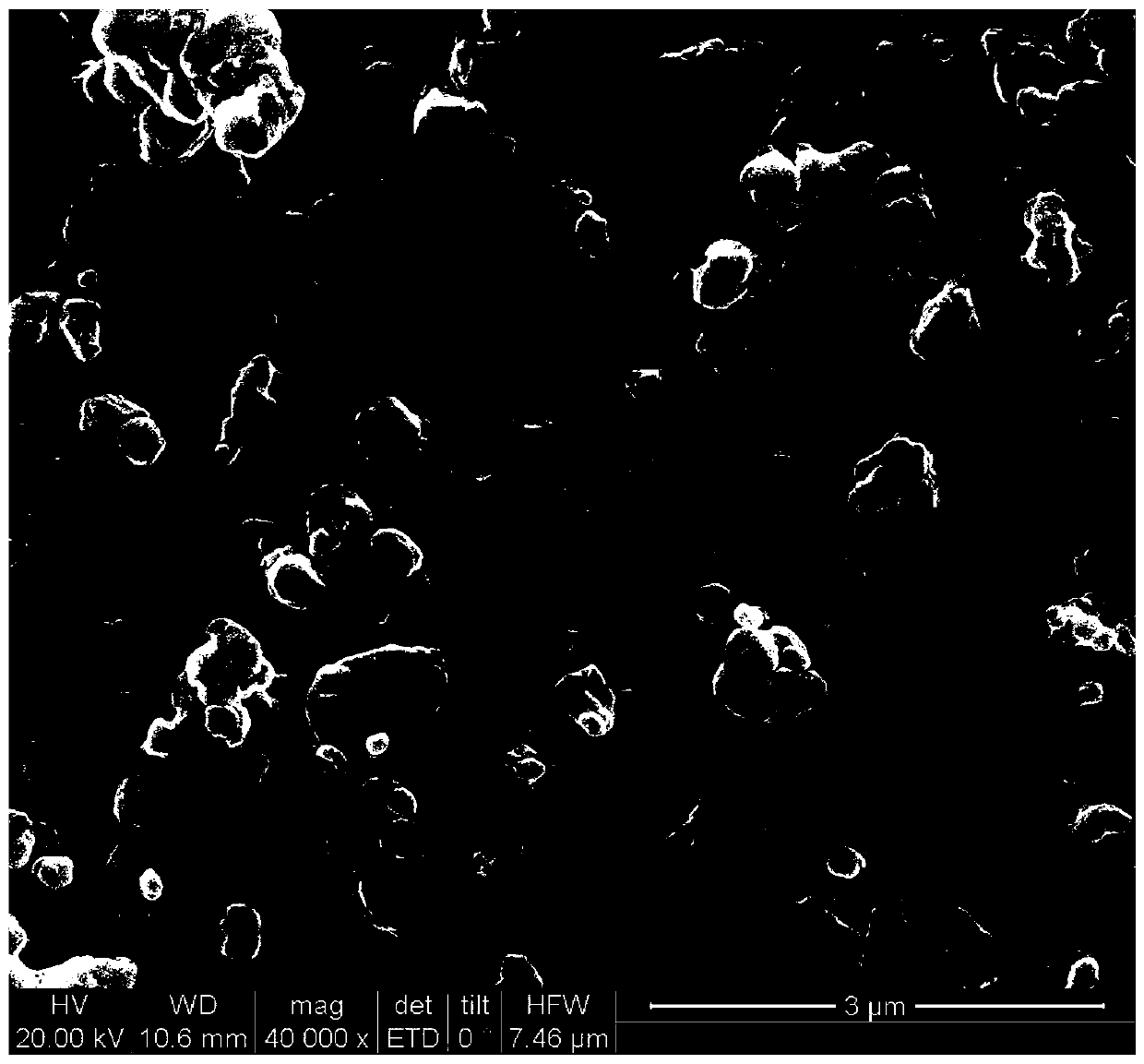

[0059] like figure 2 Shown, a kind of preparation method of superfine irregular silver powder comprises the following steps:

[0060] Weigh 2.5 kilograms of silver nitrate and dissolve it in 20 liters of deionized water, wait for complete dissolution, then quantitatively add 1.5 liters of 32% sodium hydroxide to the solution, the flow rate is 0.1L / min, and the reaction generates silver oxide;

[0061] Measure 1.37KG of ascorbic acid, dissolve it in 15 liters of deionized water, pump it quantitatively into the newly generated silver oxide solution, and control the flow rate at 1L / min. After the reaction is complete, remove the material for cleaning and suction filtration;

[0062] Finally, use alcohol as the dispersion liquid, add 30 grams of Tween TW for high-speed dispersion for 20 minutes, drain it and send it to an oven for drying, and the drying temperature is controlled at 60°C;

[0063] The dried powder is then subjected to jet milling, the jet milling pressure is 0.6M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap