Plastic tray and preparation process thereof

A technology of plastic pallets and polyethylene resin, applied in the field of plastic product production, can solve the problems of poor anti-skid performance, easy falling and damage of goods, etc., and achieve the effect of improving anti-skid performance, avoiding slipping and improving static friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

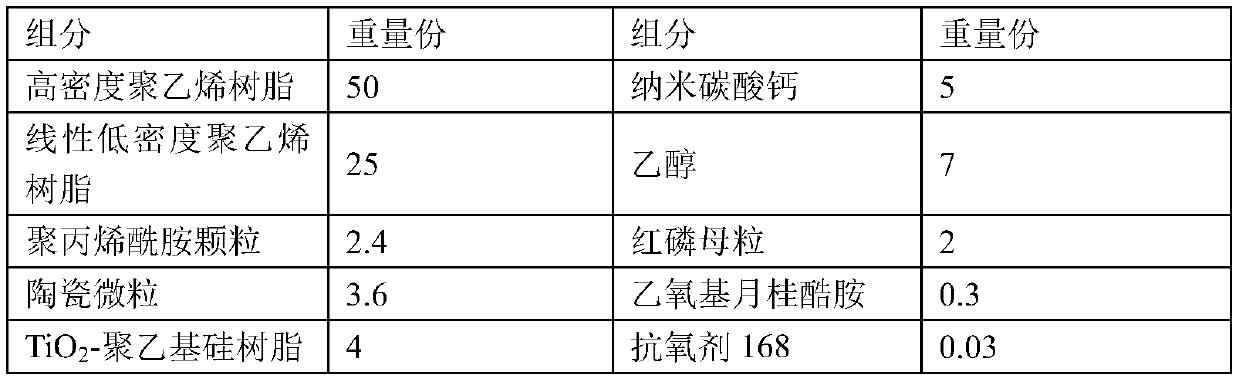

[0044] Embodiment 1 is a plastic pallet disclosed by the present invention and its preparation process. The plastic pallet includes the following components by weight:

[0045]

[0046] The particle size of polyacrylamide particles is 3.5mm, and the particle size of ceramic particles is 2.5mm;

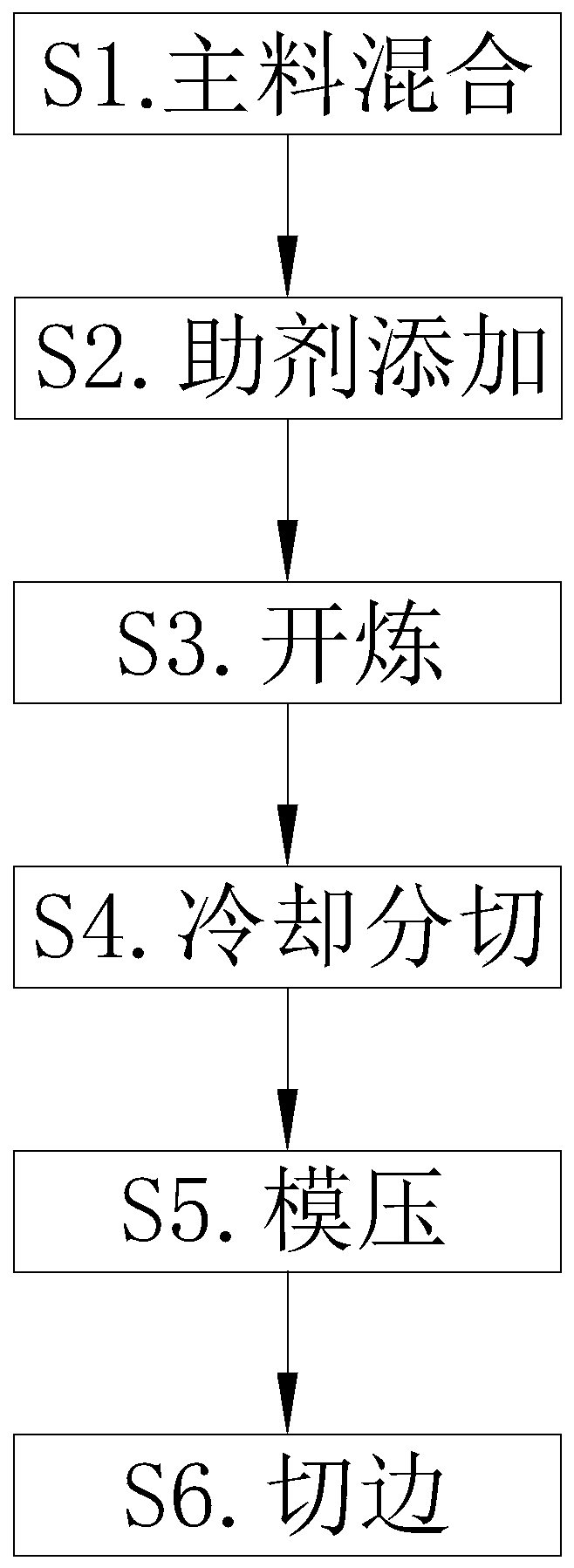

[0047] The preparation process of the plastic tray specifically includes the following steps:

[0048]S1. Mixing of main ingredients: Weigh the main ingredients according to the formula, mix high-density polyethylene resin, linear low-density polyethylene resin, polyacrylamide particles, ceramic particles, ethanol, TiO 2 - Add polyethylsilicone resin and nano-calcium carbonate to a mixer and stir to mix evenly. The stirring temperature is 40°C and the stirring time is 8 minutes;

[0049] S2. Addition of additives: Add red phosphorus masterbatch, ethoxylauramide and antioxidant 168 into the mixer and continue stirring for 5 minutes to obtain a mixture;

[0050] S3. Smelting: carry ...

Embodiment 2

[0053] Embodiment 2 is a plastic pallet disclosed by the present invention and its preparation process. The plastic pallet includes the following components by weight:

[0054]

[0055] The particle size of polyacrylamide particles is 3.5mm, and the particle size of ceramic particles is 2.5mm;

[0056] The preparation process of the plastic tray is the same as in Example 1.

Embodiment 3

[0057] Embodiment 3 is a plastic tray disclosed by the present invention and its preparation process. The plastic tray includes the following components by weight:

[0058]

[0059] The particle size of polyacrylamide particles is 3.5mm, and the particle size of ceramic particles is 2.5mm;

[0060] The preparation process of the plastic tray is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com